A special burner for high temperature biomass gas

A biomass gas and burner technology, applied in gas fuel burners, burners, combustion methods, etc., can solve problems such as extinguishing, environmental pollution, heat loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

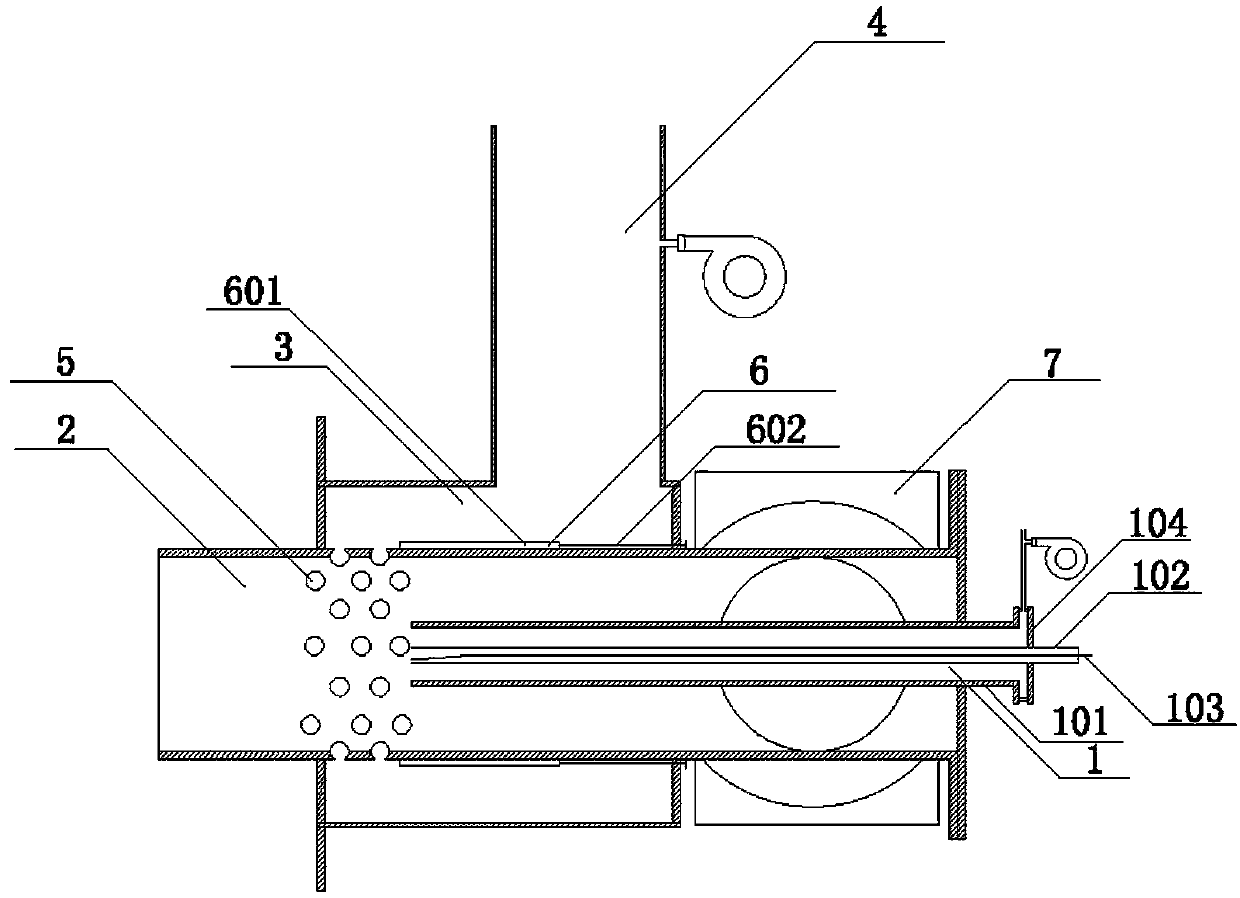

[0012] Such as figure 1 A special burner for high-temperature biomass gas, including a first pipeline 1 arranged horizontally, the first pipeline 1 includes two layers, the outer layer is a first combustion-supporting agent pipeline 101, the first combustion-supporting agent is air, and the inner layer is Gas pipeline 102, the first gas is liquefied gas, there is a gap between the outer layer and the inner layer for the first combustion accelerant to pass through, and an electronic pulse ignition device 103 is arranged inside the gas pipeline 102, and the electronic pulse ignition device 103 includes a high-voltage package and a firing pin, the right end of the first pipeline 1 is an air inlet, and the left end is an air outlet, the air inlet of the gas pipeline 102 is connected with the liquefied gas tank, and a pressure limiting device is provided between the air inlet and the liquefied gas tank Valve, the air inlet of the first combustion aid pipeline 101 is fixedly connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com