Delivery mechanism and conveying device

A technology of conveying mechanism and conveying device, which is applied in the direction of conveyor, transportation and packaging to achieve the effect of reducing energy consumption, reducing rigidity and reducing energy loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

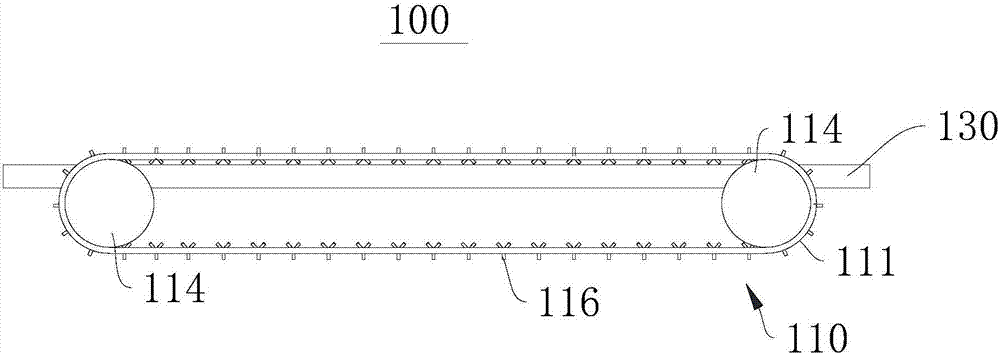

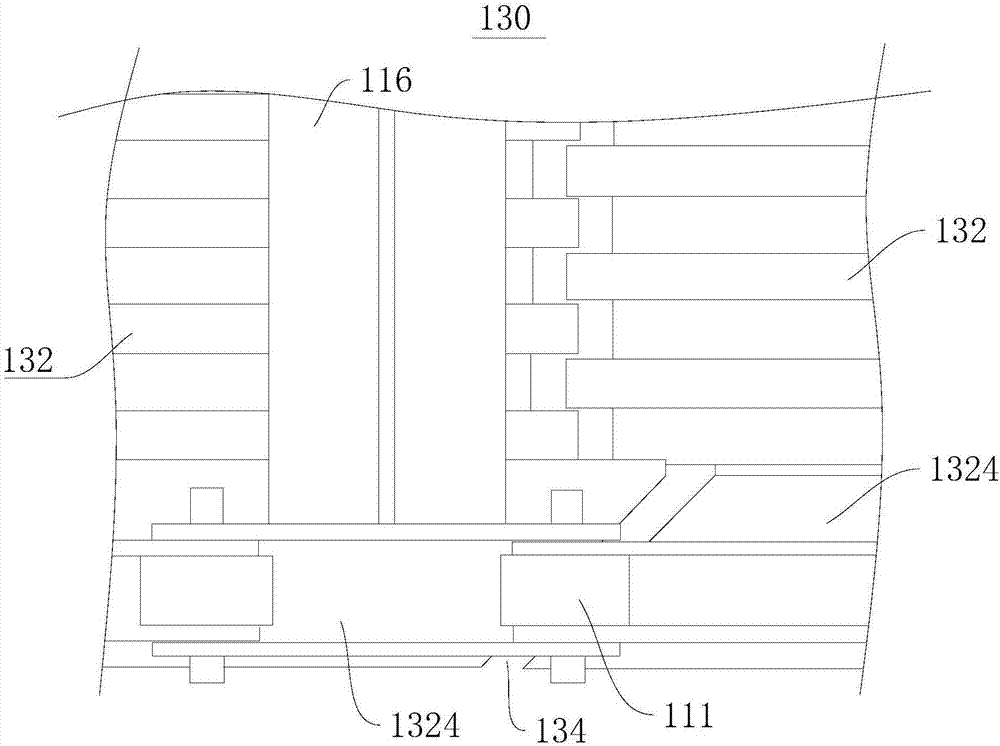

[0031] This embodiment provides a delivery device 100, please refer to figure 1 , this conveying device 100 includes a conveying mechanism 110 and a carrying plate 130 .

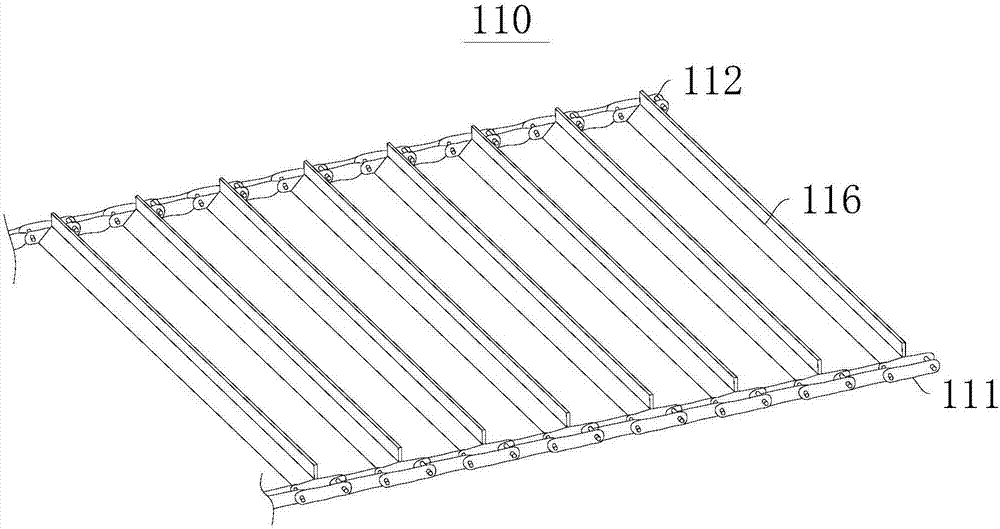

[0032] see figure 1 and figure 2 , the transmission mechanism 110 includes a first connecting part 111 , a second connecting part 112 , a driving part 114 and a plurality of pushing parts 116 .

[0033] Specifically, the first connecting part 111 and the second connecting part 112 are configured as chains, and the driving part 114 is a sprocket. The first connecting parts 111 are connected end to end to form a closed structure, and the second connecting parts 112 are connected end to end to form a closed structure.

[0034] There are two groups of driving parts 114, and each group of driving parts 114 includes a driving sprocket and a driven sprocket. The two sets of active components 114 cooperate with the first connecting component 111 and the second connecting component 112 respectively. The active ...

Embodiment 2

[0056] The structure of the conveying device 100 provided by the embodiment of the present invention is basically the same as that of the conveying device 100 in the first embodiment, the difference lies in that the raceway 1322 on the bearing unit 132 is formed differently.

[0057] see Figure 5 , in this embodiment, the carrying unit 132 includes a base plate 1325 and a plurality of limiting rods 1326 . The limiting rod 1326 is disposed on the base plate 1325 and fixedly connected with the base plate 1325 . The extending direction of the limiting plate is consistent with the extending direction of the first connecting member 111 .

[0058] A raceway 1322 is formed between two adjacent limiting rods 1326 .

[0059] Counting from the first connecting member 111 to the second connecting member 112, the odd-numbered raceways 1322 and the even-numbered raceways 1322 are alternately distributed in the length direction of the first connecting member 111, so that both ends of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com