Plasma exhaust gas purification

A plasma and plasma source technology, applied in the field of plasma exhaust gas purification, can solve problems such as viscous failure, and achieve the effect of increasing service life and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

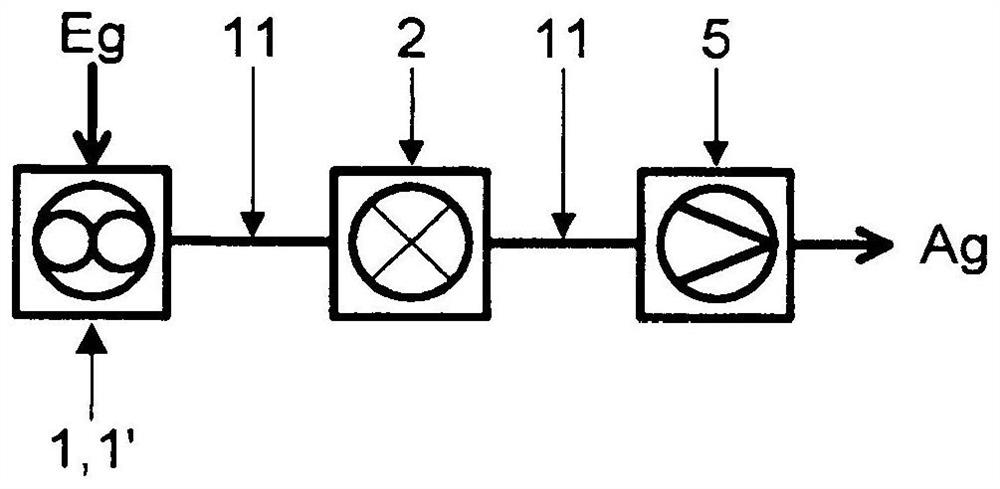

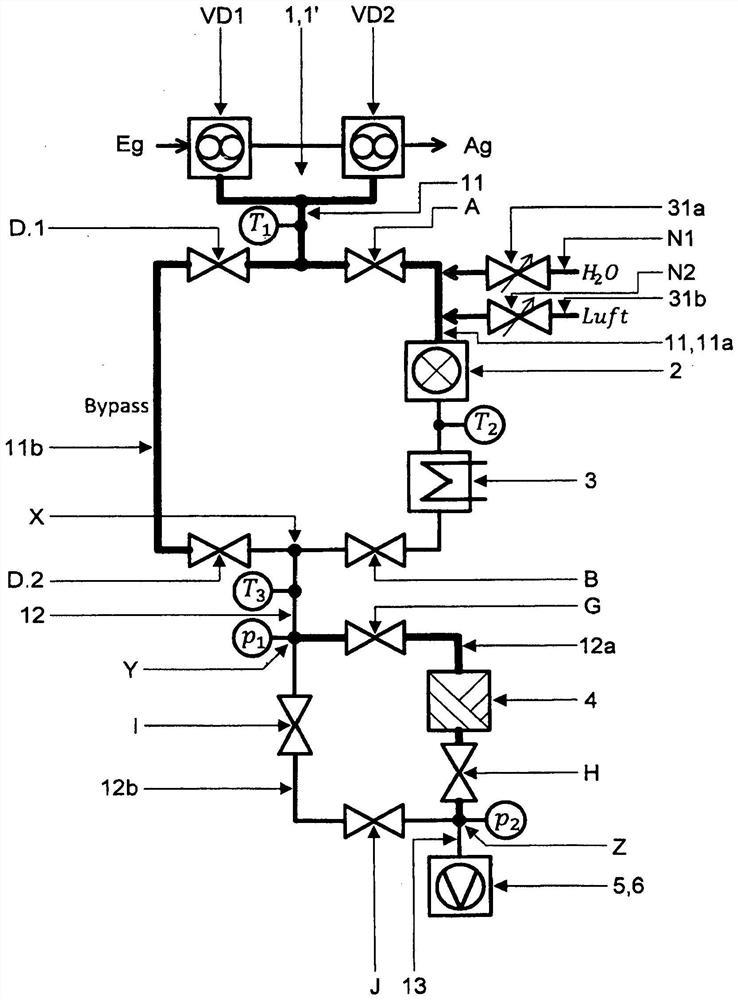

[0090] The following reference figure 1 The basic principle of the present invention is further explained.

[0091] here figure 1 A plasticizing unit 1, for example in the form of an extruder or, for example, in the form of a twin extruder 1.1', a plasma source 2 connected downstream and a further vacuum device 5 connected downstream of the plasma source 2 are shown in the schematic diagram, The vacuum system is also partly referred to as vacuum system 5 . The whole arrangement is interconnected by conduits 11 (pipes).

[0092] thus, figure 1 Again, the simplest conceivable configuration of the arrangement according to the invention is given, in which the mentioned plasma source 2 is available directly after the extruder 1 , 1 ′ and any separation is made superfluous here.

[0093] according to figure 1 The corresponding plasticizing unit 1 of the first embodiment comprises, for example, an extruder 1 , 1 ′ which, as is known, generally has at least one or two (or more) p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com