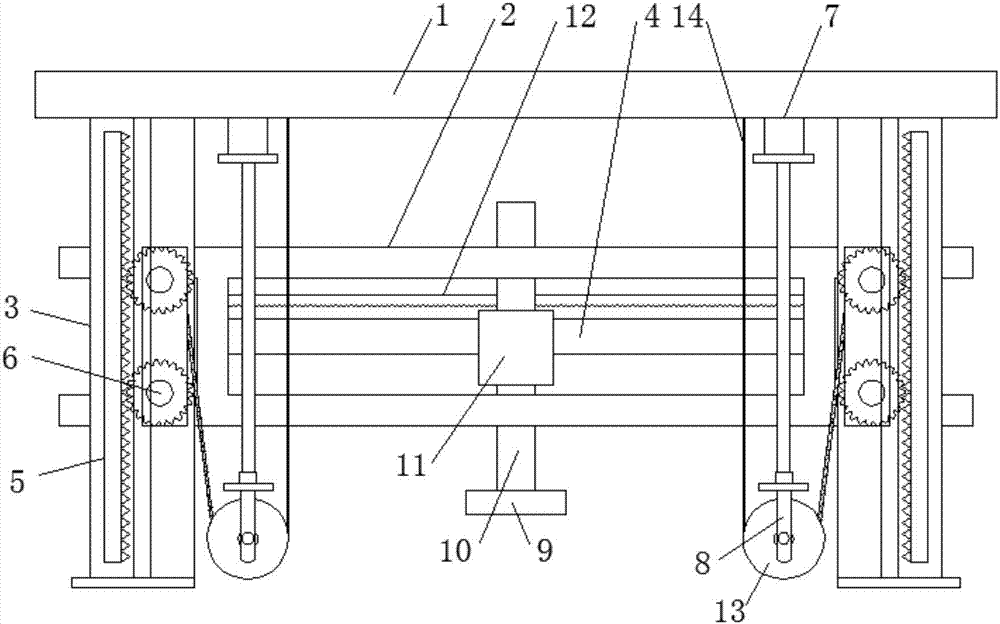

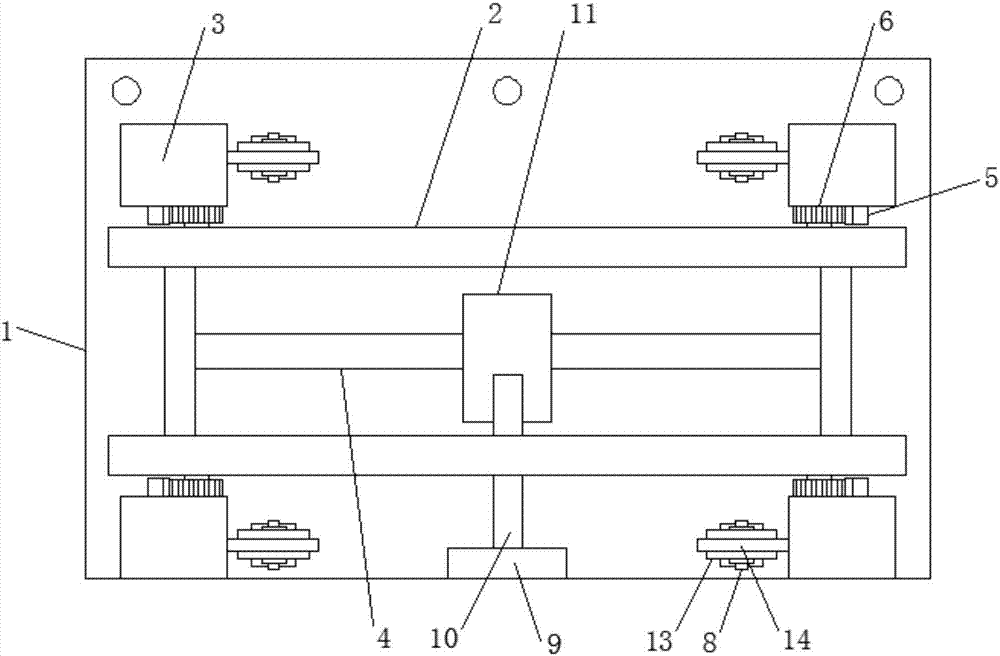

Multi-degree-of-freedom high-rise building external wall plastering machine

A high-rise building, degree-of-freedom technology, applied in the direction of architecture and building structure, can solve the problems of poor painting effect, small freedom of movement of the painting machine, poor stability of the painting machine, etc., and achieves high degree of freedom, good movement stability, Good effect of painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

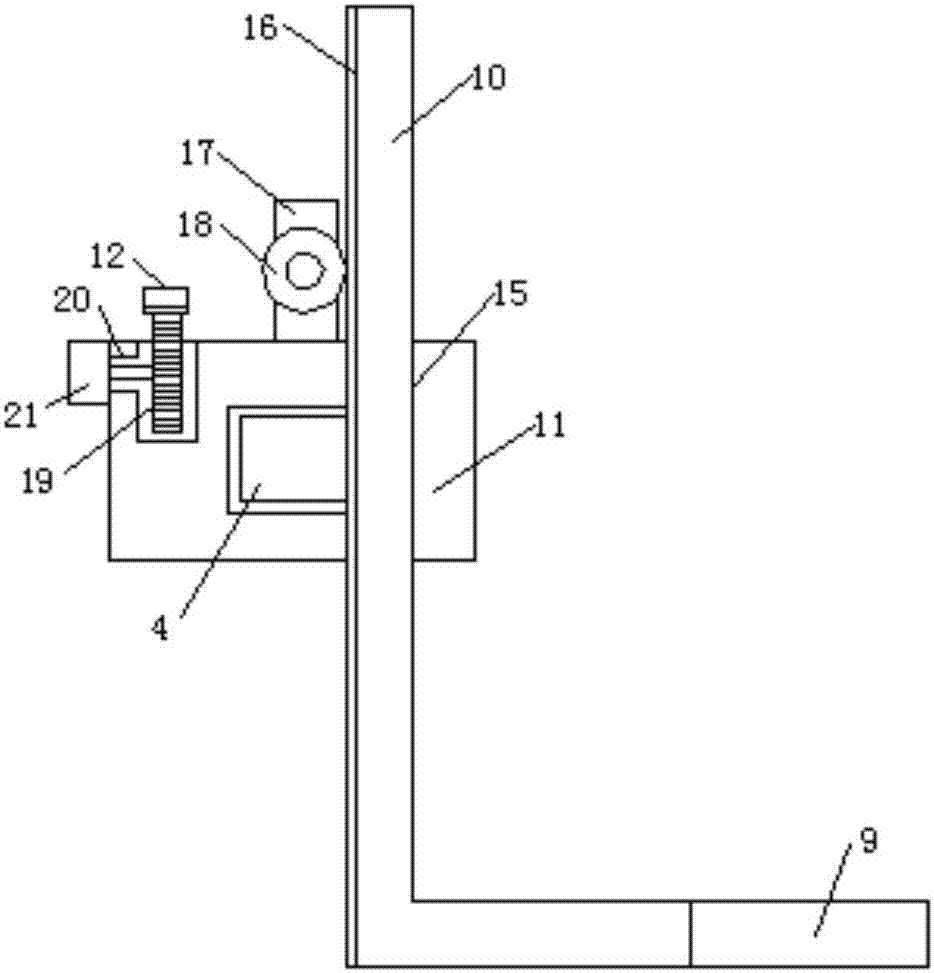

[0030] Embodiment: The top plate 1 is equipped with a counterweight to assist and fix it on the roof of the building, and the reinforcement is stable. The hydraulic cylinder 7 drives the fixed frame 8 to move up and down, so that the steel rope 14 is wound in different directions on the pulley 13. The retractable length realizes the adjustment of different heights of the lifting frame 2, and at the same time cooperates with the first gears 6 on both sides of the lifting frame 2 to move up and down on the first rack 5 on the support rod 3 to ensure that the lifting frame 2 runs smoothly when lifting; Frame 2 firstly adjusts the height in a large range, and then the spraying machine works. The spraying machine is placed on the roof of the building. The fourth motor 911 drives the spray gun rod 912 and the spray gun head 913 to adjust the position. After the adjustment, the spray gun head 913 starts Spraying, while spraying, the second motor 17 drives the third gear 18 to rotate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com