Motor tricycle, transmission system and multifunctional engine with speed reduction and torque increasing functions

A deceleration and torque increase, multi-functional technology, applied in the direction of gear transmission, machine/engine, wheel transmission, etc., can solve the problem that the performance cannot meet the existing demand, the engine case is easily damaged, and the engine performance is easily affected. , to achieve the effect of low cost, easy failure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

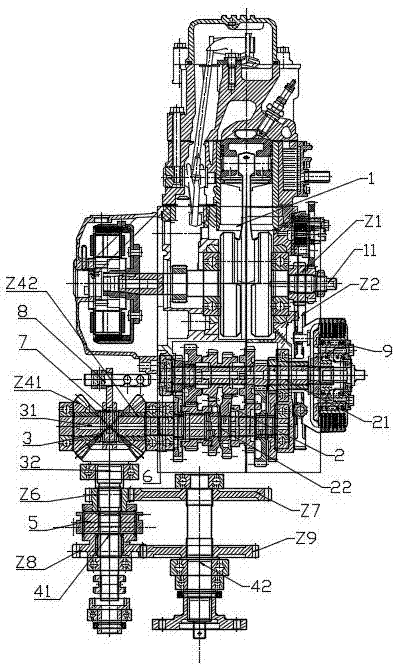

[0032] Embodiment 1: as figure 1 and figure 2 As shown, a multifunctional engine with deceleration and torque increase includes a heat engine 1 connected in sequence, a built-in speed change mechanism 2, a built-in reversing mechanism 3 and a built-in deceleration and torque increase mechanism 4, that is, the output end of the heat engine 1 is connected to the The input end of the built-in speed change mechanism 2 is connected, the output end of the built-in speed change mechanism 2 is connected with the input end of the described built-in reversing mechanism 3, the output end of the described built-in reversing mechanism 3 is connected with the input of the deceleration and torque increasing 4 end connection.

[0033] Wherein, the built-in deceleration and torque increasing mechanism 4 includes an input shaft 41 and an output shaft 42 arranged in parallel, and at least two sets of deceleration and torque increasing gear pairs are arranged between the input shaft 41 and the ...

Embodiment 2

[0043] Embodiment 2: as figure 1 As shown, a multifunctional engine with deceleration and torque increase includes a heat engine 1 connected in sequence, a built-in speed change mechanism 2, a built-in reversing mechanism 3 and a built-in deceleration and torque increase mechanism 4, that is, the output end of the heat engine 1 is connected to the The input end of the built-in speed change mechanism 2 is connected, the output end of the built-in speed change mechanism 2 is connected with the input end of the described built-in reversing mechanism 3, the output end of the described built-in reversing mechanism 3 is connected with the input of the deceleration and torque increasing 4 end connection.

[0044] Specifically: the heat engine 1 and the built-in speed change mechanism 2 are vertically arranged, and the main shaft 21 and the auxiliary shaft 22 of the built-in speed change mechanism 2 are parallel to the crankshaft 11 of the heat engine 1, and the input of the main shaf...

Embodiment 3

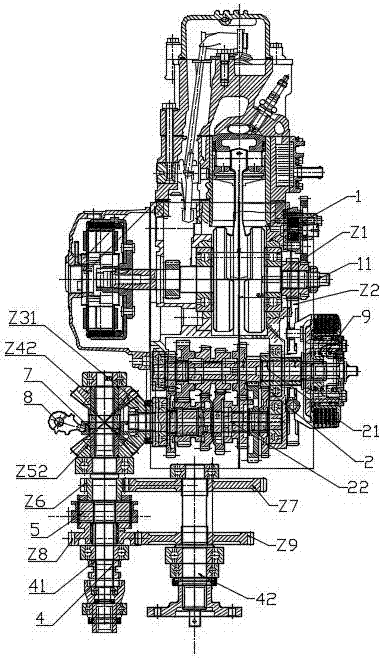

[0058] Embodiment 3: as figure 2 As shown, a multifunctional engine with deceleration and torque increase includes a heat engine 1 connected in sequence, a built-in speed change mechanism 2, a built-in reversing mechanism 3 and a built-in deceleration and torque increase mechanism 4, that is, the output end of the heat engine 1 is connected to the The input end of the built-in speed change mechanism 2 is connected, the output end of the built-in speed change mechanism 2 is connected with the input end of the described built-in reversing mechanism 3, the output end of the described built-in reversing mechanism 3 is connected with the input of the deceleration and torque increasing 4 end connection.

[0059] Specifically: the heat engine 1 and the built-in speed change mechanism 2 are vertically arranged, and the main shaft 21 and the auxiliary shaft 22 of the built-in speed change mechanism 2 are parallel to the crankshaft 11 of the heat engine 1, and the input of the main sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com