Optical object, optical-film laminate, and process for producing optical object

A manufacturing method and technology for an optical body, applied in the field of optical bodies, can solve the problems of insufficient protection of concave-convex structure, deterioration of anti-reflection film performance, detachment of protective film, etc., and achieve the effects of suppressing light reflection, suppressing defects, and improving operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

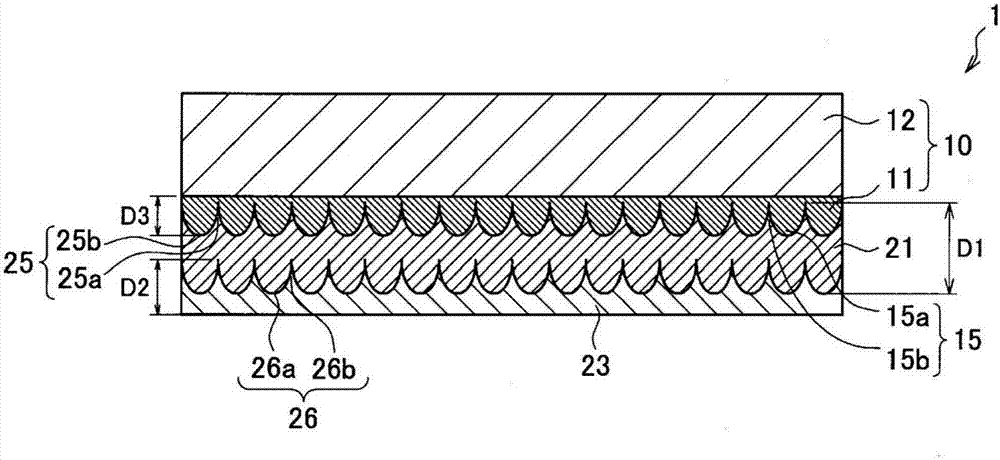

[0187] In Example 1, the optical body 1 was produced according to the following process. A PET film with a thickness of 50 μm was prepared as the base film 12 . In addition, an ultraviolet-curable acrylic resin (Dexerials Co., Ltd., SK1100 series) to which a silicone-based mold release agent (BYK company, silicone lubricant BYK333) was added was prepared as a photocurable resin. Then, the uncured resin layer 11p for main films is formed on the base film 12 by apply|coating photocurable resin on the base film 12. In addition, the first master disk 30 is fabricated using the exposure apparatus 200 described above. Then, by pressing the circumferential surface of the first original disc 30 to the main film uncured resin layer 11p, the fourth concave-convex structure 32 formed on the circumferential surface of the first master disc 30 is transferred to the main film uncured resin layer. 11p. Then, by curing the uncured resin layer 11p for the main film, the concave-convex resin...

Embodiment 2

[0201] Except that the refractive index of the adhesive layer 23 was 1.7 and the refractive index of the adherend 502 was 1.7, the same process as in Example 1 was performed to calculate the spectral reflection spectrum of the optical film bonded body. The results are shown in Table 7B. Also in Example 2, almost the same results as in Example 1 were obtained.

Embodiment 3

[0207] Except having made the refractive index of the adhesive bond layer 23 1.75, and the refractive index of the to-be-adhered body 502 were 1.75, the same process as Example 1 was performed, and the spectral reflection spectrum of the optical film bonded body was calculated. The results are shown in Table 7C. Also in Example 3, almost the same results as in Example 1 were obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com