Aqueous emulsion and adhesive in which same is used

一种水性乳液、乳液聚合的技术,应用在胶粘剂、粘合剂类型、酯共聚物粘合剂等方向,能够解决覆膜耐水性降低、乳液机械稳定性降低等问题,达到覆膜耐水性优异、初始粘接性优异、粘接耐久性优异的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

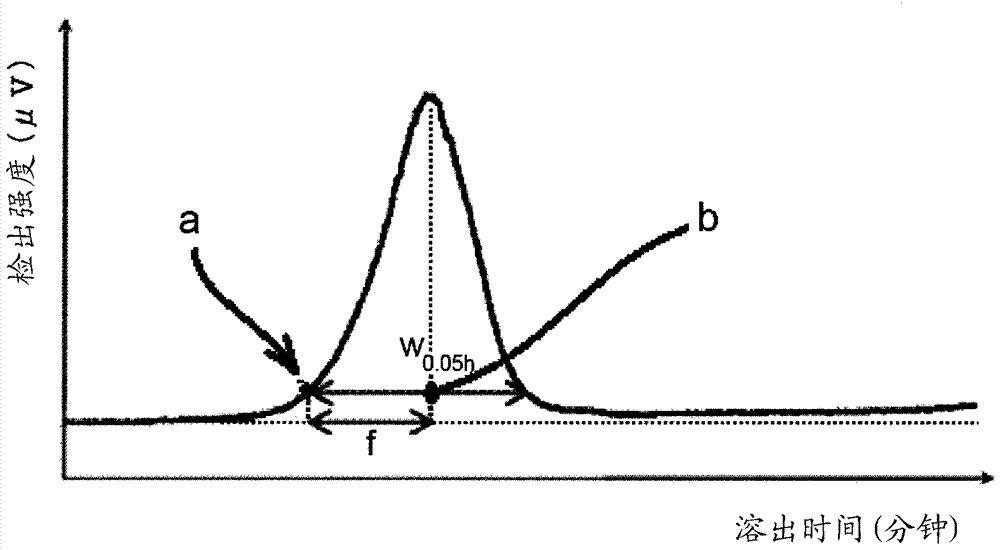

[0048] The method for preparing the aqueous emulsion of the present invention is not particularly limited, and examples thereof include the following method: in the presence of 0.5 to 40 parts by mass of the specific PVA (dispersant) described later with respect to 100 parts by mass of the above-mentioned ethylenically unsaturated monomer A method of performing emulsion polymerization by appropriately selecting a polymerization initiator. By such emulsion polymerization, an aqueous emulsion in which a part of the PVA as an emulsion polymerization dispersant is adsorbed on the surface of a polymer containing an ethylenically unsaturated monomer unit as a dispersoid can be obtained. Part of the PVA used as a dispersant in emulsion polymerization functions as a dispersant as described above, and the remaining PVA not adsorbed to the dispersoid exists in the aqueous emulsion as free PVA. It is considered that the PVA freely present in the aqueous emulsion (free PVA) significantly ...

Embodiment 1

[0168] (Manufacture of water-based emulsion)

[0169] 258.1 g of ion-exchanged water and 18.9 g of PVA-1 were put into a 1 L glass polymerization vessel equipped with a reflux condenser, dropping funnel, thermometer, and nitrogen blowing port, and were completely dissolved at 95° C. to obtain a PVA aqueous solution. Next, after cooling and replacing the PVA aqueous solution with nitrogen, 25.2 g of vinyl acetate was added with stirring at 200 rpm, and after the temperature was raised to 60° C., 6.9 g of 5% hydrogen peroxide and 3.0 g of 20% tartaric acid were added for oxidation. Reduce the initiator to initiate emulsion polymerization. After 15 minutes from the start of the polymerization, 226.4 g of vinyl acetate was continuously added over 3 hours, and then 0.9 g of 5% hydrogen peroxide and 0.3 g of 20% tartaric acid were added to terminate the polymerization and obtain a solid content concentration of 49.5 mass % polyvinyl acetate emulsion. In this emulsion, the content ...

Embodiment 2~5

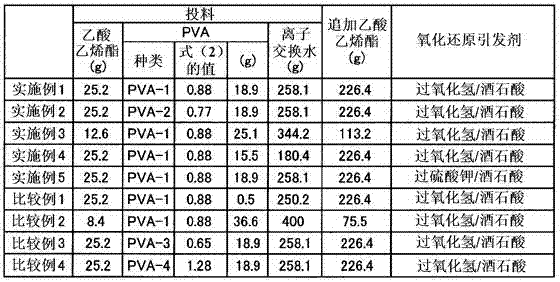

[0172] [Examples 2 to 5 and Comparative Examples 1 to 4]

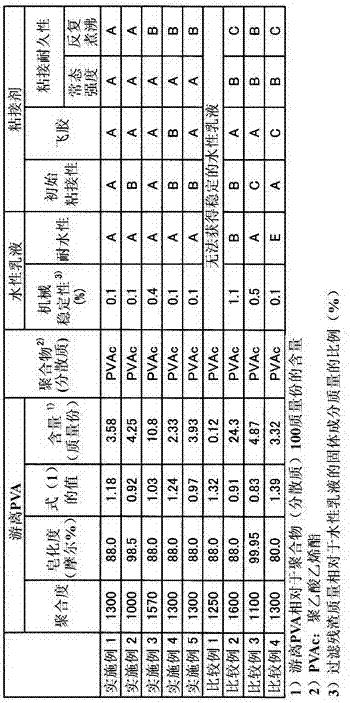

[0173] Except changing feed vinyl acetate, PVA, ion-exchanged water and the kind of addition of vinyl acetate, PVA and initiator when changing emulsion polymerization as shown in Table 1, by the method identical with embodiment 1 Manufacture various water-based emulsions. Table 2 shows the evaluation results of the obtained aqueous emulsions.

[0174] Furthermore, except that various aqueous emulsions produced by the method in Table 1 were used instead of the aqueous emulsion of Example 1, the adhesives of Examples 2 to 5 and Comparative Examples 2 to 4 were produced by the same method as in Example 1. agent. Table 2 shows the physical property evaluation results of the obtained adhesives.

[0175] [Table 1]

[0176]

[0177] [Table 2]

[0178]

[0179] As shown in Table 2, it can be seen that the aqueous emulsions of Examples 1 to 5 are excellent in mechanical stability and coating water resistance. In addit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com