Jetting device used for generating liquid drops in low-viscosity liquid space environment

A liquid space and droplet generation technology, applied in the direction of liquid injection device, injection device, injection device, etc., can solve the problem that uniform droplets with large particle size cannot be sprayed, and achieve high reliability, avoid output attenuation, and stimulate small energy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

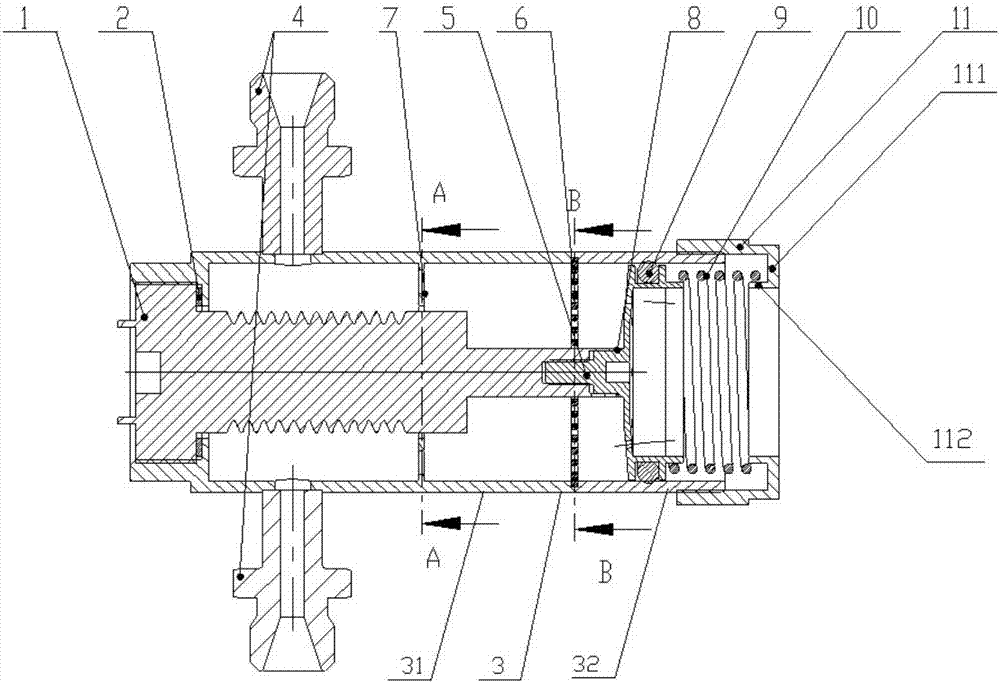

[0034] Embodiment one: if figure 1 , the injection device used for the generation of droplets in the low-viscosity liquid space environment includes a front housing 32, a rear housing 31, a piezoelectric ceramic actuator 1, a nozzle 5, a rubber sealing ring 9, a rectifying plate 6, and a positioning rectifying plate 7, Spring 10, top cover 11, adapter 4; piezoelectric ceramic actuator 1 adopts a high-voltage mechanical packaging form of multi-layer piezoelectric ceramic stacking, the middle section of the outer wall of the body is bellows-shaped, and the two ends are straight tube-shaped; positioning rectifier plate 7 is integrated with the rear housing 31, located upstream of the rectifying plate 6, the piezoelectric ceramic actuator passes through the center hole of the positioning rectifying plate 7, the front housing 32 and the rear housing 31 are welded end to end to form the housing 3, and the rectifying plate 6 is clamped at the connection end surface of the front housi...

Embodiment 2

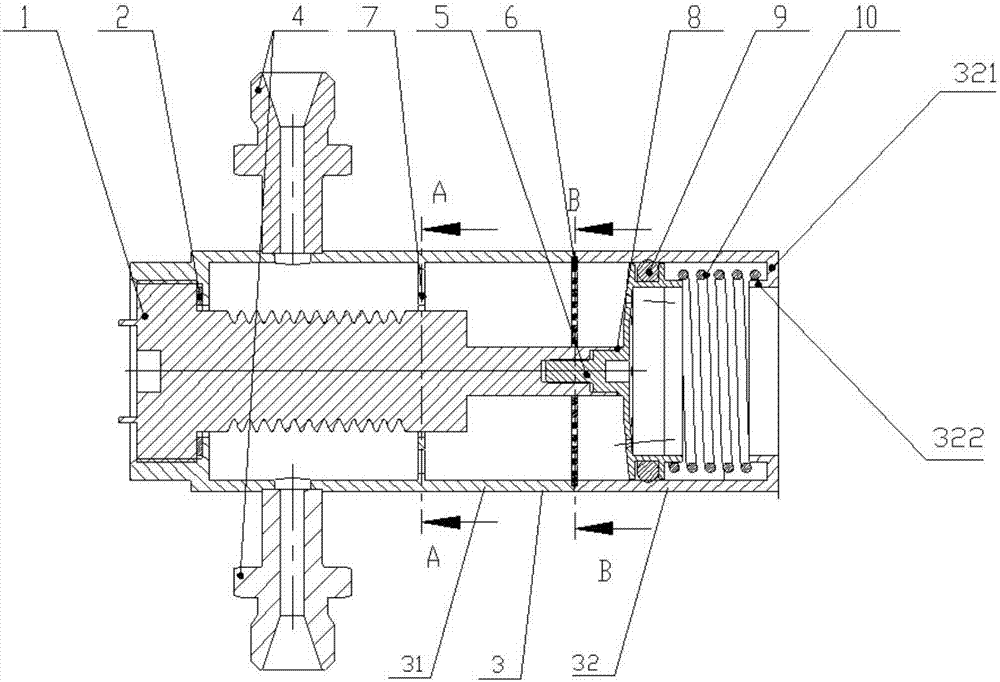

[0037] Embodiment two: if figure 2 As shown, the injection device for the generation of droplets in the low-viscosity liquid space environment includes a front housing 32, a rear housing 31, a piezoelectric ceramic actuator 1, a nozzle 5, a rubber sealing ring 9, a rectifying plate 6, and a positioning rectifying plate 7. Spring 10, adapter 4; piezoelectric ceramic actuator 1 adopts a high-voltage mechanical packaging form of multi-layer piezoelectric ceramic stacking, the middle section of the outer wall of the body is bellows-shaped, and the two ends are straight tube-shaped; positioning rectifier plate 7 and The rear housing 31 is one piece, located upstream of the rectifying plate 6, the piezoelectric ceramic actuator passes through the center hole of the positioning rectifying plate 7, the front housing 32 and the rear housing 31 are welded end to end to form the housing 3, and the rectifying plate 6 is clamped Connected to the connection section of the front housing 32 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com