Self-protection track buckle

A technology for rail fasteners and rails, applied in the field of self-protection rail fasteners, can solve the problems of not being able to fundamentally eliminate hidden dangers, increase the amount of daily maintenance operations and maintenance costs, and achieve the effect of preventing loosening or tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

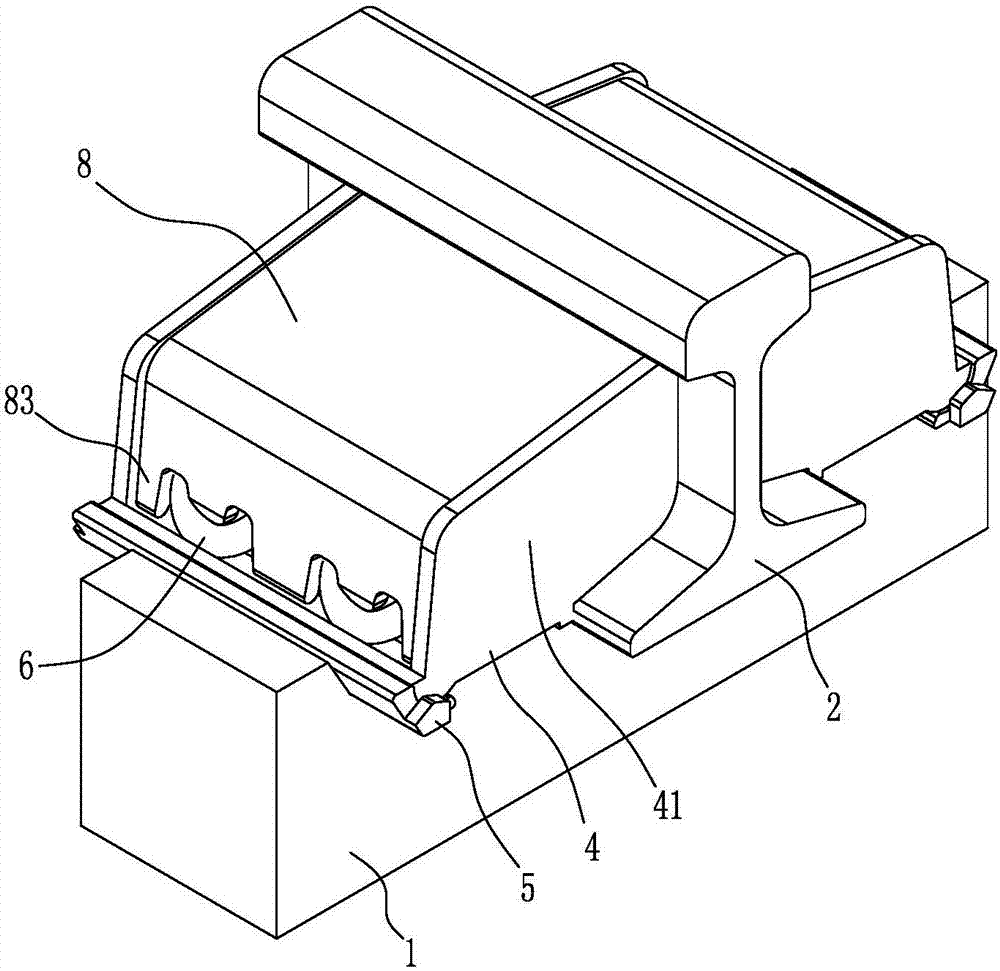

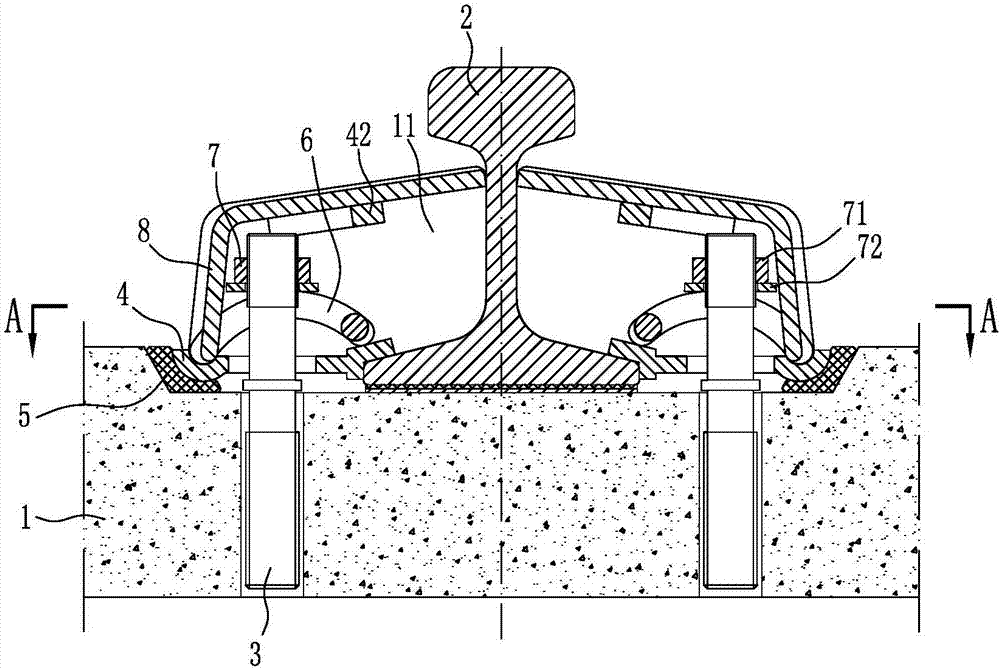

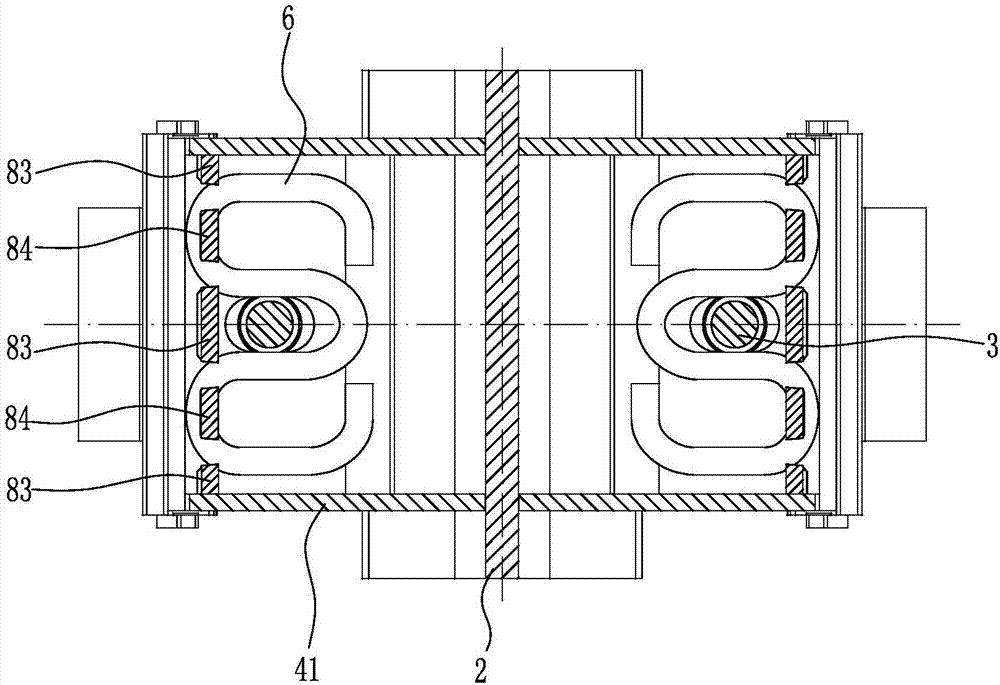

[0023] Embodiment one: if Figure 1 to Figure 4 As shown, the self-protective rail fastener is symmetrically arranged on both sides of the rail 2, that is, this embodiment is used in pairs; it includes a spiral spike 3 fixedly installed on the sleeper 1, and the spiral spike 3 is located on the A gauge baffle 4 is installed above the sleeper 1, and a baffle seat 5 is installed between the gauge baffle 4 and the sleeper 1; Elastic bar 6, described rail gauge baffle plate 4 is provided with the elastic bar arc groove corresponding to described elastic bar 6, and described elastic bar arc groove is well known to those skilled in the art, no longer Repeat; the spiral spike 3 is located above the elastic strip 6 and is provided with an elastic strip fastening device 7, and the gauge baffle 4 adopts an oblong hole gauge baffle of the elastic strip I-type fastener. The bar 6 adopts the A-type elastic strip of the elastic strip I-type fastener, the said baffle seat 5 adopts the baffl...

Embodiment 2

[0029] Embodiment two: if Figure 5 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that: the side guard connecting plate 42 is arranged parallel to the dust-proof surface 81, and the dust-proof surface 81 is provided with a countersunk hole 85 , the side guard connecting plate 42 is provided with a fixing screw hole corresponding to the countersunk hole 85; in this embodiment, the dust cover 8 can be further fixed by using the hexagon socket countersunk head bolt, on the one hand, it can prevent the The loosening of the above-mentioned dust cover 8 can, on the other hand, prevent irrelevant personnel from tampering or even stealing. Of course, the countersunk bolts can also be specially made in the form of an inner triangle, which is well known to those skilled in the art and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com