Pipe fitting with function of being capable of changing diameter and flow velocity

A technology of pipe fittings and flow rate, applied in the field of elbow pipe fittings for adjusting the diameter of elbow pipe fittings, can solve the problems of deformation of elbow pipe fittings, changing the diameter and flow rate, unable to meet the needs of various transmissions, etc., so as to increase the service life and reduce the direct The effect of wear and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

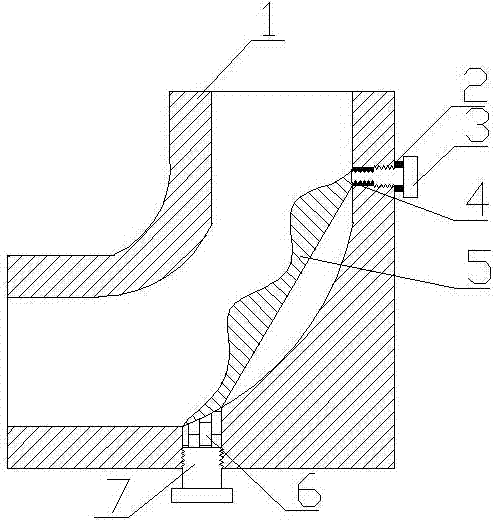

[0011] Such as figure 1 As shown, a pipe fitting with the function of changing the caliber and flow velocity, including elbow pipe fitting 1, insulating rubber gasket 2, bolt 3, stainless steel sealing block 4, wave-shaped adjustment plate 5, spacer 6 and bolt 7, elbow pipe fitting 1 is provided with a wave-shaped adjustment plate 5, the lower end of the wave-shaped adjustment plate 5 is connected with the cushion block 6, the cushion block 6 is embedded in the elbow pipe fitting 1, the bolt 7 is arranged under the cushion block 6, and the upper end of the wave-shaped adjustment plate 5 is connected with the bolt 6 is fixedly connected, the joint between the bolt 6 and the wave-shaped adjustment plate 5 is provided with a stainless steel sealing block 4, the bolt 6 passes through the stainless steel sealing block 4, and the bolt 6 is covered with an insulating rubber washer 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com