An intelligent identification method and identification device for silicon material quality

A silicon material and intelligent technology, applied in the field of intelligent identification method and identification device of silicon material quality, can solve problems such as low work efficiency, difficulty in determining abnormal materials, and different judgment standards, so as to improve work efficiency, avoid classification errors, Identify the effect of classification accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

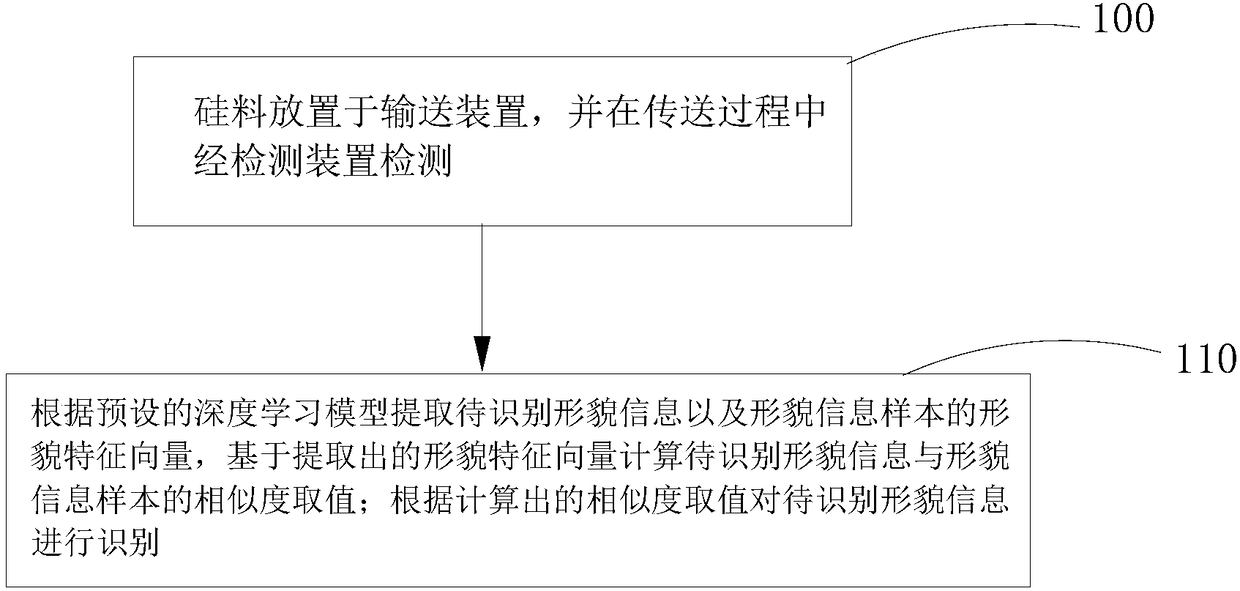

[0024] see figure 1 , the present embodiment provides a method for intelligent identification of silicon material quality, comprising the following steps:

[0025] Step 100, the silicon material is placed on the conveying device, and is detected by the detecting device during the conveying process.

[0026] Step 110, extract the shape information to be recognized and the shape feature vector of the shape information sample according to the preset deep learning model, and calculate the similarity between the shape information to be recognized and the shape information sample based on the extracted shape feature vector value; according to the calculated similarity value, the shape information to be recognized is identified and classified.

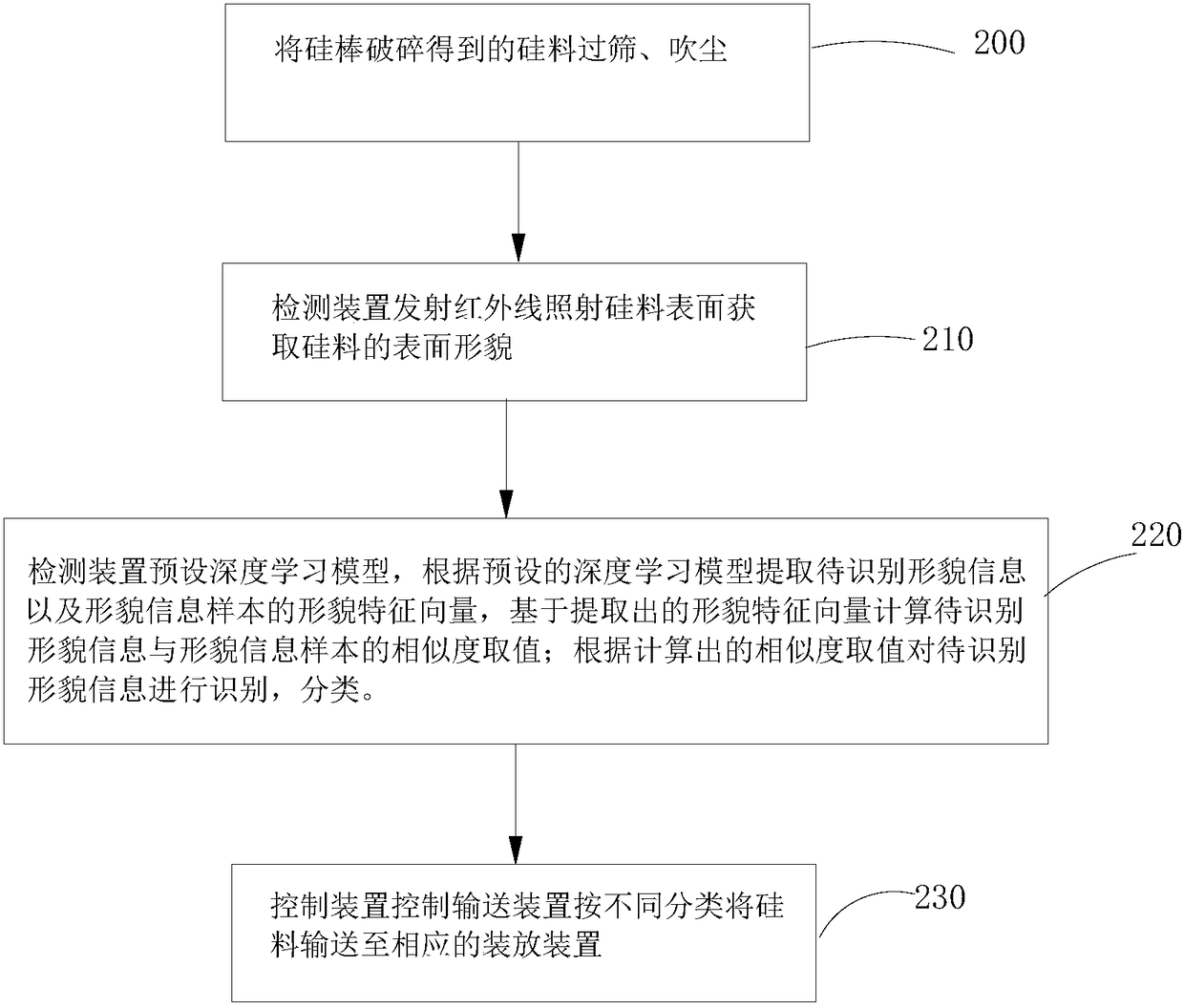

[0027] For details below, see figure 2 .

[0028] Step 200, breaking the silicon rods into silicon materials, and breaking them to facilitate the analysis of the surface structure of the silicon materials.

[0029] Preferably, the steps ...

Embodiment 2

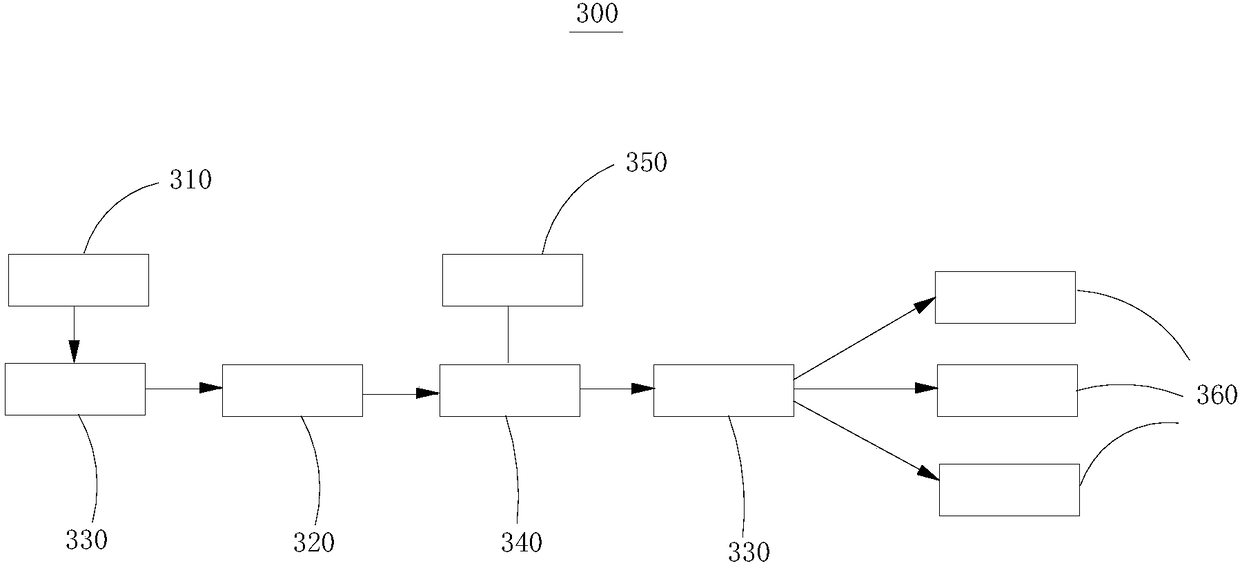

[0047] see image 3 , this embodiment provides an intelligent identification device 300 for the quality of silicon materials, including a crushing device 310 , a screening device 320 , a conveying device 330 , a detection device 340 , a control device 350 and a plurality of loading devices 360 .

[0048] The crushing device 310 is used to crush silicon rods to obtain silicon materials. Preferably, the crushing device 310 is located above the conveying device 330 , and the silicon material obtained after crushing the silicon rods by the crushing device 310 falls directly on the conveying device 330 , which facilitates the transportation of the conveying device 330 .

[0049] During the crushing process of the silicon rods by the crushing device 310 , powder and fine particles are generated, which are removed by the screening device 320 . Preferably, the screening device 320 is set on the conveying device 330, and the silicon material is screened during the conveying process. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com