Intelligent replenishment and sorting system

A replenishment and intelligent technology, applied in instruments, data processing applications, logistics, etc., can solve problems such as inability to improve efficiency, low work efficiency, and difficult to reduce picking error rate, so as to reduce picking error rate and improve work efficiency , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

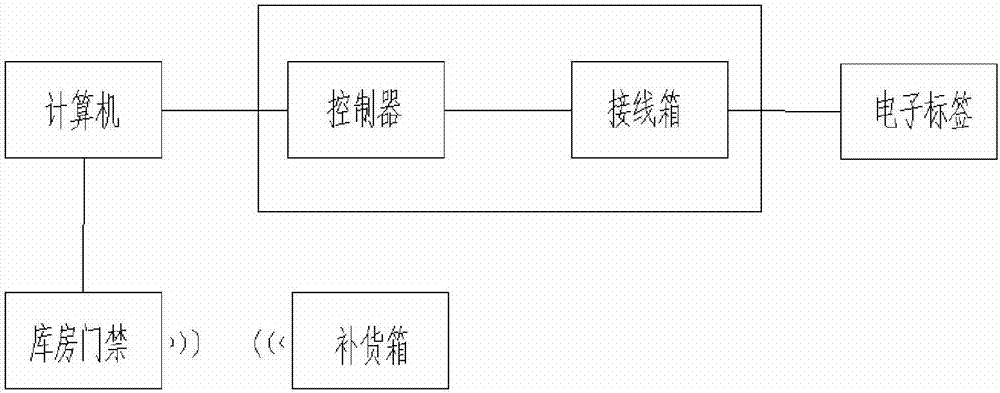

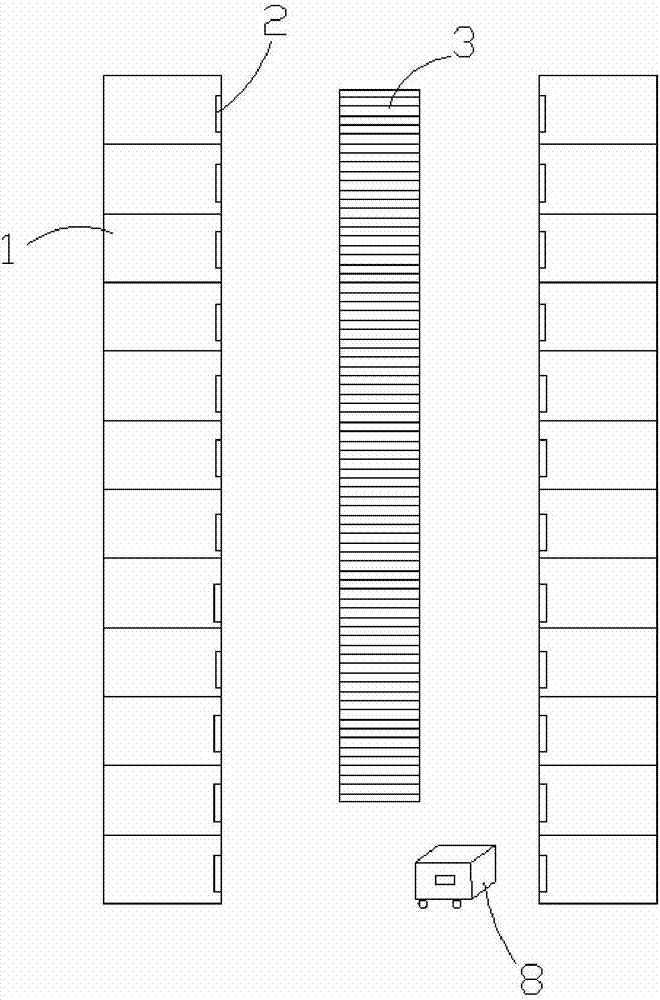

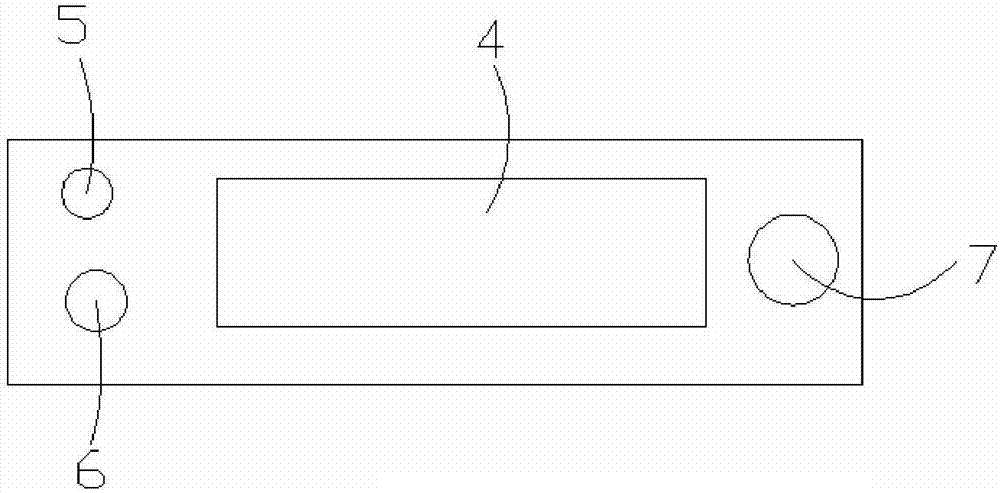

[0022] Such as figure 1 , figure 2 and image 3 As shown, an intelligent replenishment picking system includes a control device, a replenishment vehicle and a warehouse, the control device includes a computer and a controller, the computer is installed with a database and an operation module, and the computer is connected to the controller through a data interface; the replenishment There is an RFID tag inside the car, and the RFID tag contains product information, mainly including the product number, quantity, merchant and other information of the product.

[0023] The warehouse inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com