Accelerometer fault diagnosing and detecting method

A technology of accelerometer and detection method, applied in speed/acceleration/shock measurement, test/calibration of speed/acceleration/shock measurement equipment, measurement device, etc., which can solve the problems of low efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A method for error diagnosis and detection of an accelerometer in a three-dimensional space, the specific steps of which are as follows:

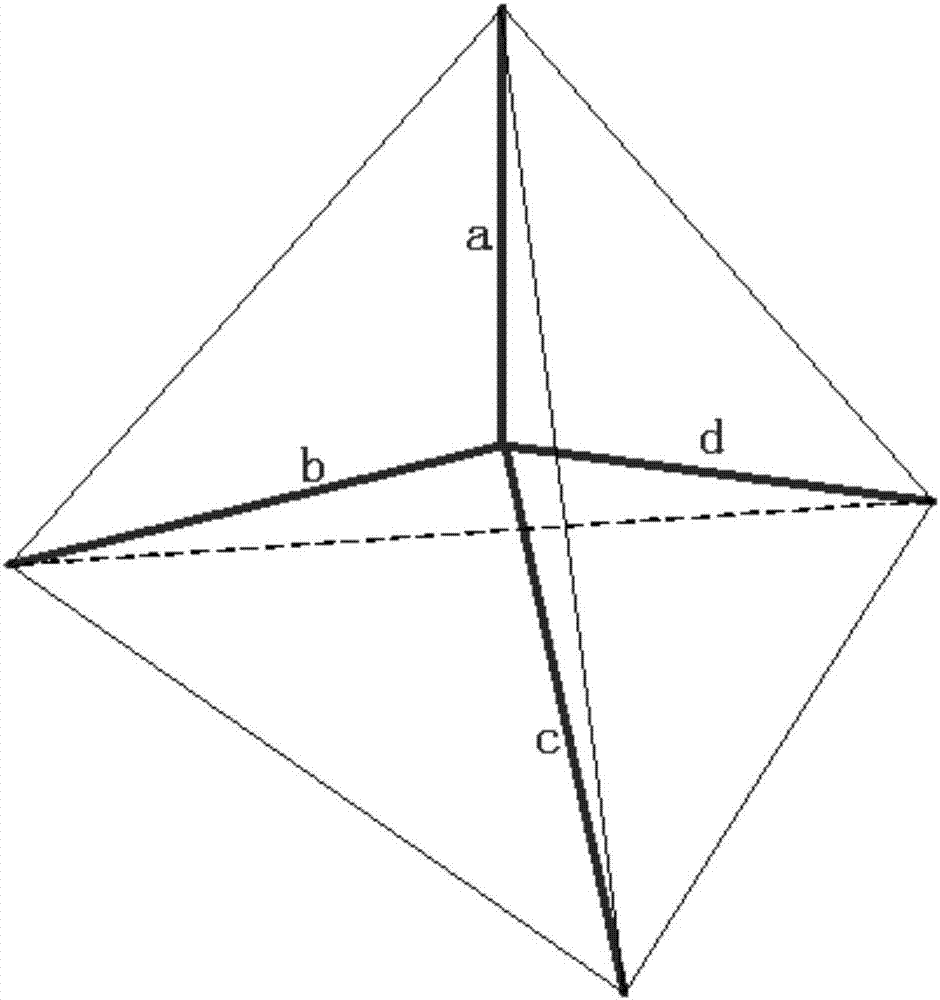

[0028] (1): Use the center of the regular tetrahedron and each end point to form a non-orthogonal four-axis (a, b, c, d); use the center of gravity as the starting point to obtain the vector data of a, b, c, and d;

[0029] (2): Taking a as a benchmark, perform vector decomposition on b, c, and d, and obtain the vector value on the straight line where the axis a is located;

[0030] (3): Calculate the vector sum of b, c, and d in the direction of axis a, and compare it with the actual measurement a;

[0031] (4): If it matches, the result is feasible, if it does not match, the result is not credible;

[0032] (5): A series of consecutive data results are unreliable, that is, the diagnosis and detection device fails, an error indication is issued, and the system is prompted to replace or scrap the device.

Embodiment 2

[0034] A method for error diagnosis and detection of an accelerometer in a three-dimensional space, the specific steps of which are as follows:

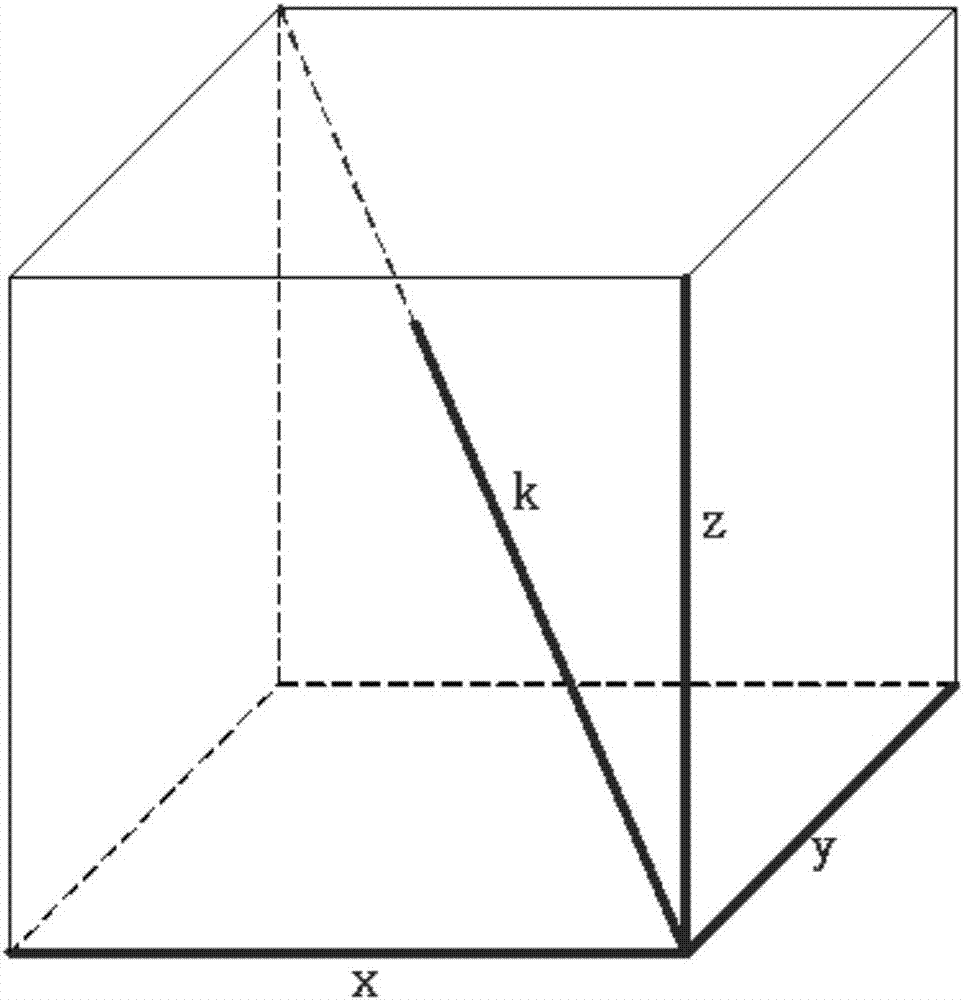

[0035] (1): Use a cube to connect three sides and a pair of fixed points to form a local non-orthogonal four-axis (x, y, z, k); take the pair of fixed points as the starting point to obtain the vector data of (x, y, z, k);

[0036] (2): With k as a benchmark, vector decomposition is performed on x, y, and z to obtain the vector value on the straight line where the axis k is located;

[0037] (3): Calculate the vector sum of x, y, z in the direction of axis k, and compare it with the actual measurement k;

[0038] (4): If it matches, the result is feasible, if it does not match, the result is not credible;

[0039] (5): A series of consecutive data results are unreliable, that is, the diagnosis and detection device fails, an error indication is issued, and the system is prompted to replace or scrap the device.

Embodiment 3

[0041] A method for error diagnosis and detection of an accelerometer in a two-dimensional space, the specific steps of which are as follows:

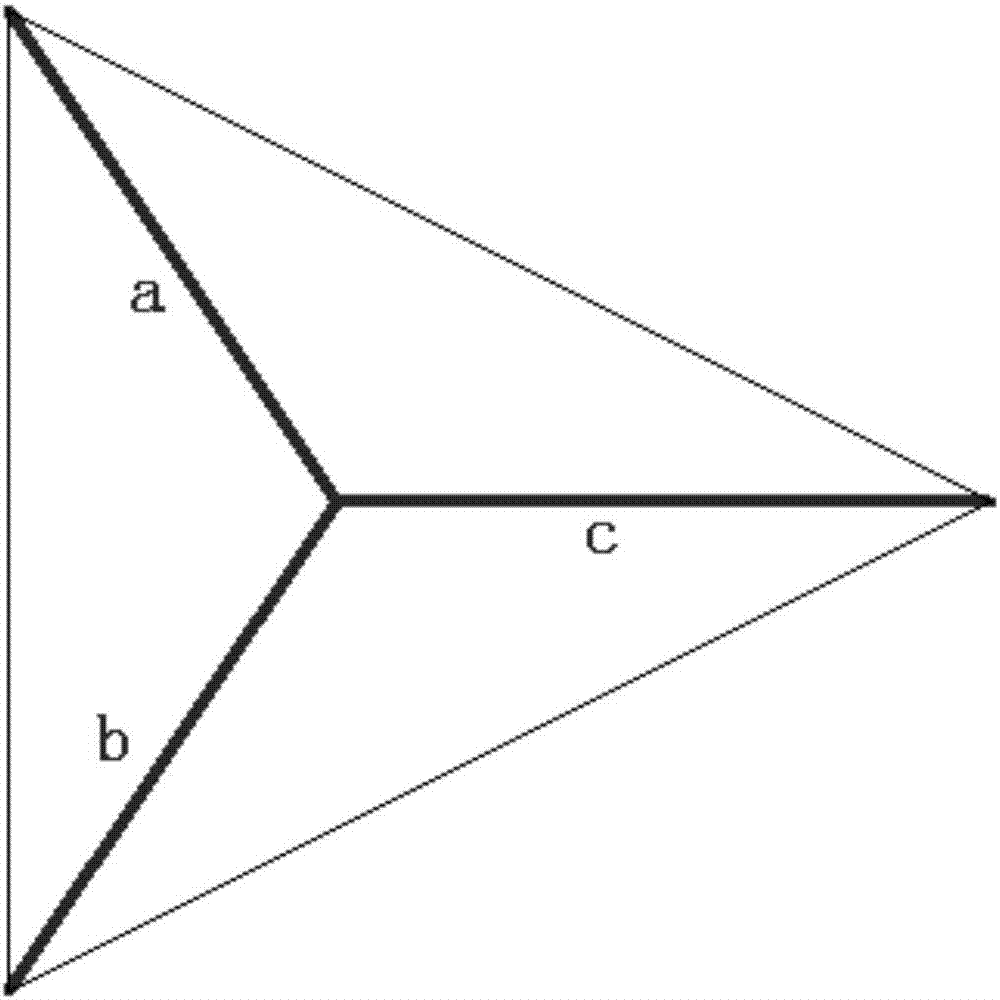

[0042] (1): Use the non-orthogonal three axes (a, b, c) formed by the center of the equilateral triangle and each end point to obtain the vector data of a, b, and c;

[0043] (2): Taking a as a benchmark, perform vector decomposition on b and c, and obtain the vector value on the straight line where the axis a is located;

[0044] (3): Calculate the vector sum of b and c in the direction of axis a, and compare it with the actual measurement of a;

[0045] (4): If it matches, the result is feasible, if it does not match, the result is not credible;

[0046] (5): A series of consecutive data results are unreliable, that is, the diagnosis and detection device fails, an error indication is issued, and the system is prompted to replace or scrap the device.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com