A test device for detecting friction performance of a joint bearing liner and its installation method

A friction performance and test device technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of easy fracture of the main shaft, achieve the effects of optimizing detection tests, saving materials, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings.

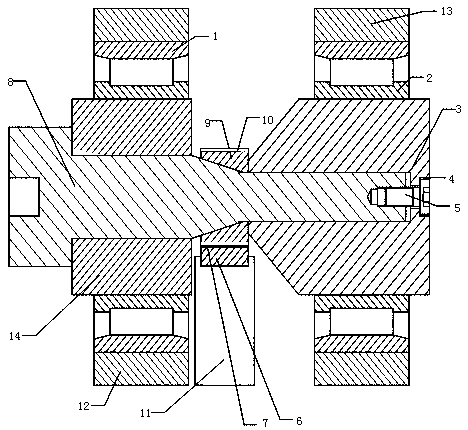

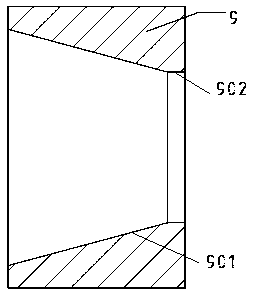

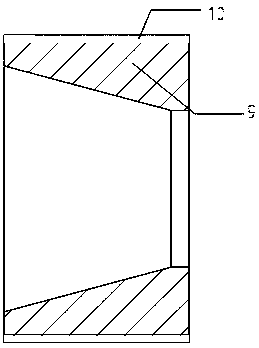

[0048] Such as figure 1 As shown, a test device for detecting the friction performance of a joint bearing liner includes a main shaft 8, a left support structure arranged on the main shaft 8, a right support structure, and a friction pair between the left support structure and the right support structure, wherein, The main shaft 8 is arranged horizontally and from left to right is a large-diameter section 801, a tapered body section 802 with a large left and a small right-hand section, and a small-diameter section 803; the left support structure is arranged on the large-diameter section 801, and the right support structure is arranged on the On the small diameter section 803; the friction pair includes a metal ring 9, a ceramic layer 10, a friction pair outer ring 6, a liner 7 and a hydraulic support block 11, wherein the outer peripheral surface of the metal ring 9 is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| Cylindricity | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com