Fan housing for engine cooling module and control method of fan housing

An engine cooling and cooling fan technology, which is applied in the direction of engine cooling, coolant flow control, engine components, etc., can solve the problem of uncontrollable opening time and opening size of the grille, the opening area of the fan cover cannot be changed, and the cooling can not be satisfied. Air flow requirements and other issues to achieve the effect of delaying intervention work time, improving NVH performance, and reducing rotational speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

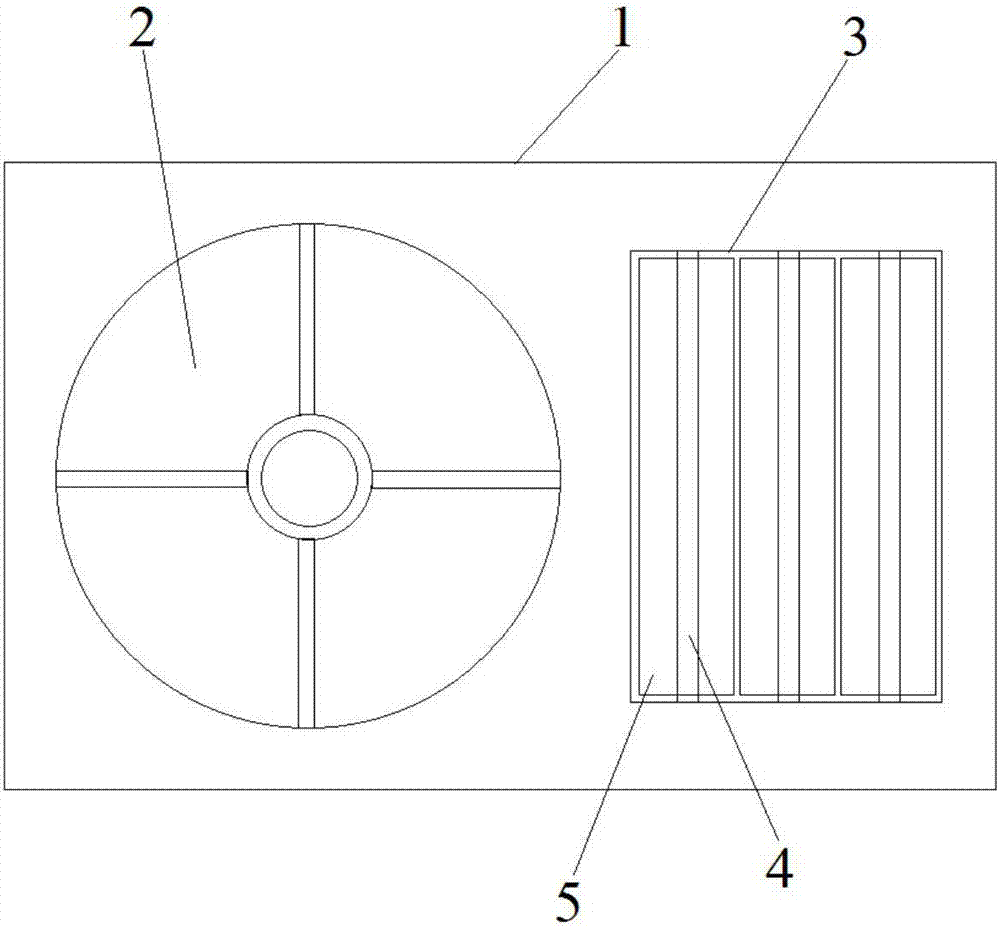

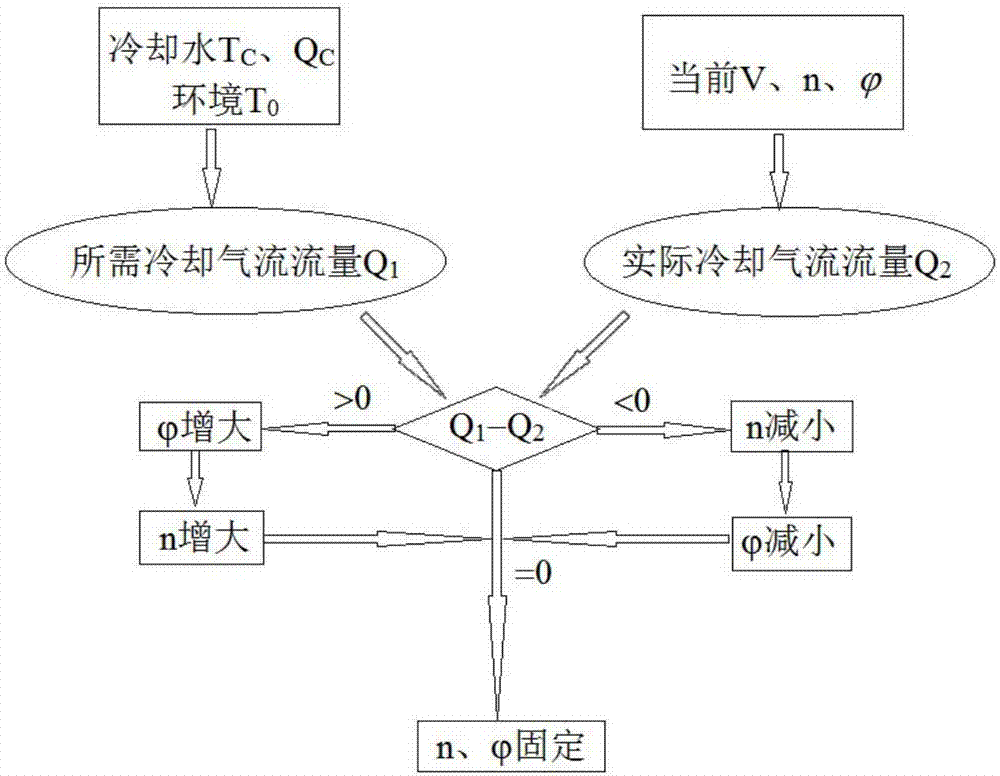

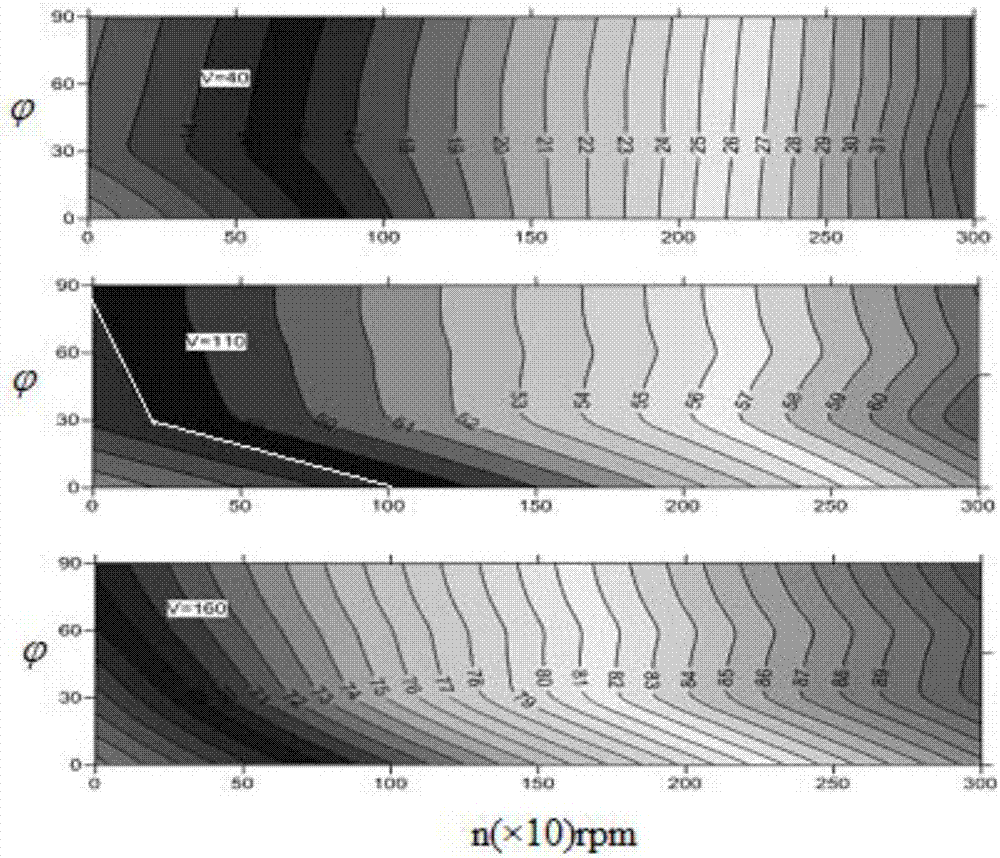

[0035] Such as figure 1 Shown is a fan cover for the engine cooling module, the fan cover is located between the cooling fan and the radiator, the fan cover includes a fan cover main body 1, a cooling fan that is set on the fan cover main body 1 and is adapted to the cooling fan The fan vent 2, the grille vent 3 provided on the main body of the fan cover 1 and the controller, the grille vent 3 are arranged side by side with three active grille assemblies electrically connected to the controller respectively, and the controller passes through the active grille The grill assembly controls the opening size of the grill vents 3 .

[0036] Wherein, the active grille assembly is a louver-type structure, and the active grille assembly includes a rotating shaft 4 arranged in the grille vent 3, a grille plate 5 arranged on the rotating shaft 4, and a rotating shaft stepping motor connected to the rotating shaft 4 , the rotating shaft stepping motor is electrically connected with the c...

Embodiment 2

[0049] In this embodiment, two active grill components are arranged side by side in the grille vent 3 and are respectively electrically connected to the controller. The length of the grille vent 3 is 300 mm, and the width is 110 mm.

Embodiment 3

[0051] In this embodiment, five active grill components are arranged side by side in the grille vent 3 and are respectively electrically connected to the controller. The length of the grille vent 3 is 310mm, and the width is 90mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com