Dust removing and weighing mechanism of logistics conveying line

A weighing mechanism and conveying line technology, applied in the field of weighing mechanism, logistics conveying line dust removal, can solve the problems of unfavorable precise control, high strength, dust adsorption and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

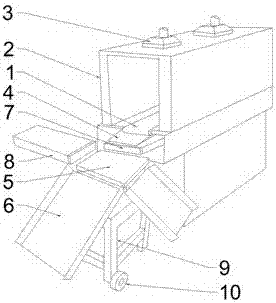

[0010] Below in conjunction with all accompanying drawings the present invention will be further described, and preferred embodiment of the present invention is: see appended figure 1 The dust removal and weighing mechanism of the logistics conveying line described in this embodiment includes a conveyor belt 1, the two sides and the top of the conveyor belt 1 are sealed by stainless steel panels to form a dust removal box 2, and there are several dust removal ports on the top of the dust removal box 2, each A dust collection hood 3 is installed on each dust removal port, and the dust collection cover 3 is in the shape of a trapezoid with a large bottom and a small top. Main pipe connection; under the output end of the conveyor belt 1, there is a guide plate 4 installed obliquely, under the lower end of the guide plate 4, there is a weighing pan 5, and the two sides of the weighing pan 5 are equipped with material distribution guide grooves 6, which are connected with the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com