Circular hosiery knitting machines, especially double-cylinder knitting machines, for yarn guides in plated knitting

A technology of knitting machine and yarn guide, which is applied in the directions of knitting, weft knitting, textile and paper making, etc., can solve problems such as reducing productivity and reducing machine operation speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

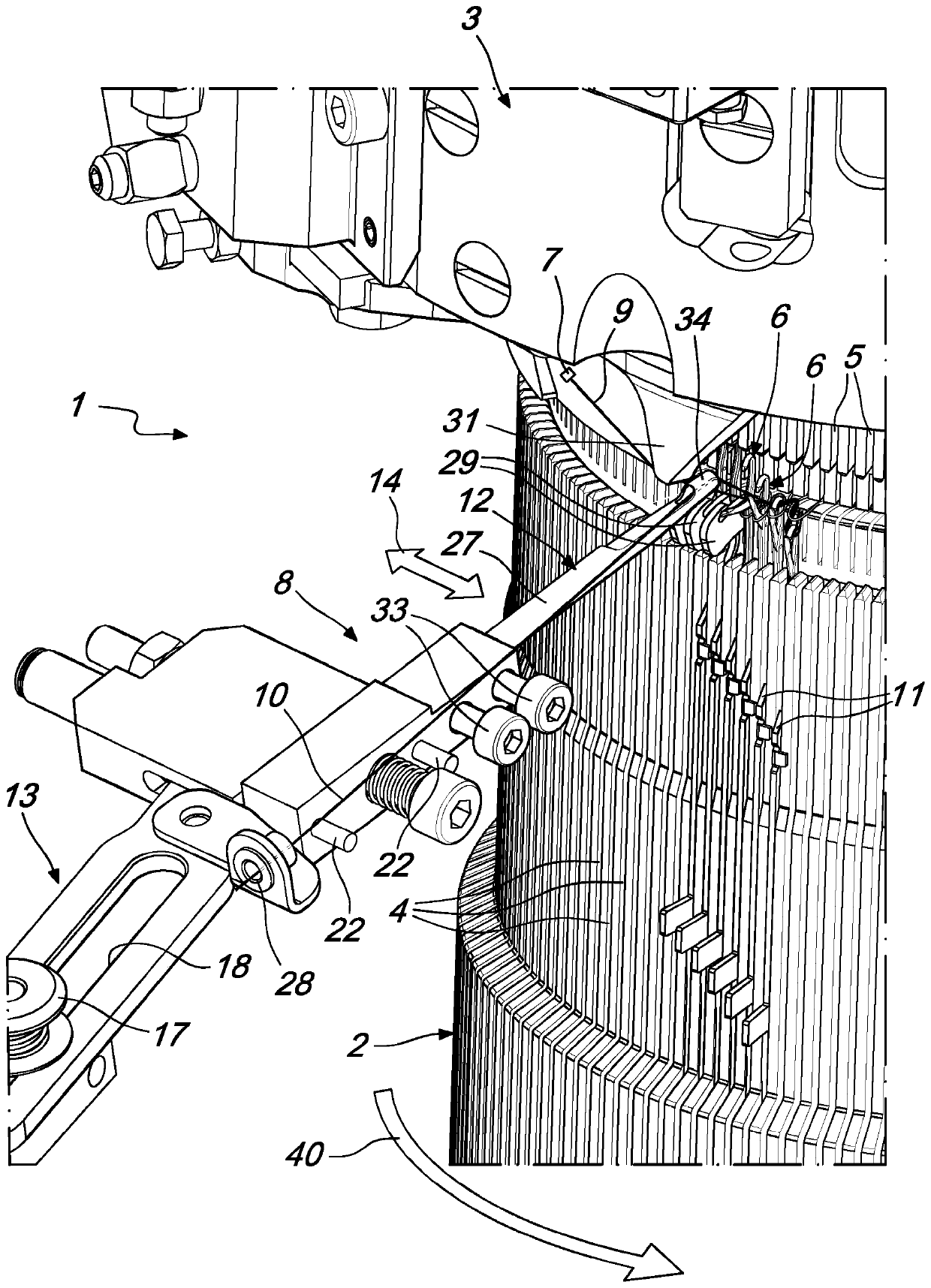

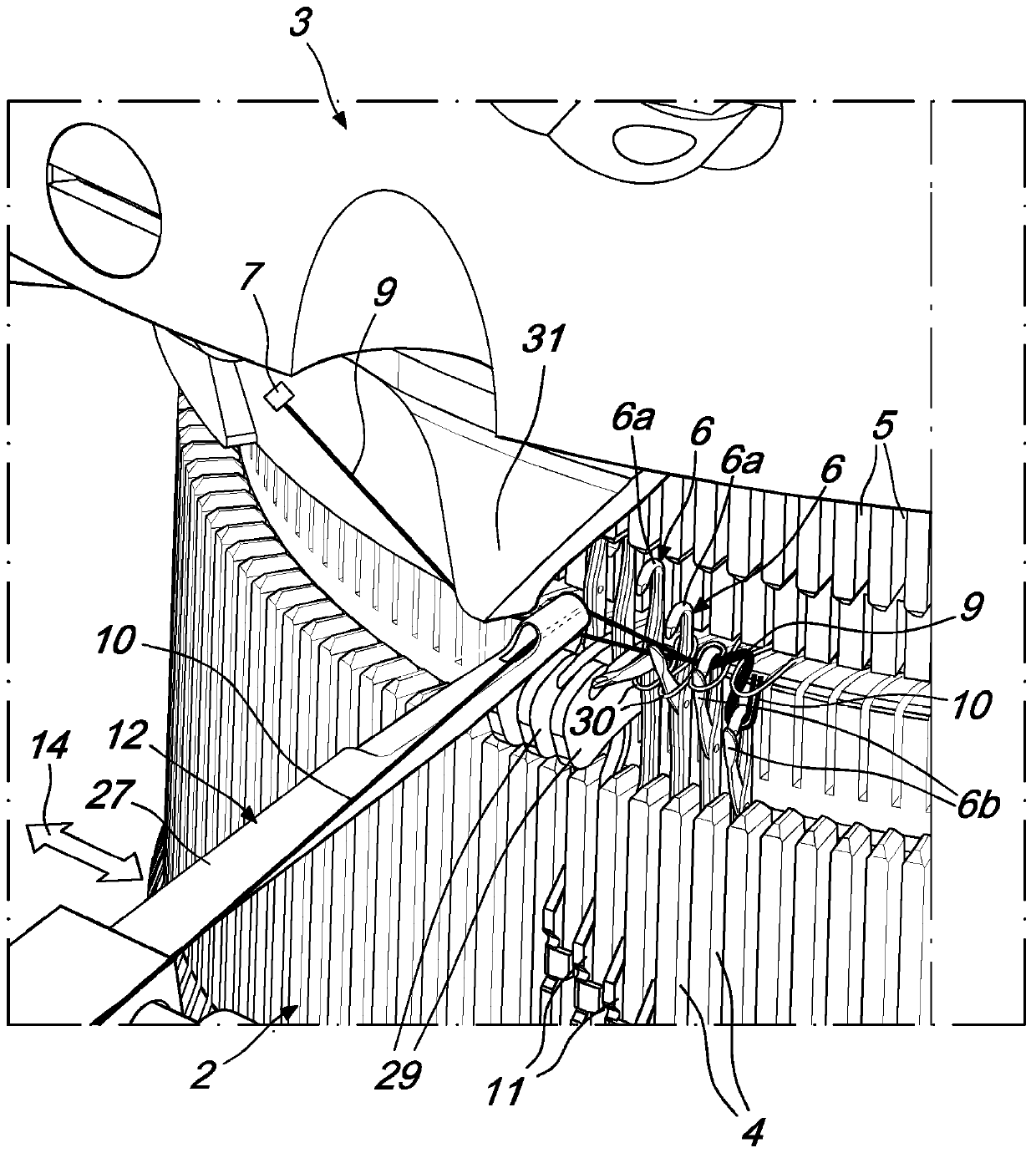

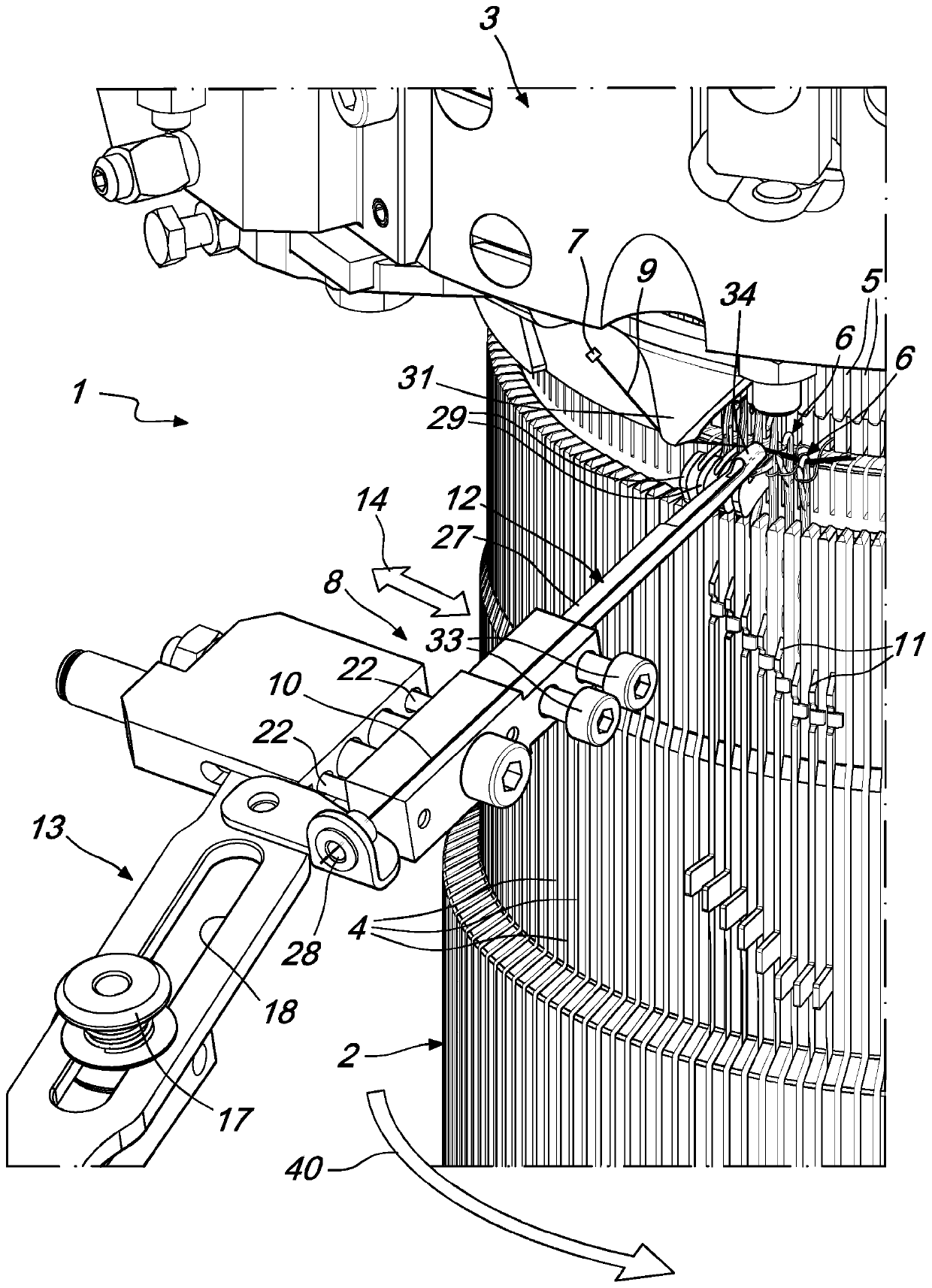

[0027] With reference to the accompanying drawings, a machine according to the invention, indicated generally by the reference numeral 1 and only partially shown for the sake of simplicity, comprises at least one cylinder 2, 3 arranged such that its axis 2a is vertical and in its On the side surface there are a plurality of axial grooves 4 , 5 each receiving a needle 6 . The cylinders 2, 3 are actuatable in a rotational movement about their own axis 2a relative to at least one feed or blank, in which at least two yarn guides 7, 8 are arranged for plating knitting, the yarn guides having The function of supplying the needles 6 of the machine with the yarn required for the production of knitted fabrics.

[0028] The two yarn guides 7, 8 include the distribution of the base yarn 9 through the square figure 1 and figure 2 A first yarn guide 7 of known type schematically shown in , and a second yarn guide 8 for distributing the reinforcing yarn 10 .

[0029] In the embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com