Process for machining shielding window through buckle cover sectional materials

A technology for protective windows and profiles, applied in metal processing equipment, manufacturing tools, window/door frames, etc., can solve problems such as not very suitable for snap-on protective windows, environmental pollution, low efficiency, etc., achieve good welding characteristics, improve quality, the effect of improving the efficiency of welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The invention provides a process for processing a protective window by using a buckle cover type profile, which includes the following steps:

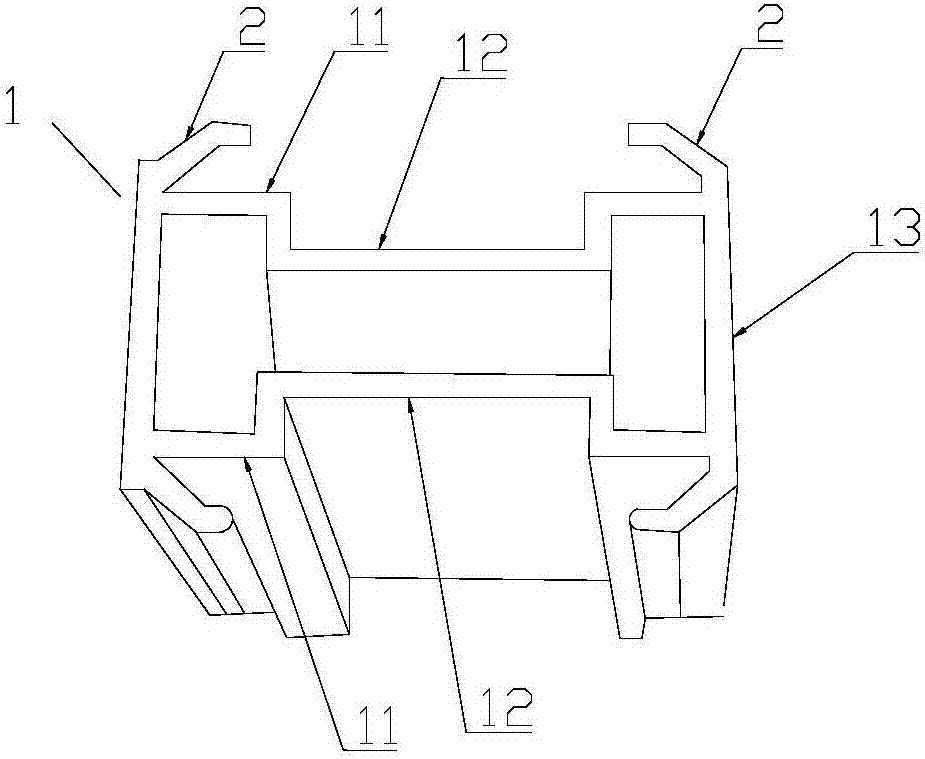

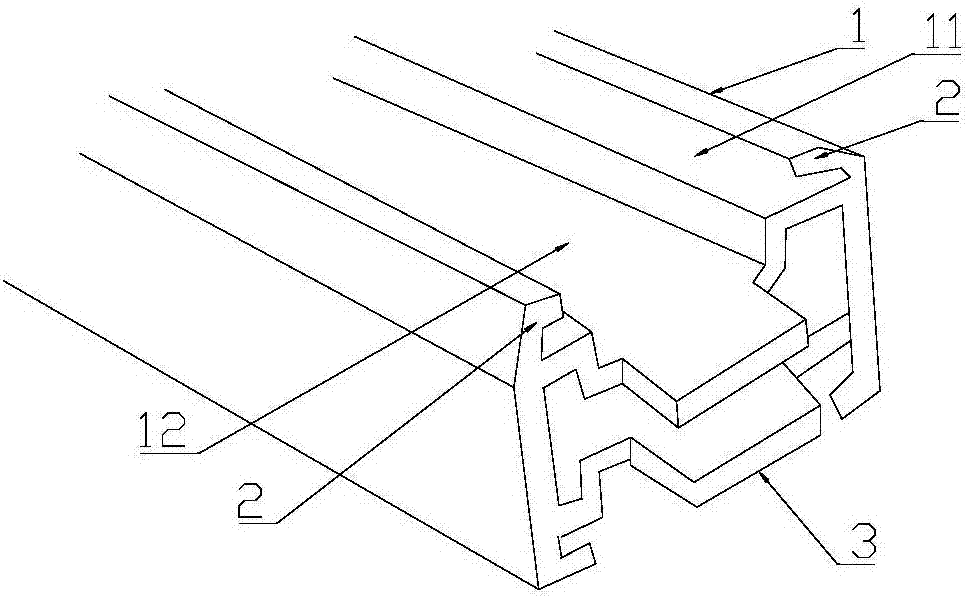

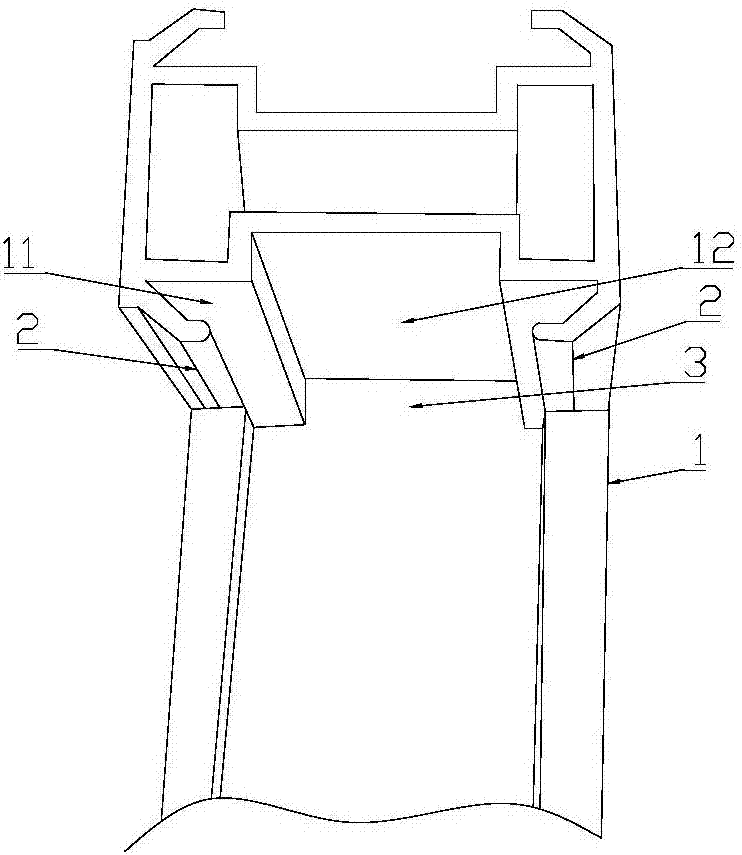

[0026] (1) Process the main profile and the connecting profile used to connect with the main profile, such as figure 1 As shown, the main profile and the connecting profile both include a square frame 1, and grooves 12 are provided on the opposite side walls 11 of the square frame 1, and the grooves 12 are formed by indenting the side walls 11, which can be used to accommodate welding slag and prevent The outflow of welding slag affects the fastening of the buckle cover;

[0027] (2) Apply a film to the groove on the square frame, and carry out surface color treatment on the side wall 13 of the main profile and the connecting profile that is not provided with a groove. The film can ensure that the groove is dry and clean, and will not be affected by the surface color treatment. , to maintain the good welding properties of alumi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com