A kind of anti-arsenic poisoning SCR denitrification catalyst and preparation method thereof

A denitrification catalyst and arsenic poisoning technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve problems such as poor activity, short life, and rapid reduction in denitrification efficiency, and achieve extended life and inhibition depth Poisoning, the effect of improving the ability to resist arsenic poisoning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

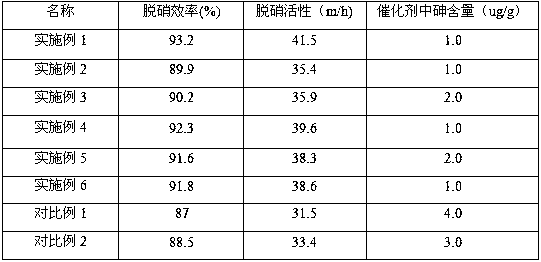

Examples

Embodiment 1

[0028] A method for preparing an anti-arsenic poisoning SCR denitration catalyst includes the following steps:

[0029] (1) Mix ammonium metavanadate, ammonium molybdate and bismuth nitrate to obtain an active raw material; the mass ratio of vanadium, molybdenum and bismuth in the active raw material is 0.83:6.66:3.59;

[0030] (2) Mix the active raw material obtained in step (1) with citric acid in a mass ratio of 1:2, grind for 30 minutes, then dry at 80°C for 8 hours, and calcinate at 400°C for 6 hours to obtain active powder;

[0031] (3) Prepare a mixed mud which is made by mixing the following raw materials according to mass percentages: 15 parts of active powder obtained in step (2), 10 parts of structural additives, 0.1 part of tung oil, 2 parts of silica sol, 0.1 part of methyl cellulose, 2 parts of glass fiber, 73 parts of titanium dioxide and 45 parts of deionized water; wherein, the structural aid is obtained by mixing calcium oxide and tin oxide in a mass ratio of 1:1;

...

Embodiment 2

[0036] A method for preparing an anti-arsenic poisoning SCR denitration catalyst includes the following steps:

[0037] (1) Mix ammonium metavanadate, ammonium molybdate and bismuth nitrate to obtain an active raw material; the mass ratio of vanadium, molybdenum and bismuth in the active raw material is 0.056:3.33:4.48;

[0038] (2) Mix the active raw materials obtained in step (1) with citric acid in a mass ratio of 1:4, grind for 90 minutes, then dry at 100°C for 6 hours, and calcinate at 600°C for 4 hours to obtain active powder;

[0039] (3) Prepare a mixed mud, the mixed mud is made by mixing the following raw materials according to mass percentage: 10 parts of the active powder obtained in step (1), 18 parts of structural additives, 0.5 parts of tung oil, 3 parts of silica sol, 0.05 parts of methyl cellulose, 6 parts of glass fiber, 66 parts of titanium dioxide and 55 parts of deionized water; wherein, the structural aid is obtained by mixing calcium nitrate and tin nitrate in ...

Embodiment 3

[0044] A method for preparing an anti-arsenic poisoning SCR denitration catalyst includes the following steps:

[0045] (1) Mix ammonium metavanadate, ammonium molybdate and indium chloride to obtain an active raw material; the mass ratio of vanadium, molybdenum and indium in the active raw material is 0.056:3.33:1.65;

[0046] (2) Mix the active raw material obtained in step (1) with citric acid in a mass ratio of 1:3, grind for 30 minutes, then dry at 80°C for 8 hours, and calcinate at 400°C for 6 hours to obtain active powder;

[0047] (3) Prepare a mixed mud, the mixed mud is made by mixing the following raw materials according to mass percentage: 7 parts of active powder obtained in step (1), 18 parts of structural additives, 0.1 part of tung oil, 1 part of silica sol, 0.05 parts of methyl cellulose, 2 parts of glass fiber, 73 parts of titanium dioxide and 50 parts of deionized water; wherein, the structural aid is obtained by mixing calcium chloride and tin chloride in a mass r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com