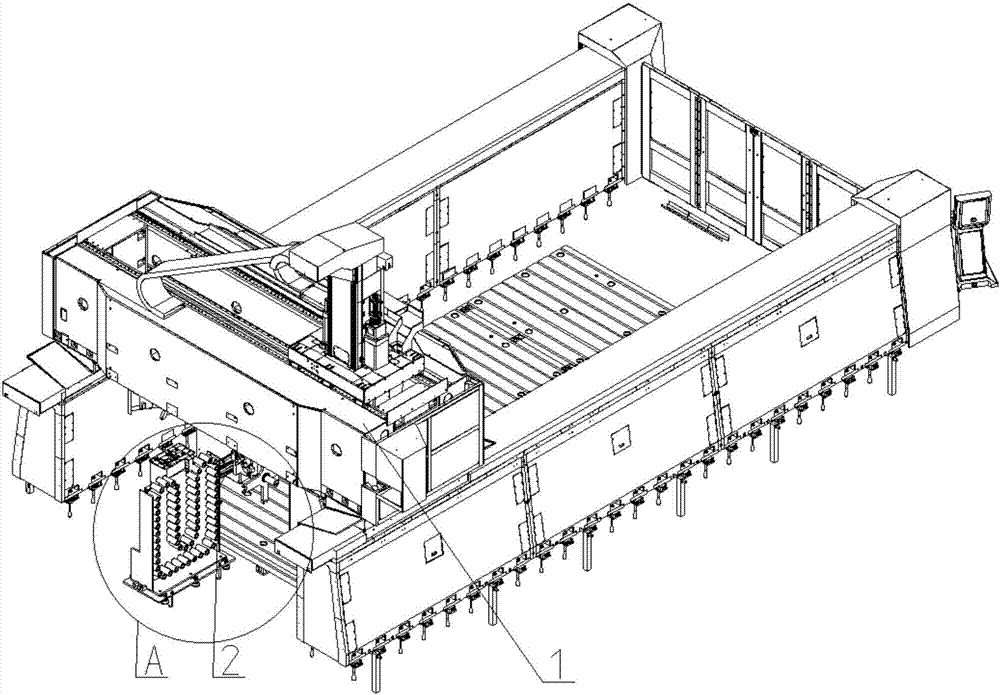

Dual-specification tool holder automatic tool changing device for five-axis gantry machining center with multifunctional cutter head

A technology of automatic tool change and machining center, which is applied in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problems of functional limitations of milling heads and the inability to realize automatic tool change, etc., and achieve the effect of reducing restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific implementation manners of the present invention will be described in further detail below with reference to the accompanying drawings.

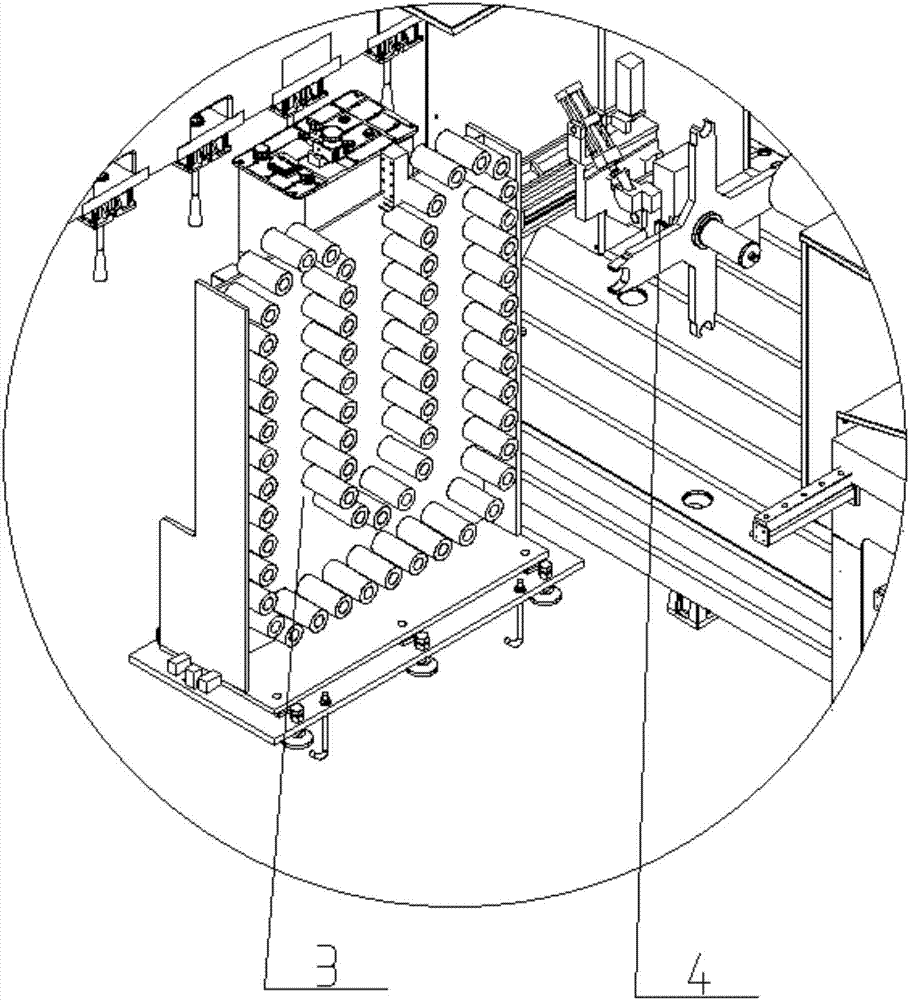

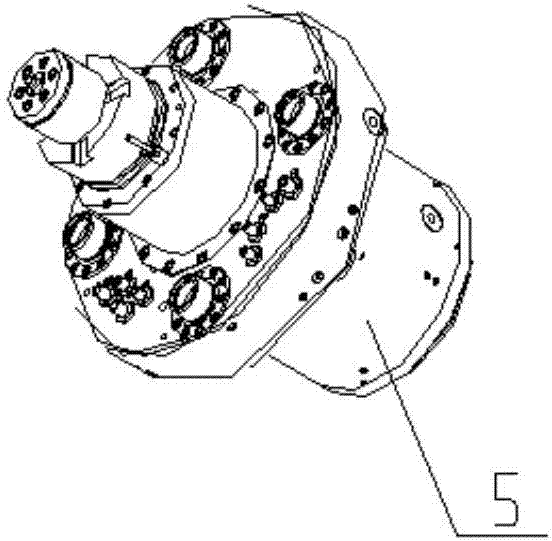

[0023] Such as Figure 1 to Figure 9 In the shown automatic tool changer for double-standard tool holders of the five-axis gantry machining center with multi-functional milling head, the tool changer 2 is installed on the rear side of the five-axis gantry machining center 1, and includes a tool magazine 3 and a tool change mechanism 4. The tool magazine 3 is a chain tool magazine, and two kinds of tool holders 13 of different specifications are arranged in the tool holder hole of the chain magazine; the tool changing mechanism 4 includes a tool changing arm 21 and a tool changing arm moving device, and The arm moving device is installed on the inner side of the tool magazine 3, and the tool changing arm 21 is rotatably installed on the moving device of the tool changing arm, and is turned over by the turning oil cylinder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com