A new resistance installer

A mounter and resistor technology, applied in the direction of resistor installation/support, resistor terminal/electrode, device to prevent contact with live contacts, etc. To achieve the effect of convenient repeated installation and use, improve the safety of use, and prevent accidental electric shock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

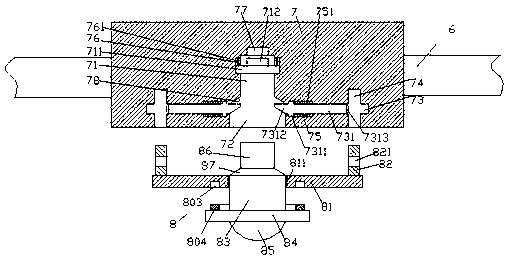

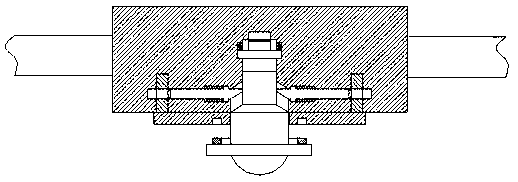

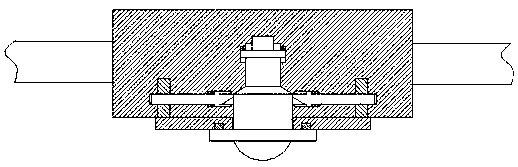

[0022] Such as Figure 1-Figure 5 As shown, a new resistance installer of the present invention includes a wire 6, a series seat 7 and a resistance component 8 used to cooperate with the series seat 7, and the series seat 7 is connected in series at the middle end of the wire 6 Two sets of suction cups 70 are evenly arranged on the rear end surface of the series seat 7 in the up and down direction, and the suction cups 70 are used to absorb and fix the series seat 7, so that the device is more stable during operation. The end is provided with a first sliding groove 71, the bottom of the first sliding groove 71 is provided with a second sliding groove 72, and the inner top wall of the series seat 7 on the top of the first sliding groove 71 is provided with There is an electrification chamber 77, and the inner wall of the series seat 7 on both sides of the first sliding groove 71 is provided with a third sliding groove 76, and a pressing plate 711 is slidingly fitted and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com