A gear state monitoring index extraction method based on a discrete random separation algorithm

A discrete random, extraction method technology, applied in the direction of machine gear/transmission mechanism testing, mechanical component testing, machine/structural component testing, etc., to achieve the effect of state monitoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments. This embodiment adopts primary fatigue life data of the axle.

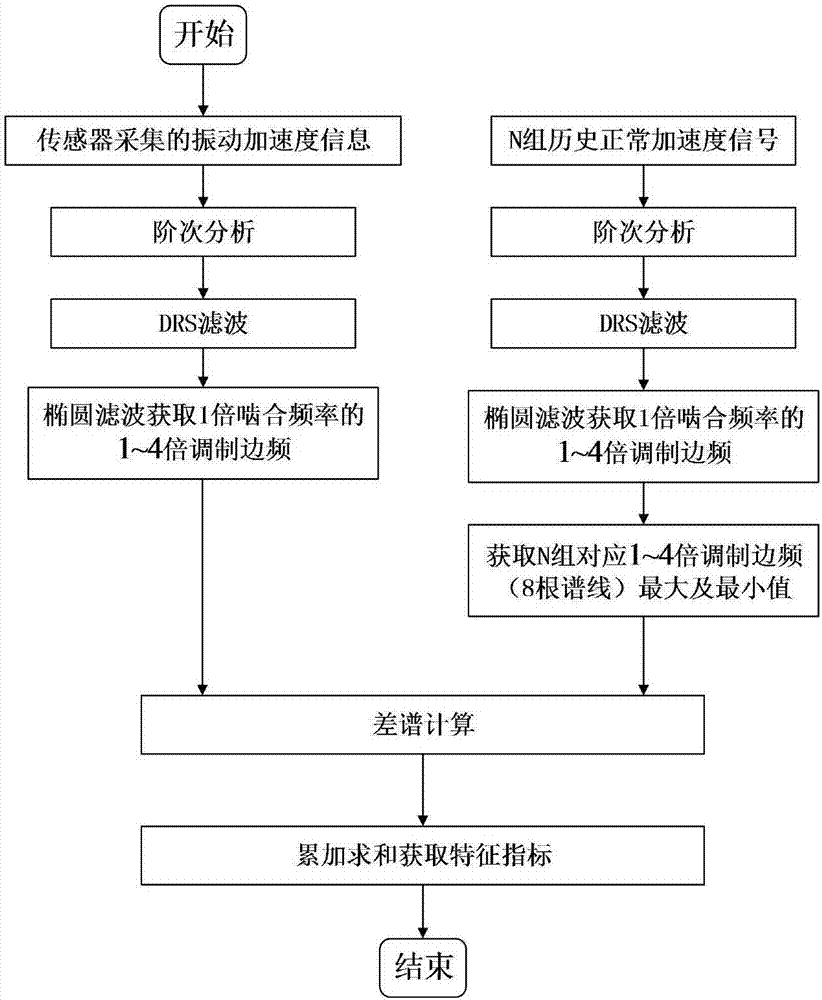

[0024] Such as figure 1 As shown, a gear condition monitoring index extraction method based on discrete random separation algorithm includes the following steps:

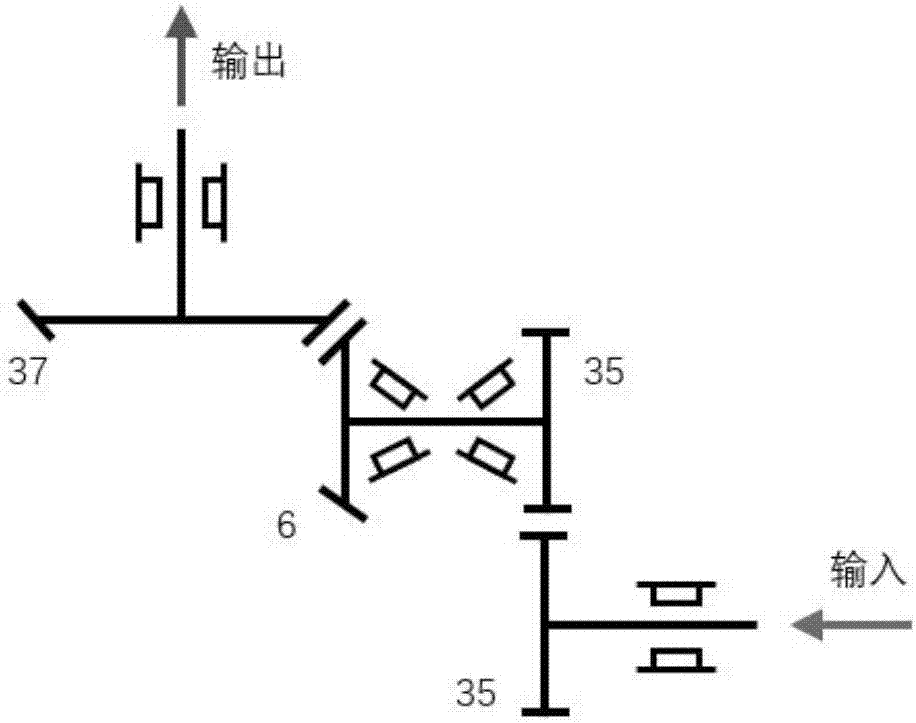

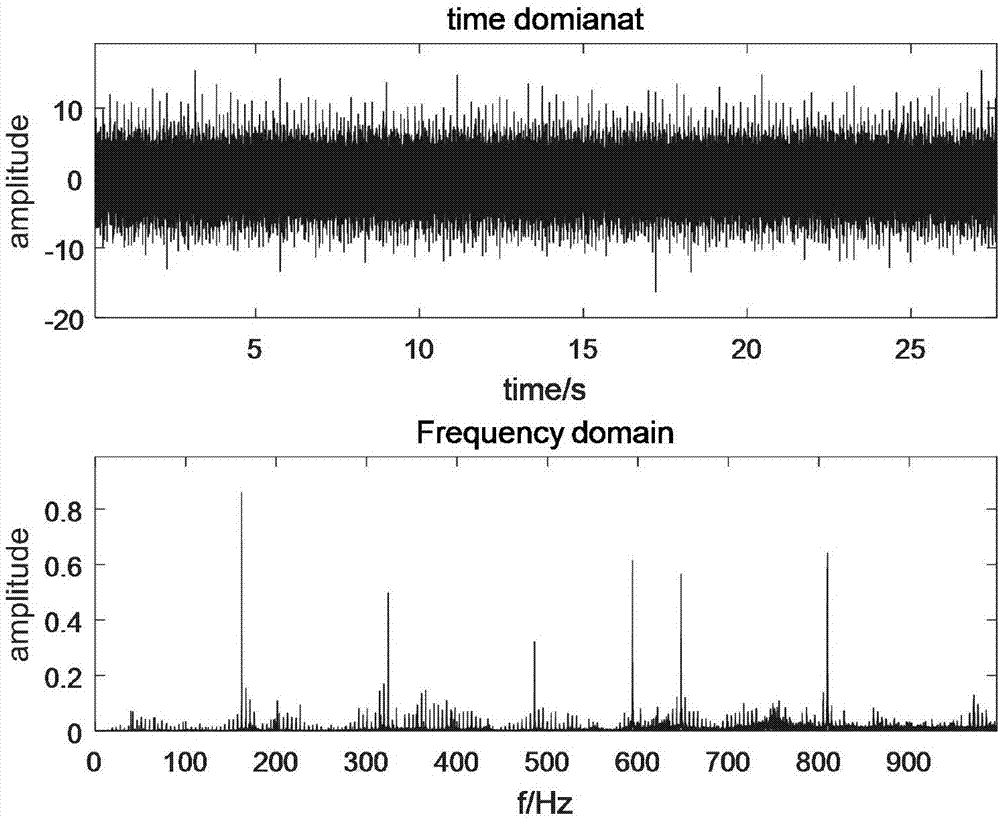

[0025] 1) Calculate the maximum and minimum values of the side frequency amplitudes of 1 to 4 times the meshing order of the reference signal: N groups of normal gearbox vibration acceleration signals are sampled through the vibration acceleration sensor, and the sampling frequency is 5120Hz. The axle gear The box is a two-stage transmission, the structure is as follows figure 2 As shown, its structural parameters are as follows: input speed f n =277.5rpm, the first stage is the meshing of the spur gear pair, the number of teeth of the driving gear is z 1 =35, the number of teeth of the driven gear z 2 =35; the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com