Method of manufacturing concrete structural blocks for use in wind turbine towers

A technology of wind turbines and concrete structures, which is applied in the assembly of wind turbines, the configuration of installation/support of wind turbines, wind power generation, etc., and can solve the problems of complex implementation and long time consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

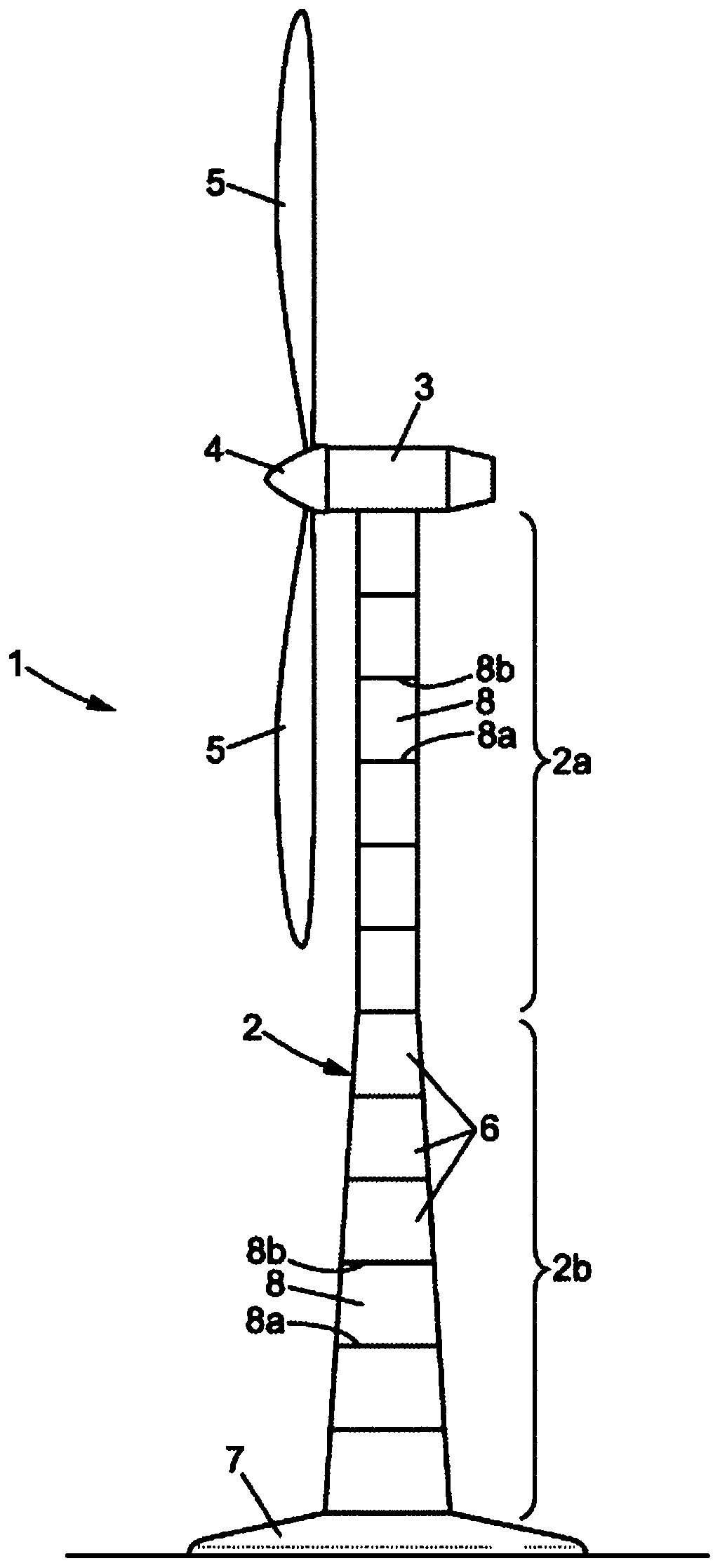

[0037] Such as figure 1 As shown, a wind turbine 1 comprises a tower 2 topped with a nacelle 3 and a rotor 4 comprising a plurality of blades 5 .

[0038] The tower 2 comprises a plurality of blocks 6 stacked on top of each other, thereby giving the tower 2 a generally elongated shape.

[0039] In the rest of the description, the tower 2 is considered to extend in a vertical direction.

[0040] The tower 2 is rigidly fixed to the foundation or foundation plate 7 .

[0041] The height of block 6 is preferably identical.

[0042] Each block 6 is constructed using a material such as reinforced concrete.

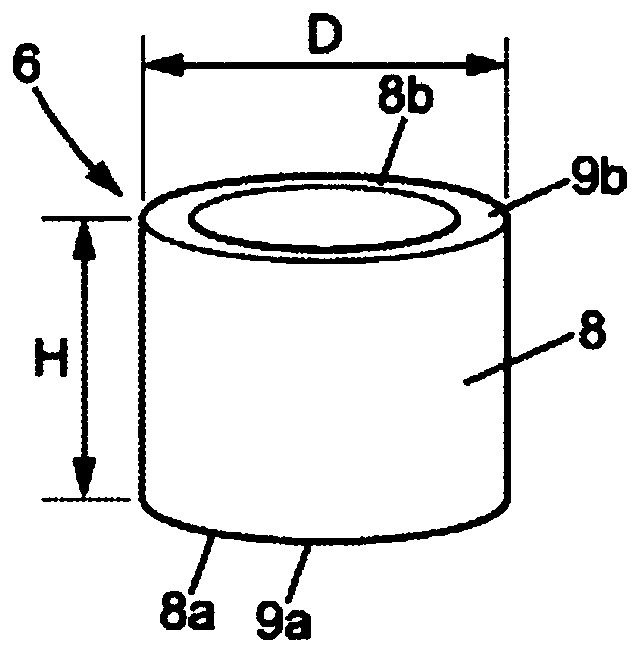

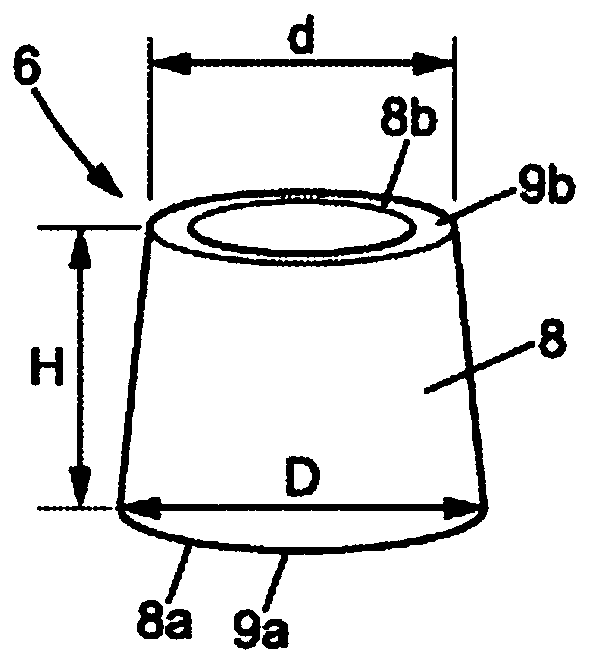

[0043] Such as figure 1 It can be seen that each block 6 of the upper part 2a is generally cylindrical, while each block 6 of the lower part 2b is generally conical.

[0044] Of course, the invention is not only applicable to the tower 2 shown, but may also be applicable to other tower forms, such as towers consisting only of cylindrical blocks or towers consisting only of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com