Free piston device and method for operating a free piston device

A piston and free technology, applied in the direction of free piston engine, internal combustion piston engine, reciprocating piston engine, etc., can solve the problems of unsuitable external source ignition operation, etc., and achieve the effect of increased turbulent flame speed, fast conversion and low emission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

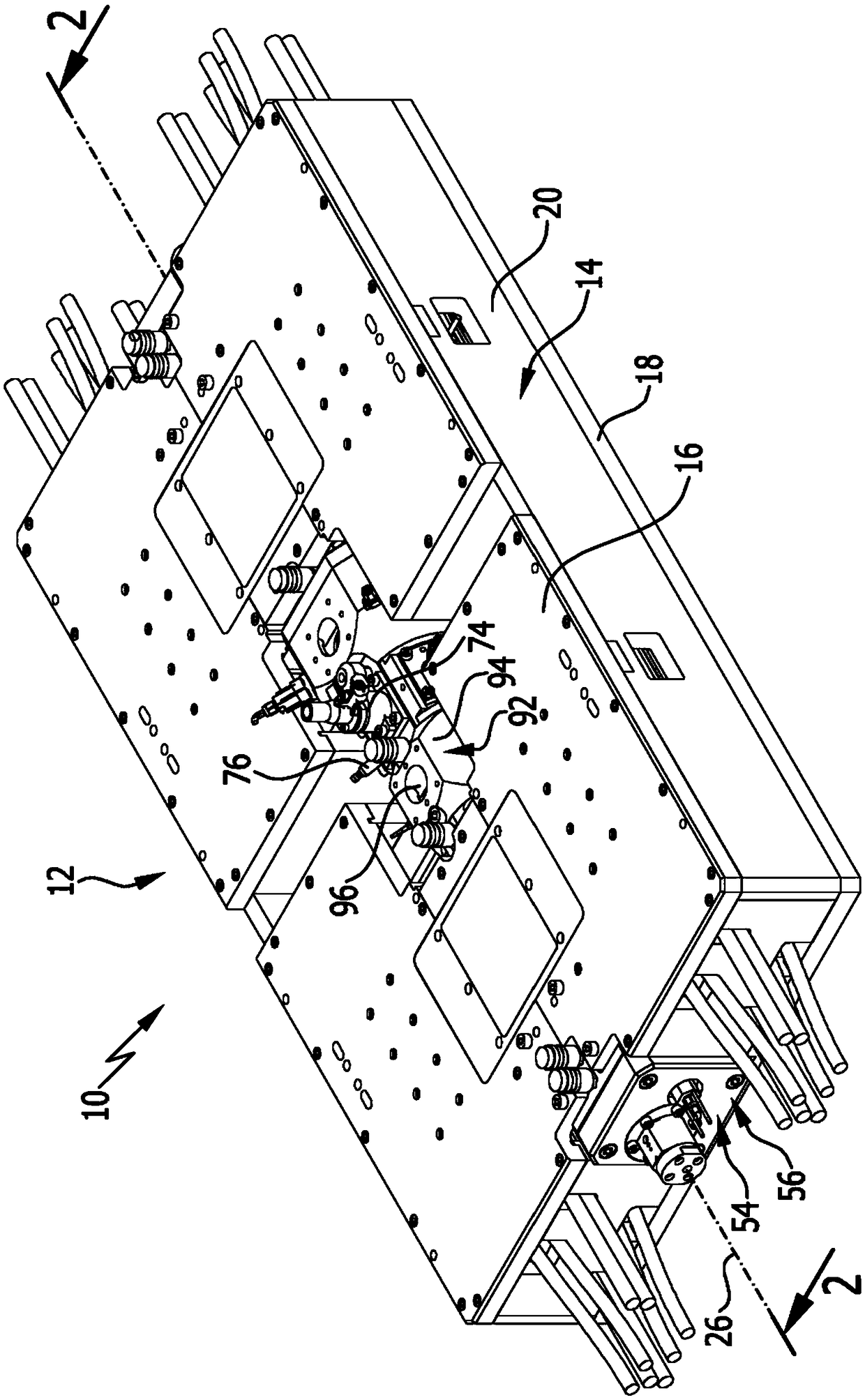

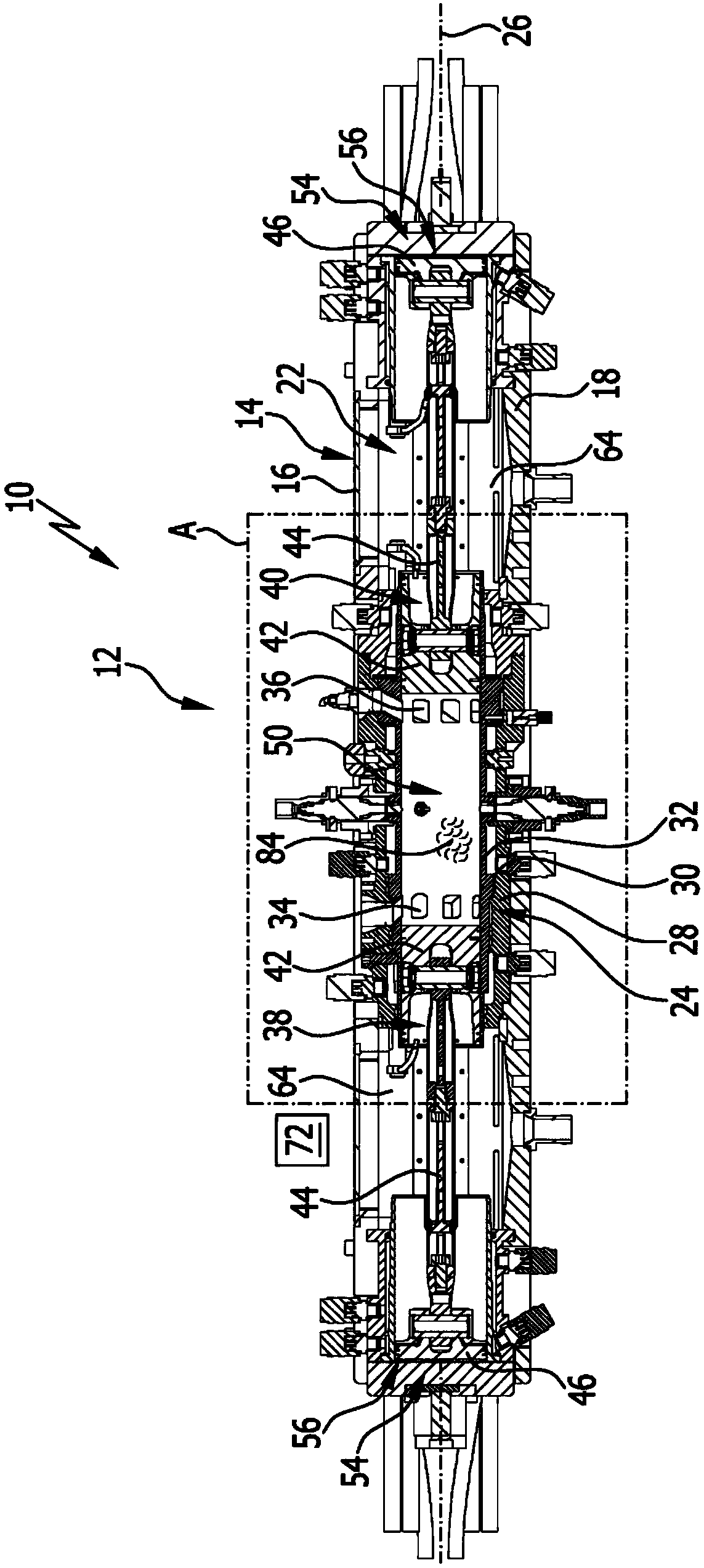

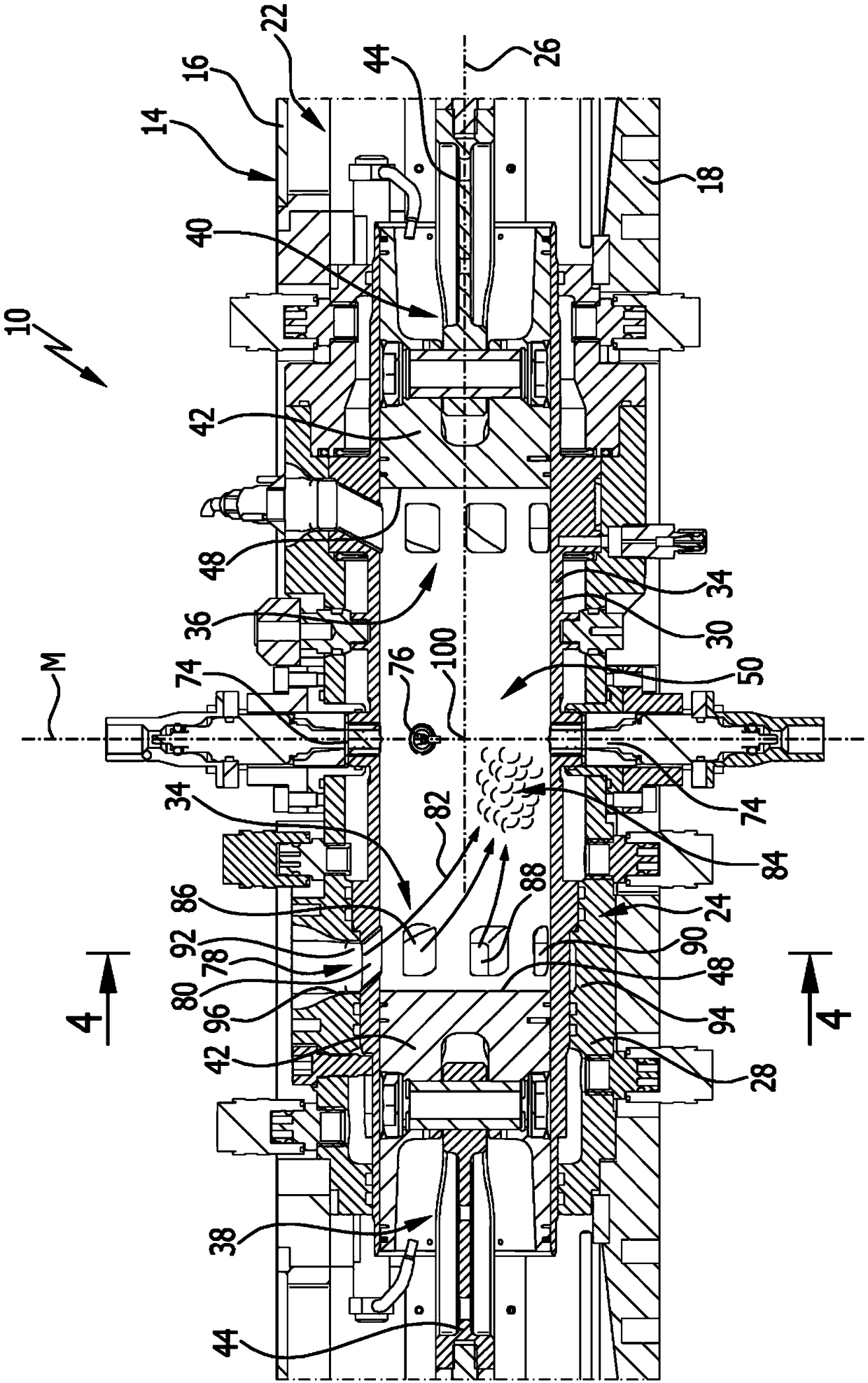

[0054] The drawing shows a preferred embodiment of the free-piston device according to the invention, referenced 10 , which in particular forms a free-piston motor 12 .

[0055] The free piston device 10 comprises an outer housing 14 , which here is cuboid and designed as a flat shell. The housing 14 defines a receiving space 22 between the top wall 16 , the bottom wall 18 and the side walls 20 .

[0056] A piston chamber 24 is arranged in the housing 14 . The piston cavity 24 extends longitudinally and defines an axis 26 of the free piston device 10 . The piston chamber 24 has a housing 28 divided into separate parts, which is approximately in the shape of a hollow cylinder. A piston bushing 30 of the piston chamber 24 is arranged in the housing 28 . Piston bushing 30 becomes hollow cylinder shape substantially, and inserts the middle section of housing 28 ( Figures 2 to 4 ).

[0057] An opening is provided on the inner wall 32 of the piston bushing 30 and thus forms th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com