Device for introducing a release agent into a hollow workpiece

A hollow workpiece and release agent technology, applied in metal processing equipment, welding equipment, laser welding equipment, etc., can solve problems such as difficulty, uneconomical application, technical trouble, etc., and achieve the effect of not damaging productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

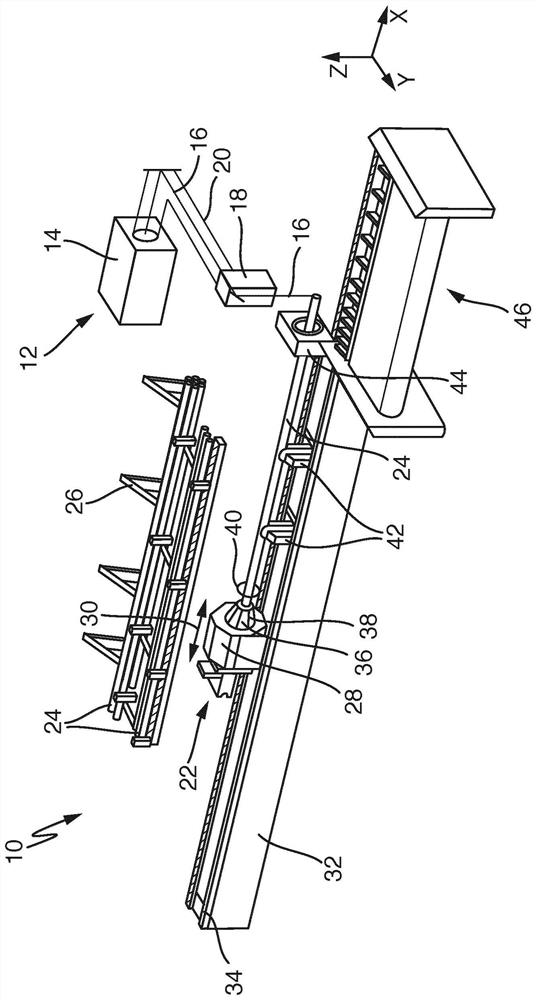

[0043] figure 1 A system for machining hollow workpieces is shown in a schematically simplified form, which is generally designated by the reference numeral 10 .

[0044] The system 10 first includes a laser processing machine 12 . The laser processing machine 12 includes a laser beam source 14 for generating a laser beam 16 , a laser cutting head 18 and a beam guidance device 20 for guiding the laser beam 16 from the laser beam source 14 to the laser cutting head 18 .

[0045] The system 10 also includes a supply device 22 for laterally supplying a workpiece 24 to be processed, in particular cut, by the laser processing machine 12 by means of the generated laser beam 16 . The supply device 22 comprises holding means 28 for holding and moving the workpiece 24 so that the workpiece can be laser cut. The holding device 28 is motor-driven and can move back and forth in a feed direction (X-direction) 30 . The supply device 22 also includes a machine bed 32 with a guide rail 34 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com