Method of forming bank, method of forming film pattern, device, and electronic apparatus

A cofferdam and pattern technology, applied in the direction of instruments, circuits, electrical components, etc., can solve the problems of poor contact holes and inability to form contact holes well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

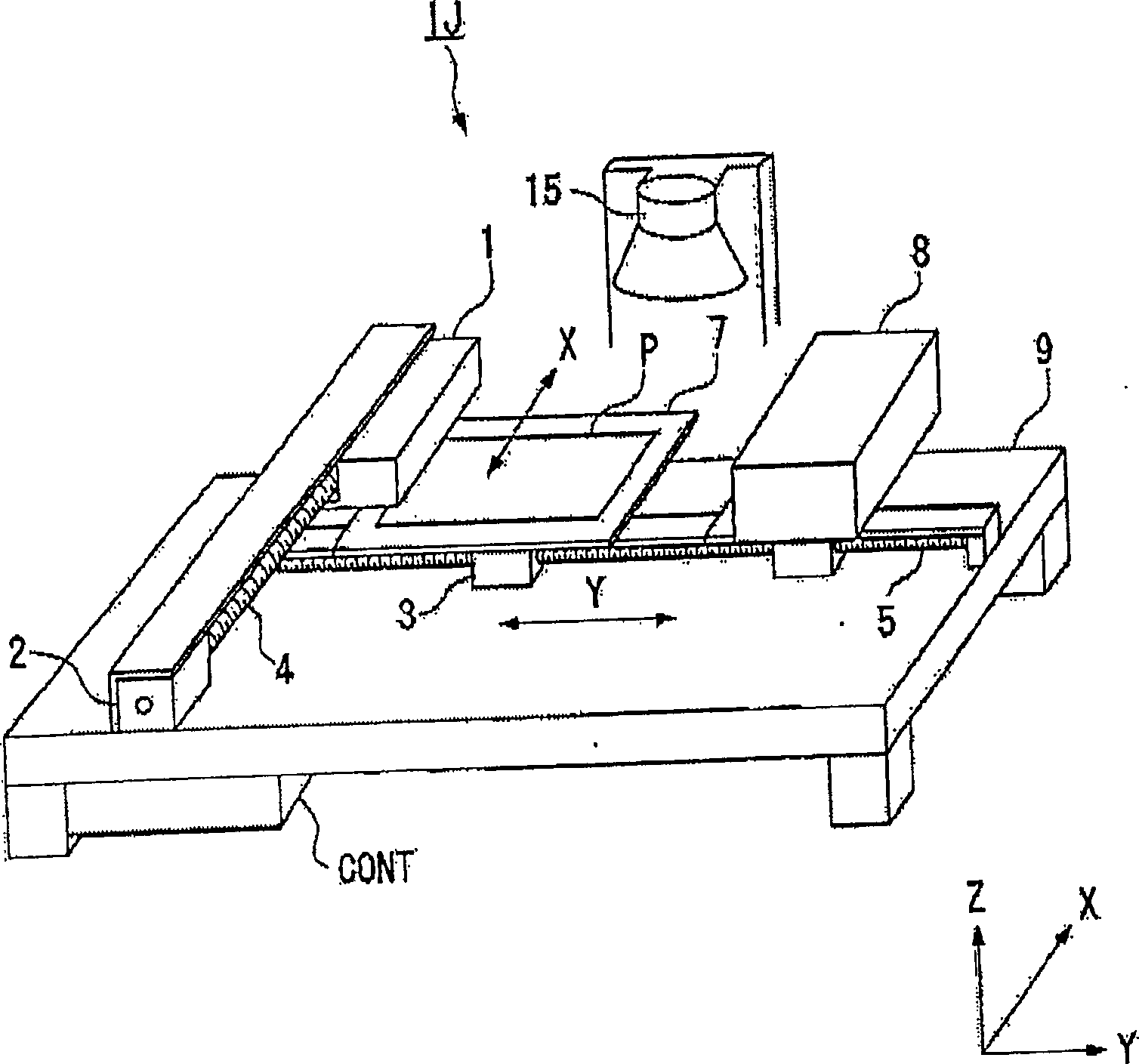

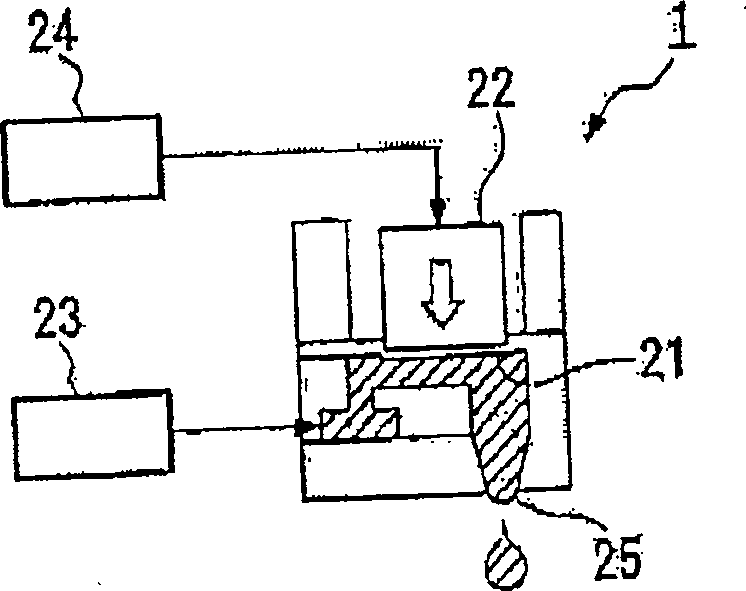

[0057] First, in the film pattern forming method of the present invention, the ink (functional liquid) for wiring patterns (film patterns) containing conductive fine particles is ejected in droplet form from the nozzles of the droplet ejection head by the droplet discharge method, and the corresponding wiring pattern An embodiment in which a wiring pattern (film pattern) is formed in a concave portion of a bank formed on a substrate, that is, in a region partitioned by the bank will be described.

[0058] Here, the wiring pattern ink (functional liquid) is constituted by a dispersion liquid in which conductive fine particles are dispersed in a dispersant. In this embodiment, in addition to metal fine particles containing at least one of gold, silver, copper, aluminum, chromium, manganese, molybdenum, titanium, palladium, tungsten, and nickel as the conductive fine particles, their oxidized particles are also used. substances and conductive polymers or superconductor particles,...

no. 2 Embodiment approach

[0129] Next, another embodiment in the case where the method for forming a film pattern of the present invention is used for a method for forming a wiring pattern (film pattern) will be described.

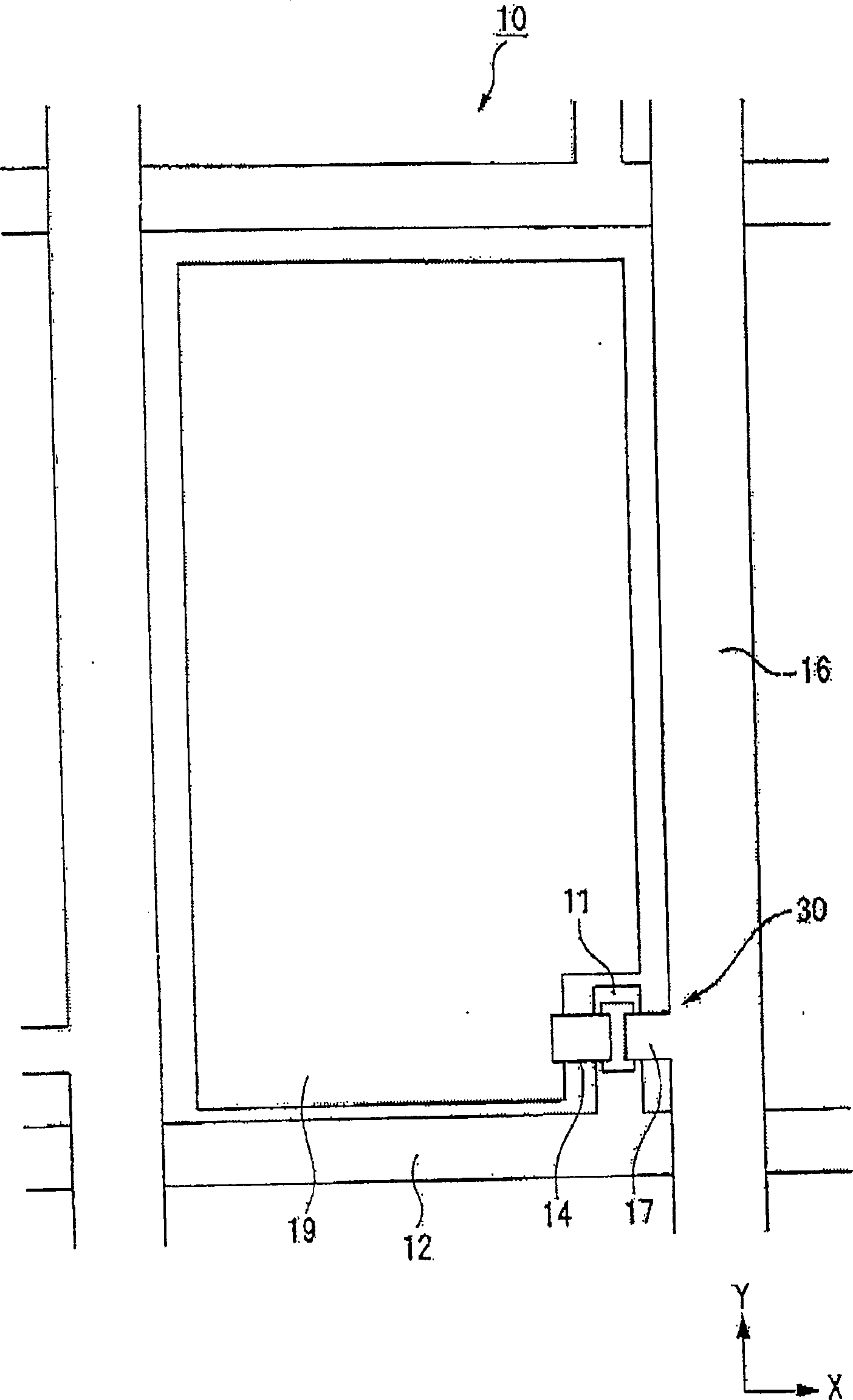

[0130] The difference between this embodiment and the previous embodiments is that Figure 5 The ultraviolet irradiation treatment (ultraviolet irradiation process) shown in (c) and Figure 5 The exposure processing (exposure process) shown in (d) is performed simultaneously.

[0131] That is, in this embodiment, if Figure 5 As shown in (b), the lyophobic treatment is carried out in the cofferdam membrane 31, and after the lyophobic treatment layer 37 is formed on its surface, as Figure 9 As shown, the ultraviolet irradiation treatment and the exposure treatment were simultaneously performed using one mask M. For such processing, for example, the processing device has an exposure light source for irradiating light such as G-line (254nm), H-line (365nm), and I-line (405nm), and...

no. 3 Embodiment approach

[0137] Next, another embodiment of the method for forming a film pattern of the present invention will be described. In this embodiment, circuit wiring (wiring pattern) is further formed on the wiring pattern (film pattern) formed in the previous first or second embodiment. In addition, the droplet discharge method, the droplet discharge device, and the manufactured semiconductor device, etc., used in this embodiment are the same as the droplet discharge method, droplet discharge device, and semiconductor device in the first embodiment. Basically the same.

[0138] In this embodiment, first as Figure 10 As shown in (a), on the gate wiring 12 (gate electrode 11) as a wiring pattern formed in the first or second embodiment, a gate insulating film (insulating film 28) as a semiconductor layer is formed by plasma CVD. Active layer 63 and bonding layer 64 are successively formed. The silicon nitride film as the insulating film 28 , the amorphous silicon film as the active layer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com