A longitudinal and horizontal beam structure under the electric vehicle body

A technology for longitudinal and horizontal beams and electric vehicles, which is applied to the substructure, upper structure, and sub-assembly of the upper structure. It can solve the problems of decreased safety factor of the whole vehicle and the inability to arrange the longitudinal beams under the floor, etc., and achieve the improvement of the layout space and the passenger's footsteps. Effects of space optimization and ground clearance elimination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

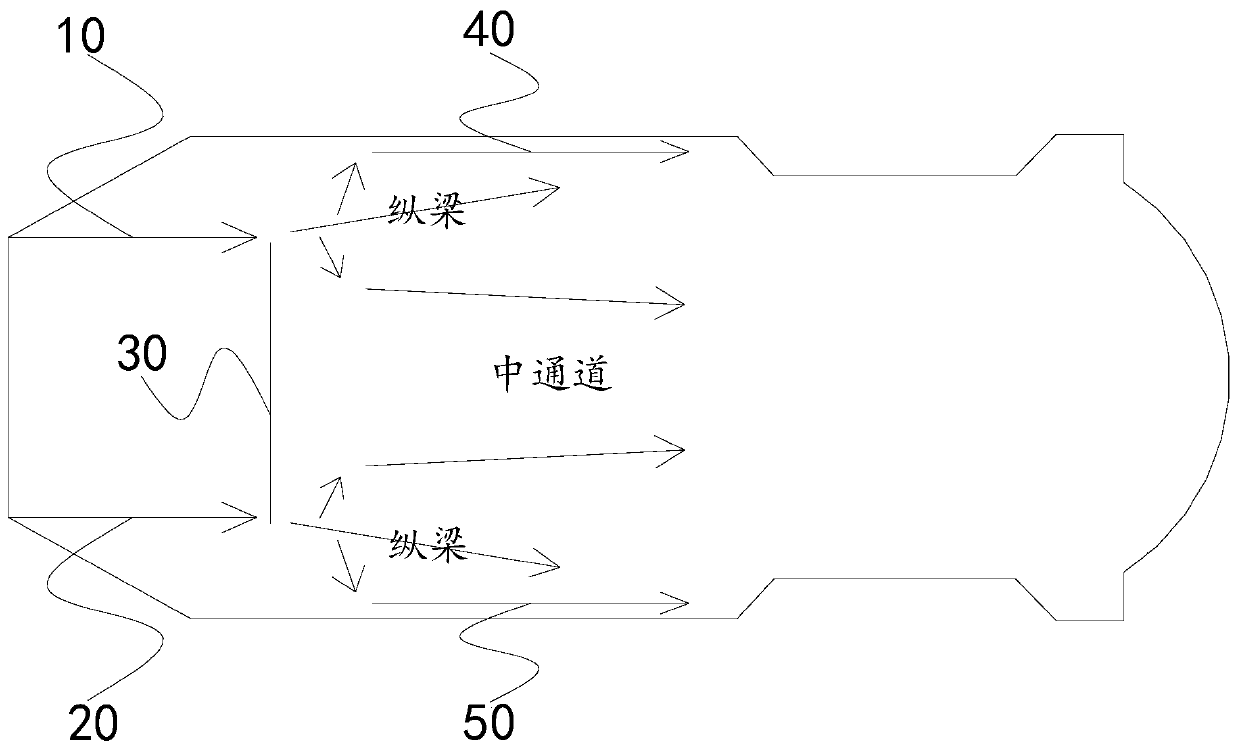

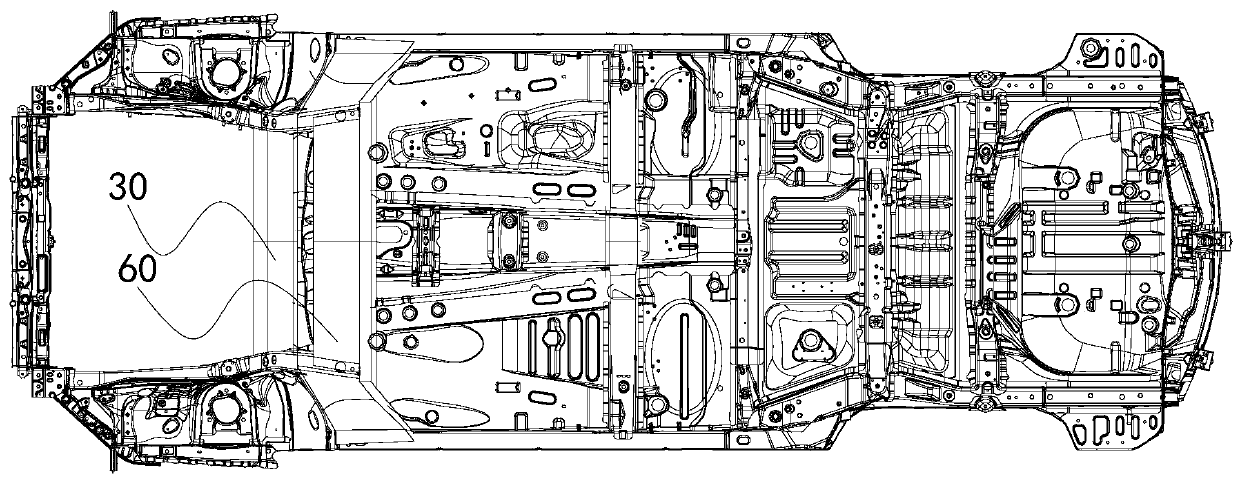

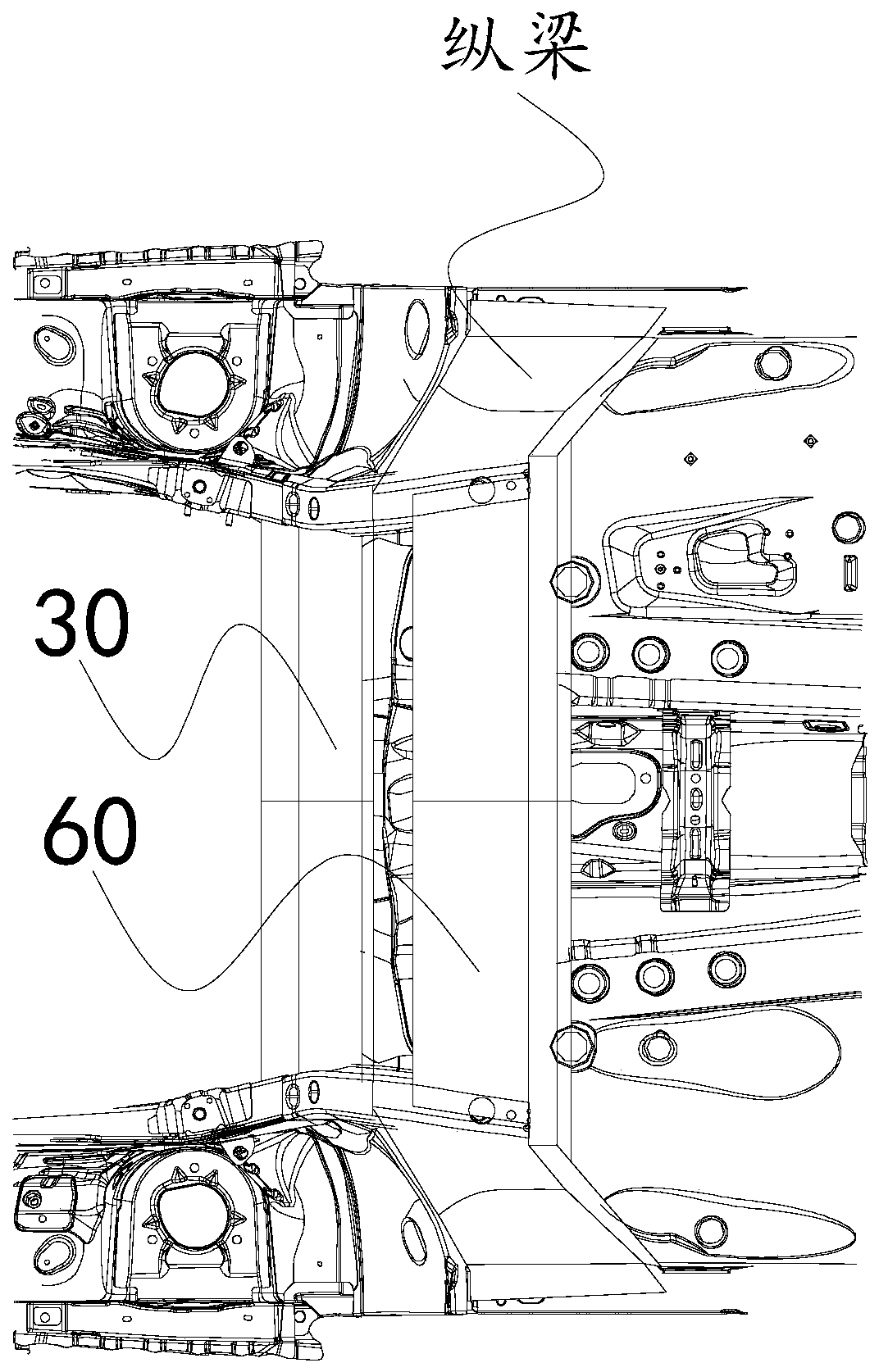

[0030] see Figure 1 to Figure 5 , the present embodiment is a vehicle body longitudinal beam structure under the electric vehicle, including the first front longitudinal beam 10, the second front longitudinal beam 20, the first cross beam 30, the first threshold beam 40, the second threshold beam 50 and the middle channel 80 , also includes a second cross beam 60, a third cross beam 70, the end of the first front longitudinal beam is arranged above the first door sill beam, and the end of the second front longitudinal beam is arranged above the second door sill beam; The two ends of the first cross beam are respectively connected with the middle sections of the first front longitudinal beam and the second front longitudinal beam, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com