Fuel injection valve

A fuel injection valve, fuel injection technology, applied in the direction of fuel injection device, charging system, engine components, etc., to achieve the effect of easy design change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

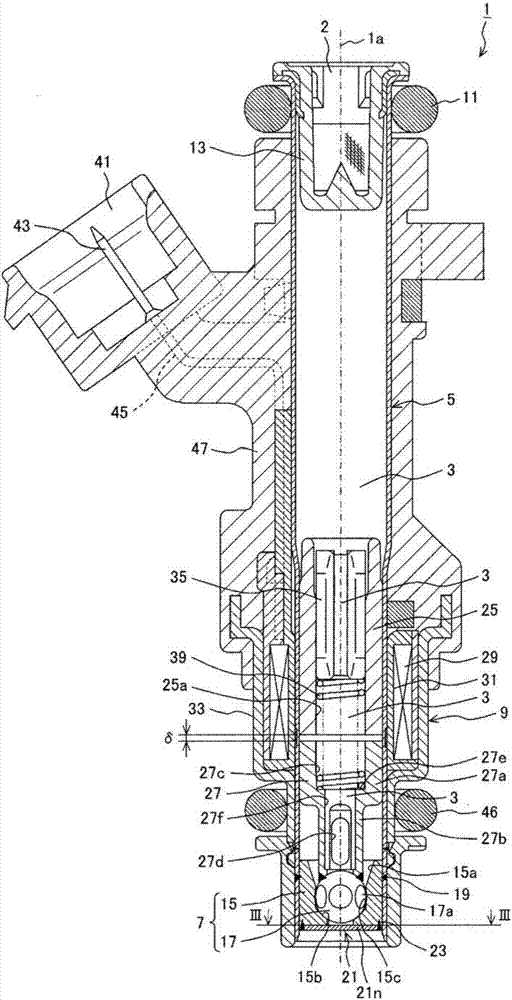

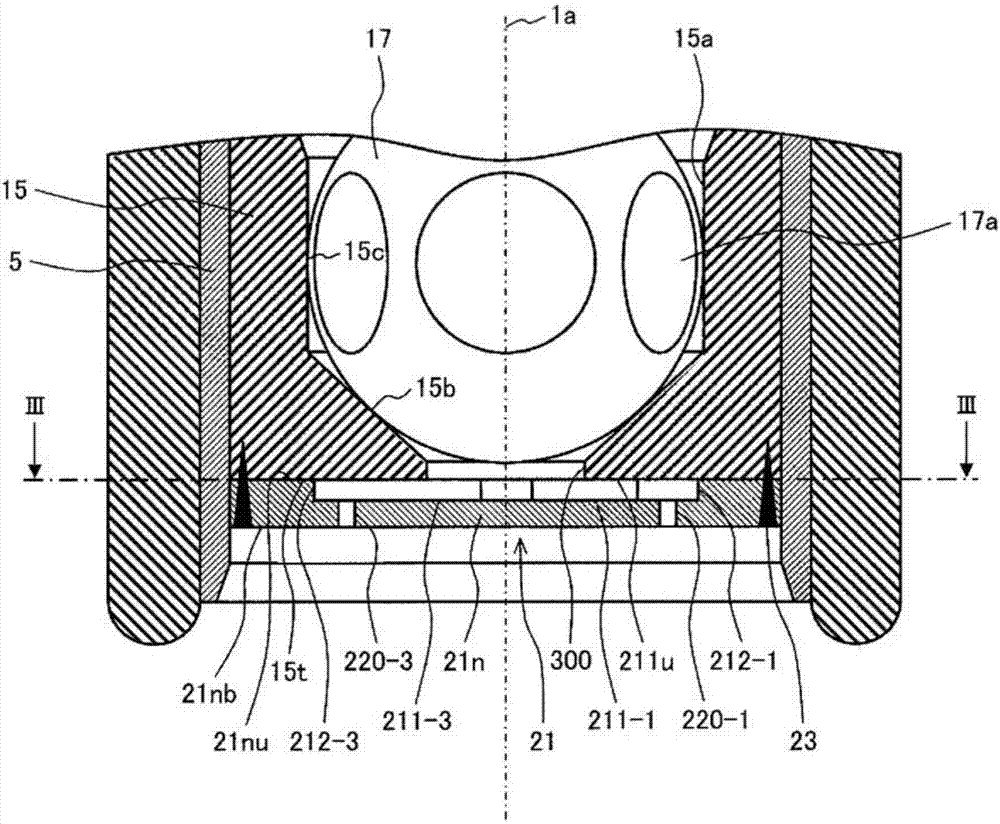

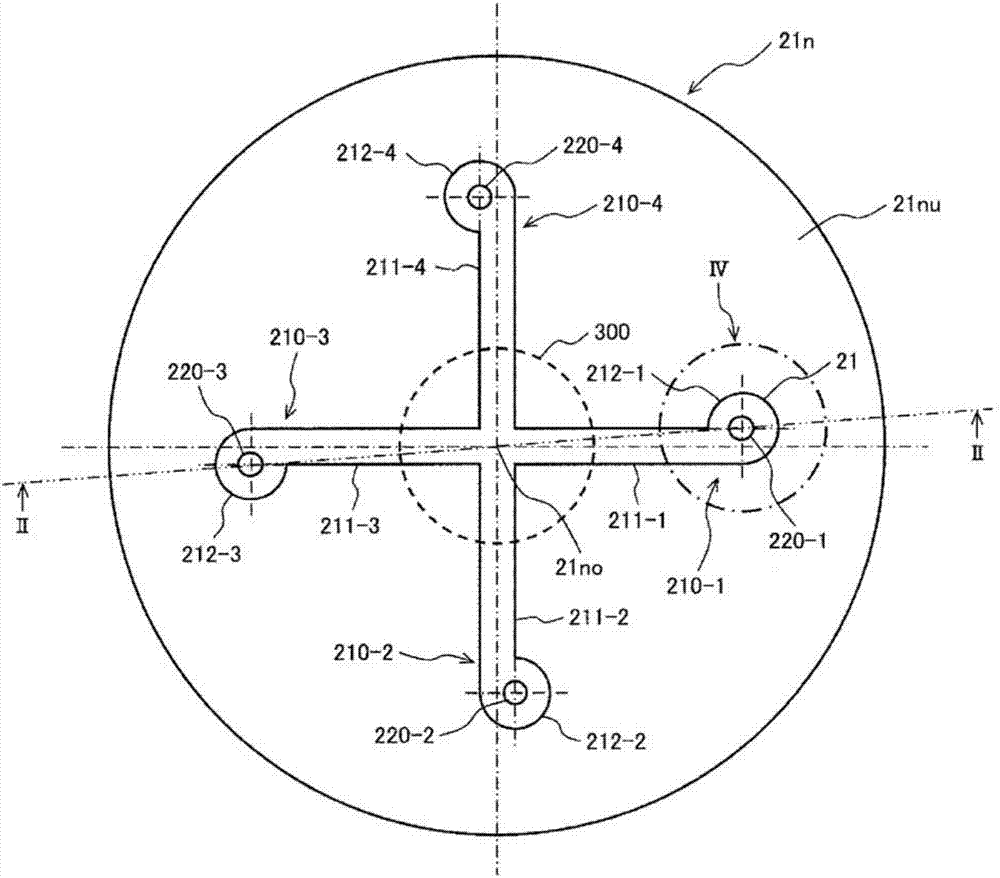

[0031] In the present embodiment, the valve portion 7 including the valve seat member 15 and the valve body 17 and the nozzle plate 21 n constitute a nozzle portion for injecting fuel. A nozzle plate 21n forming a fuel injection hole 220 and a swivel passage 210 (lateral passage 211 and swivel chamber 212 ) to be described later is joined to the front end surface of the nozzle body (valve seat member 15 ) constituting the valve portion 7 .

[0032] A drive unit 9 for driving the valve body 17 is disposed in the middle of the cylindrical body 5 . The driving unit 9 is constituted by an electromagnetic actuator. Specifically, the driving unit 9 is constituted by a fixed iron core 25 , a movable element (movable member) 27 , an electromagnetic coil 29 , and a yoke 33 .

[0033] The fixed core 25 is made of a magnetic metal material, and is press-fitted and fixed to the inner side of the middle portion in the longitudinal direction of the cylindrical body 5 . The fixed core 25 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com