Fault diagnosis and prediction system for nuclear power gear box vibration and oil online monitoring

A technology of fault diagnosis and prediction system, which is applied in the direction of measuring device, testing of mechanical components, testing of machine/structural components, etc. It can solve the problem of not considering seismic performance, unfavorable real-time grasp of the operating state of the gearbox, and cannot fully reflect the equipment. Operation status and other issues to achieve the effect of ensuring safe operation, improving accuracy, and facilitating real-time control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to more clearly illustrate the technical solutions in the embodiments of the present invention or the prior art, the following will briefly introduce the drawings that need to be used in the description of the embodiments or the prior art. Obviously, the accompanying drawings in the following description These are some embodiments of the present invention. Those skilled in the art can also obtain other drawings based on these drawings without creative work.

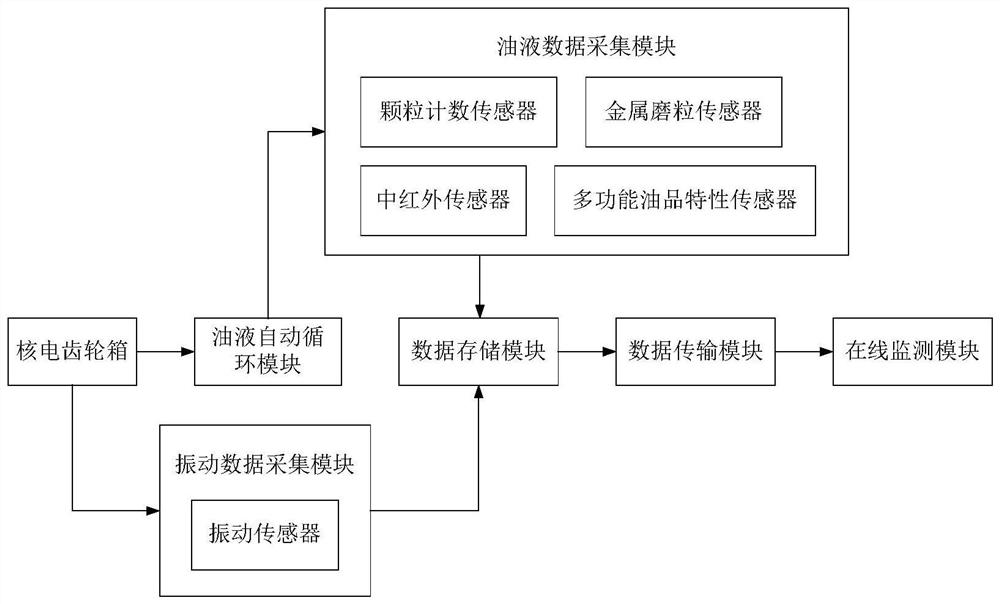

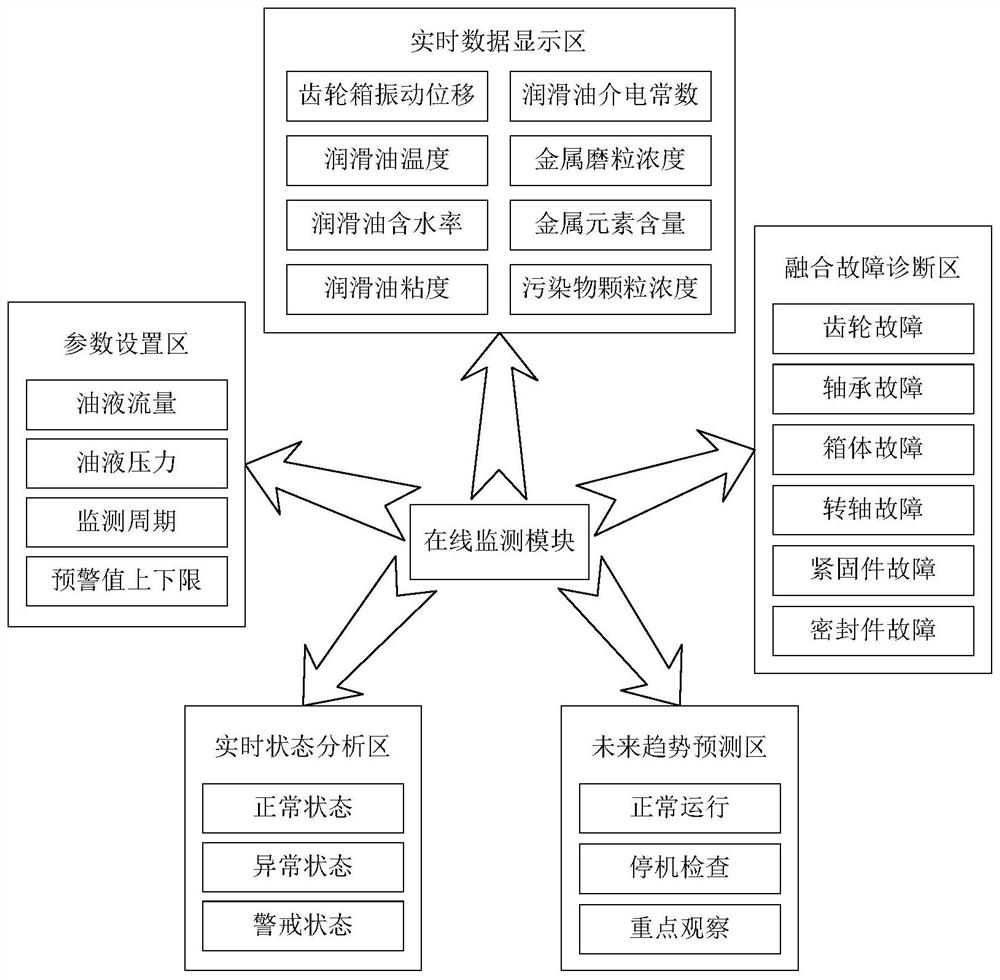

[0030] A fault diagnosis and prediction system for nuclear power gearbox vibration and oil on-line monitoring proposed by the present invention, such as figure 1 As shown, the system includes a nuclear power gearbox, an automatic oil circulation module, an oil data acquisition module, a vibration data acquisition module, a data storage module, a data transmission module and an online monitoring module.

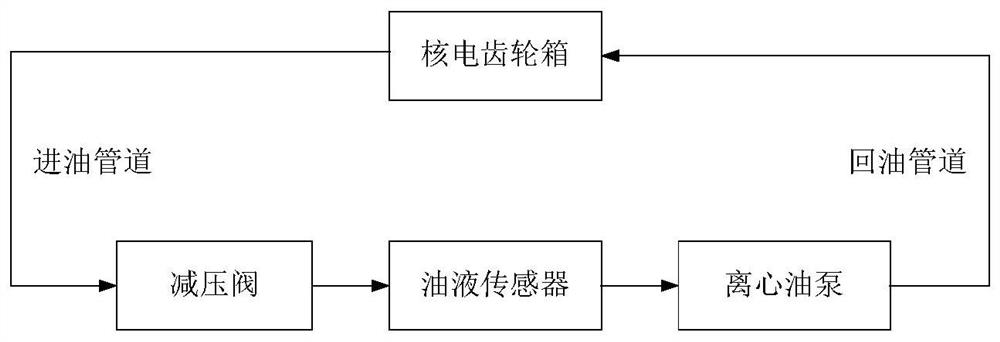

[0031] The automatic oil circulation module is respectively connected with the nuclear power gearbox an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com