Rotor head of centrifugal waving flapping hinge

A technology of waving hinges and rotor heads, applied in the field of unmanned aerial vehicles, can solve the problems of loss of kinetic energy, cumbersomeness, and unsuitability for unmanned aerial vehicles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

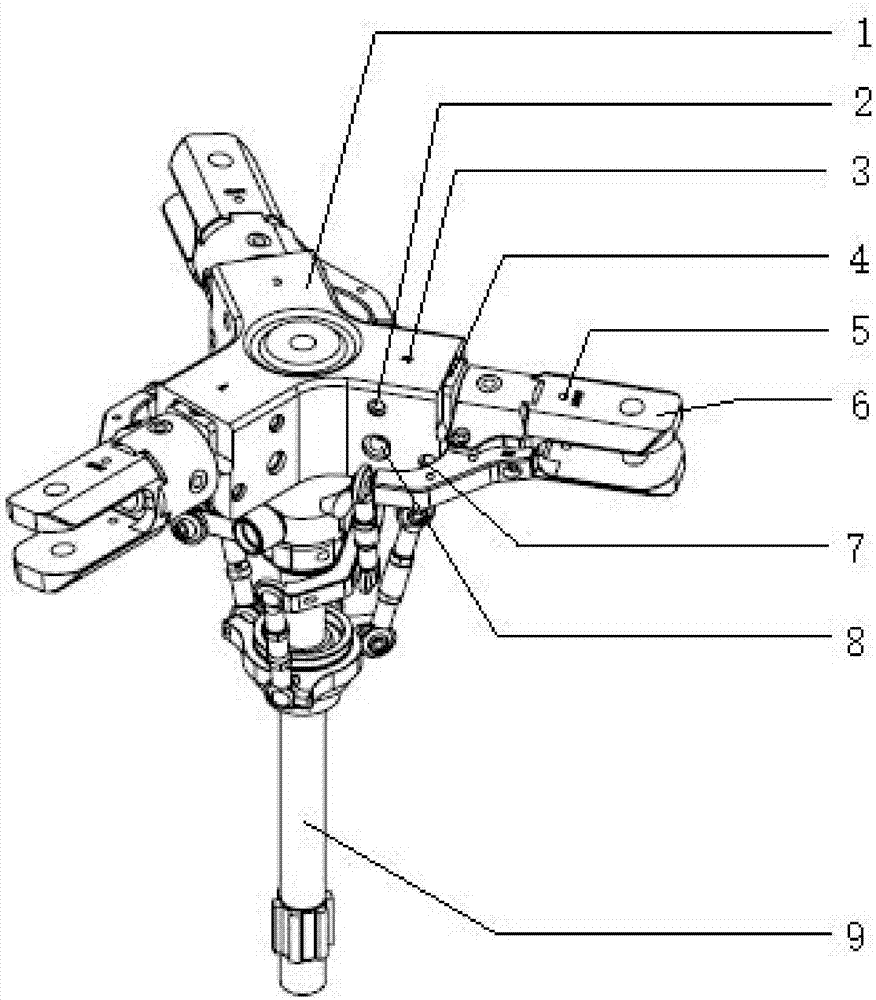

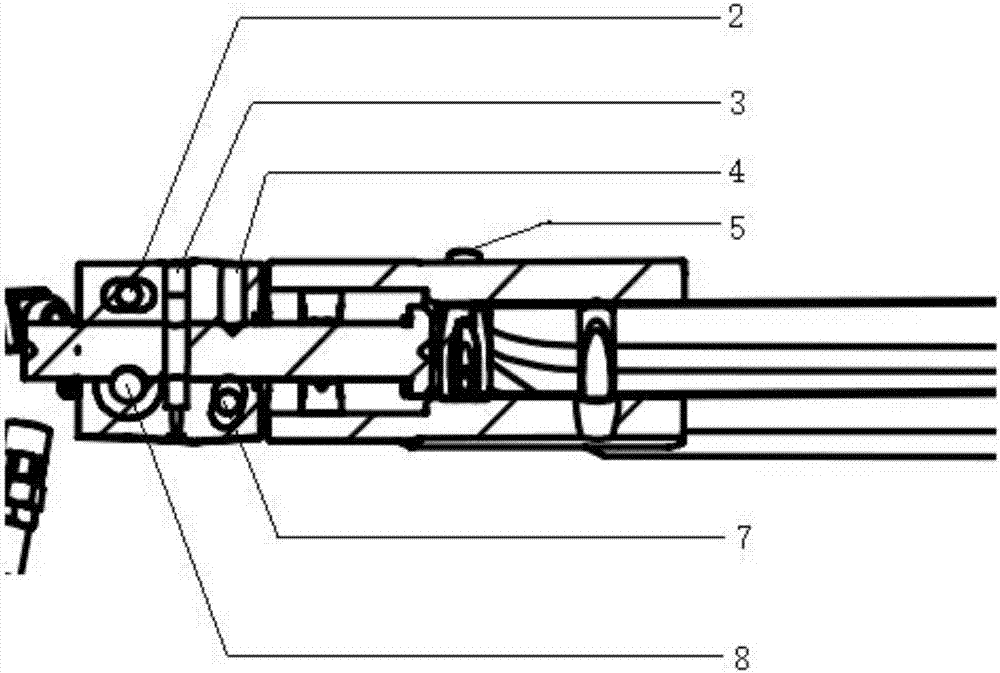

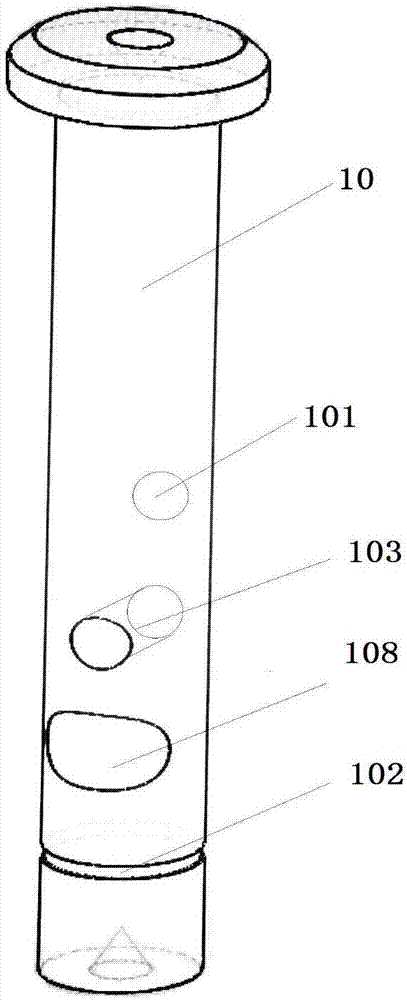

[0021] figure 1 A structural schematic diagram of a centrifugal swinging hinged rotor head according to an embodiment of the present invention. Such as figure 1 As shown, a kind of centrifugal swinging hinged rotor head provided by the present invention comprises rotor central axis 9, middle joint 1, swinging hinge 8, and transverse shaft 10 connected sequentially from inside to outside (in image 3 shown in ), swing hinge 5, paddle clamp 6; the swing hinge 8 and the paddle clamp 6 are connected by the horizontal shaft 10 arranged in the middle joint 1, and the paddle clamp 6 is connected with To install the paddle 12 (in Figure 4 shown in ), the pendulum hinge 5 is arranged between the oar clip 6 and the blade 12, the middle joint 1 defines the movable angle of the swing hinge 8, and the blade 12 rotates with the The swinging hinges 8 are on the same axis line, and the axis line where it is located is the axial direction of the rotor central axis 9 . The central axis of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com