A kind of hydraulic lifting working platform and platform lifting method

A working platform and hydraulic lifting technology, which is applied in the direction of lifting frame, lifting device, etc., can solve the problems that it is difficult to meet the operation requirements of the launch tower, the lifting height of the hydraulic lifting platform is small, and the stability of the working platform is poor, so as to achieve simple design and ensure lifting Stability, material and cost saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

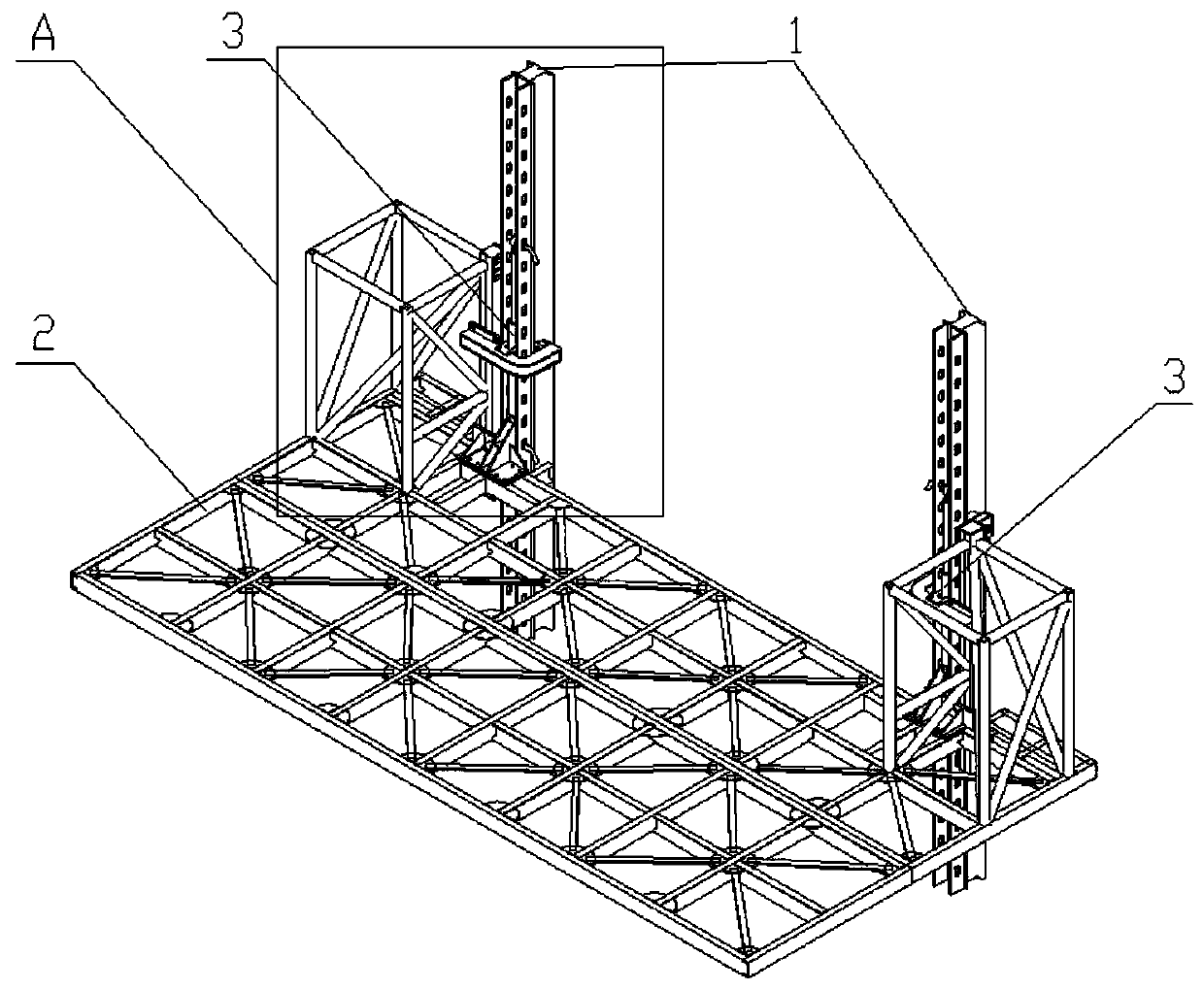

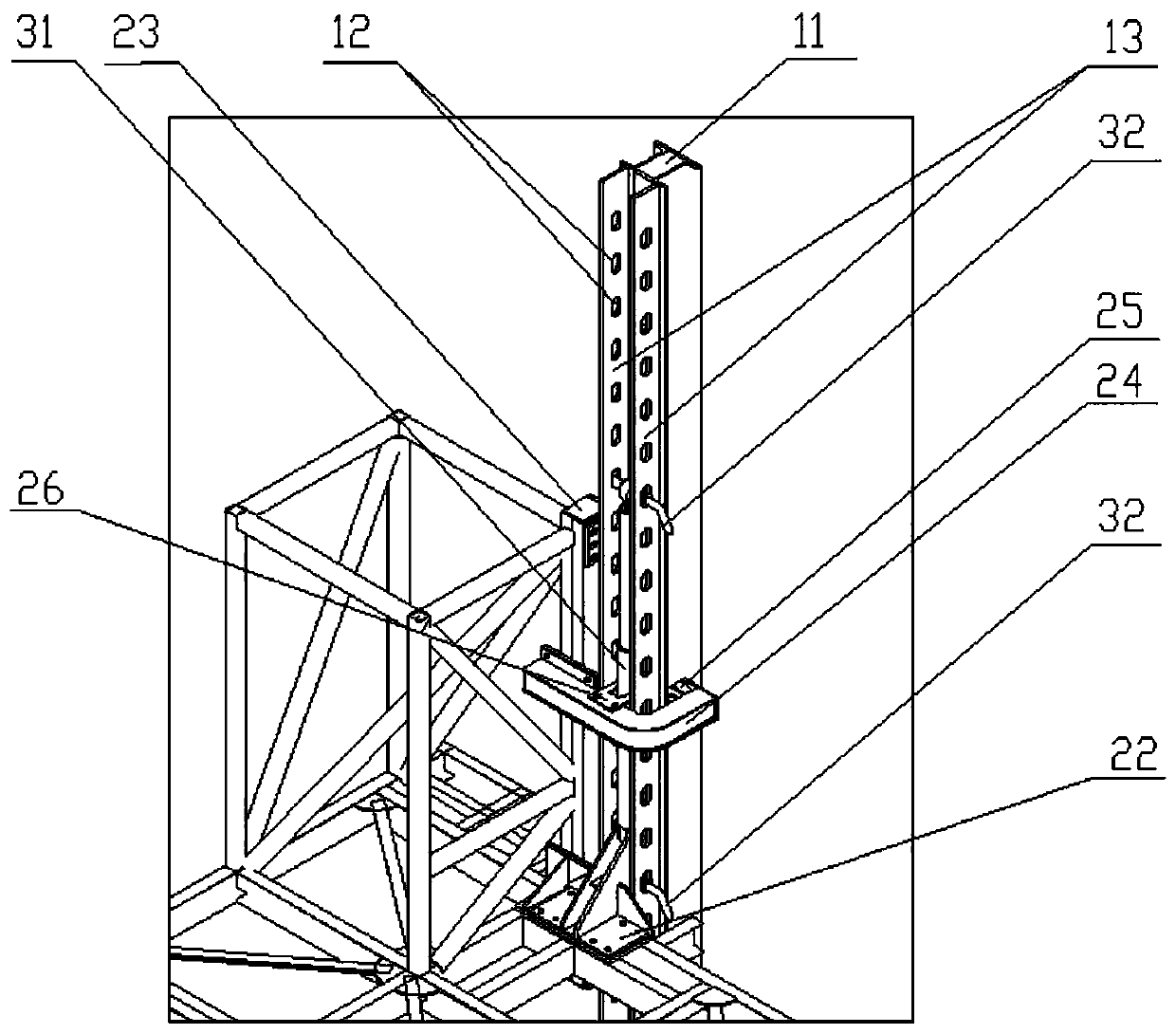

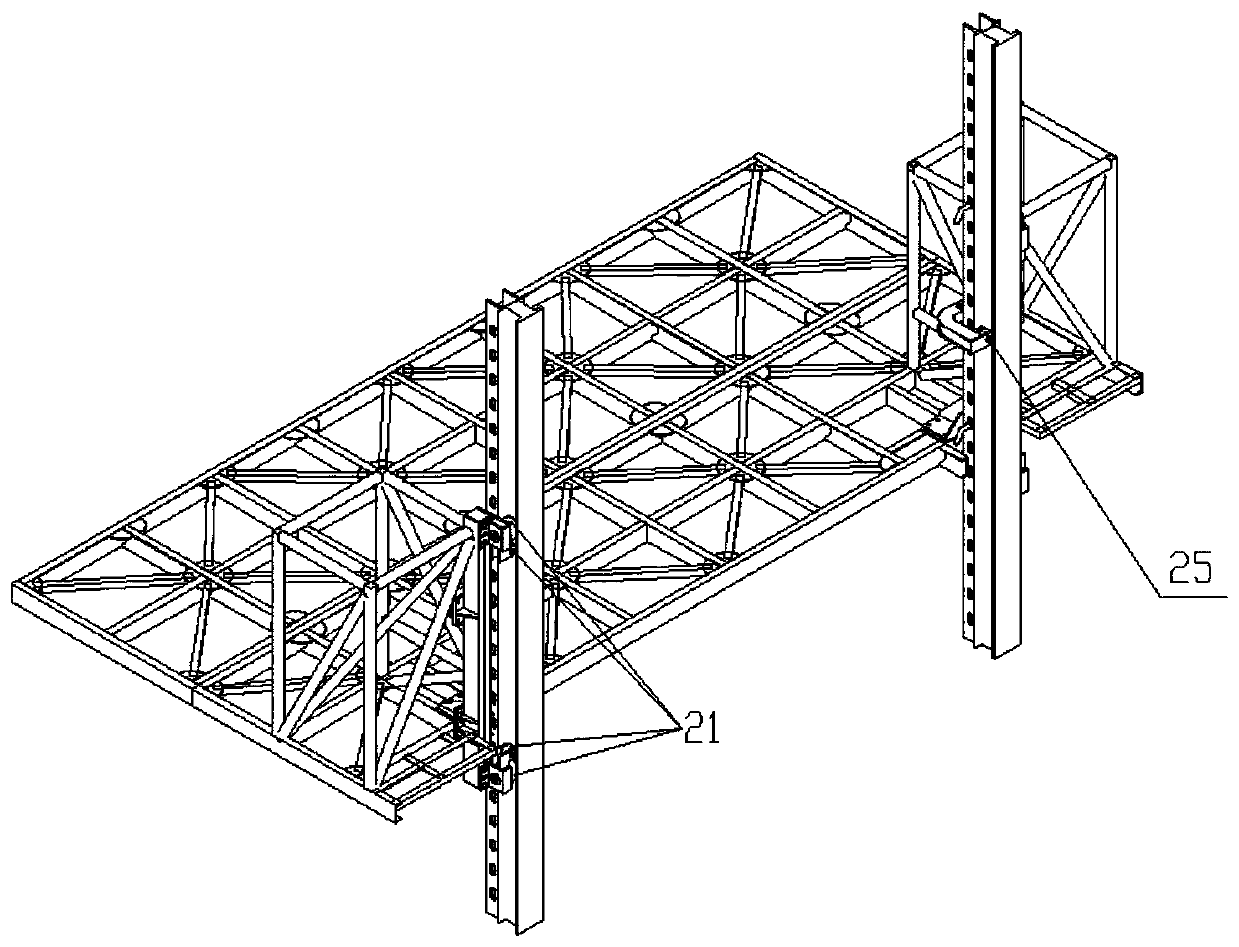

[0030] see figure 1 and figure 2 As shown, the embodiment of the present invention provides a hydraulic elevating work platform, including a support 1 , a platform 2 and a hydraulic system 3 .

[0031] The bracket 1 includes at least one guide rail 11 , and the bracket 1 is provided with a plurality of connecting holes 12 along the length direction of the guide rail 11 . Specifically, the connecting hole 12 is an oblong hole.

[0032] The side of the guide rail 11 close to the platform 2 is provided with two wing plates 13 arranged along the length direction of the guide rail 11 , and a plurality of connecting holes 12 are arranged on the two wing plates 13 at intervals.

[0033] In another embodiment of the present invention, the number of guide rails 11 is two, and the two guide rails 11 are arranged symmetrically with respect t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com