A Machining Method of Complicated Curved Surface of Brittle Material

A technology for brittle materials and complex curved surfaces, applied in stone processing equipment, fine working devices, manufacturing tools, etc., can solve problems such as low processing efficiency, easy embedding of abrasives, and failure of optical functions, so as to improve the quality of processed surfaces and reduce tool damage. Abrasion, reduced difficulty effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

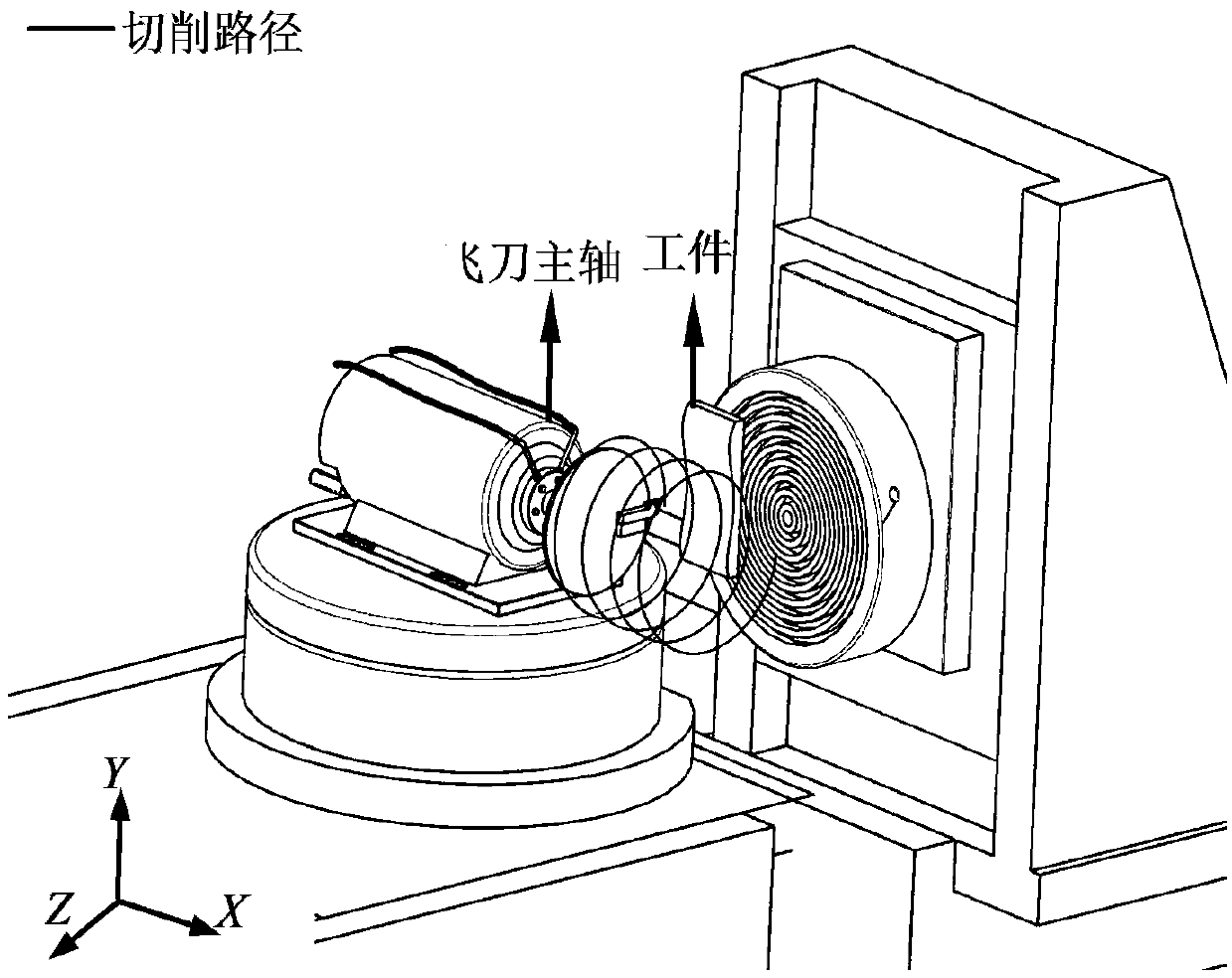

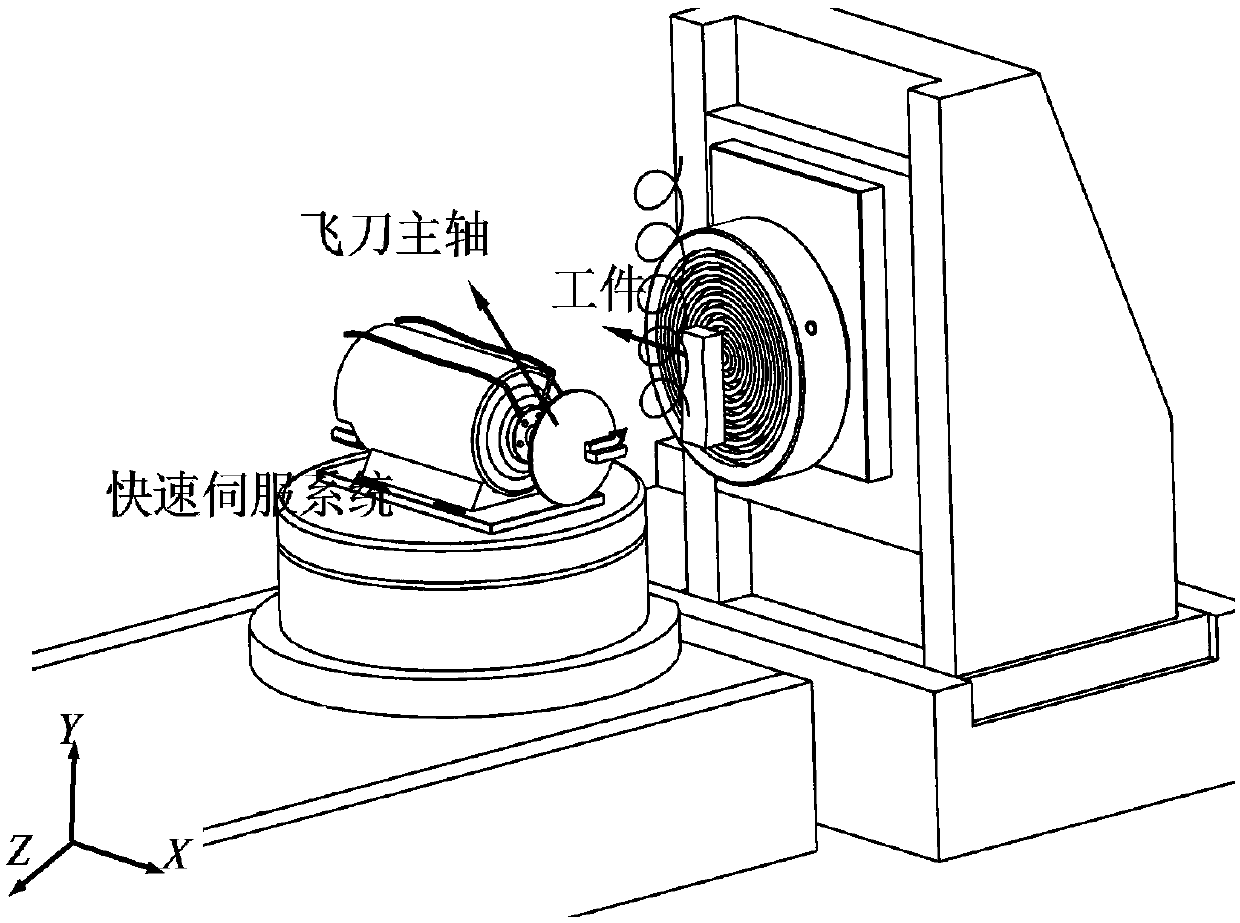

[0025] 1. Build a processing system combining milling and flying tools;

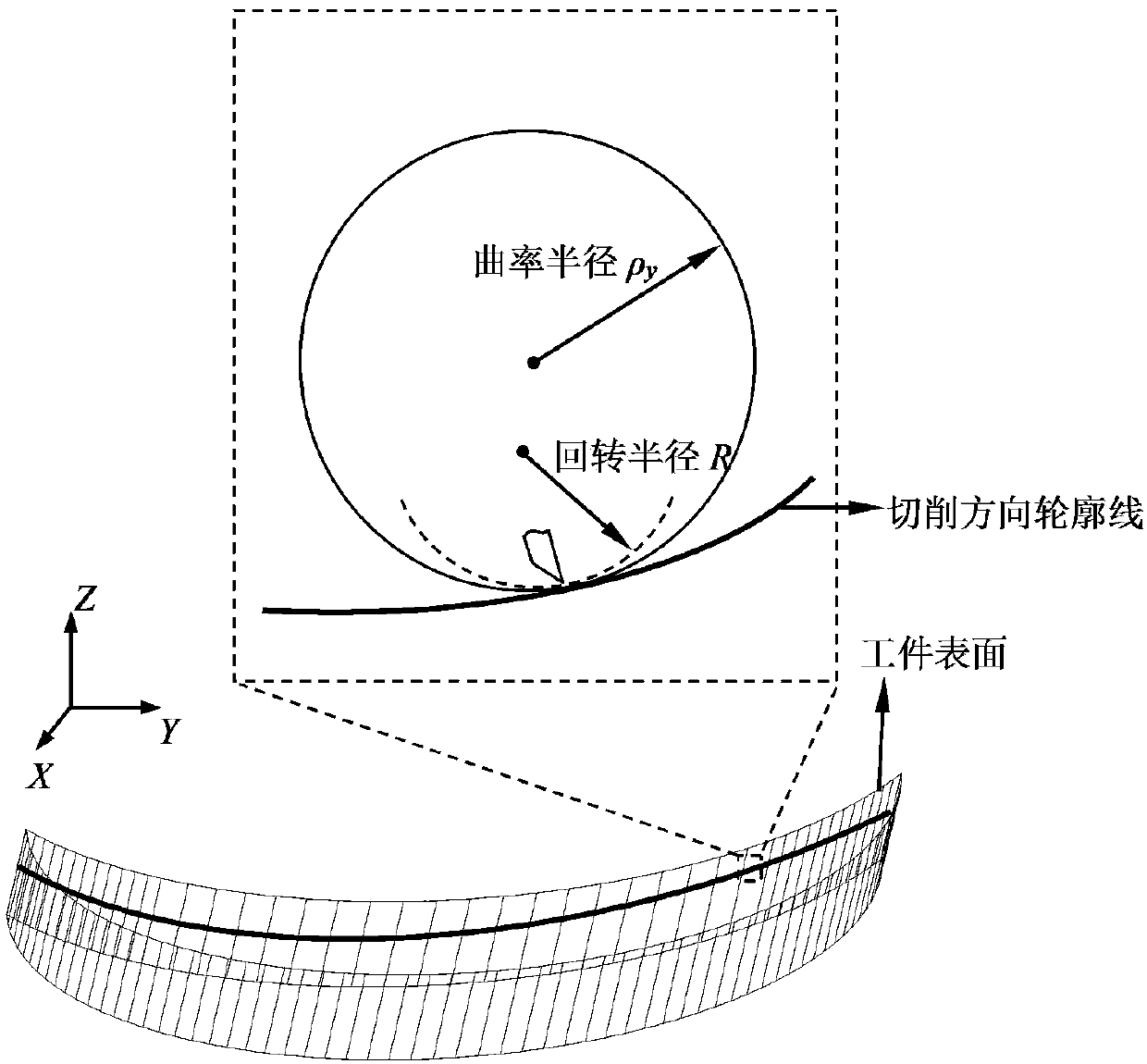

[0026] 2. Select the appropriate radius of rotation of the flying tool spindle and the appropriate milling feed direction to avoid the corresponding radius of curvature being smaller than the radius of rotation of the flying tool, that is, select the appropriate milling spindle speed, feed rate and radius of rotation of the flying tool installation to avoid flying The radius of gyration of the tool is greater than the maximum radius of curvature on any one of its curved surfaces along the linear motion direction of the milling axis.

[0027] 3. According to the characteristics of the processing process and the cutting performance of the material, design suitable cutting parameters and tool geometry parameters; according to the embodiment, select the flying knife spindle speed to be 4000rpm, the radius of gyration to be about 30mm, and the nose radius to be 0.5mm. The directional feed is F=2mm / min, and wh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com