Connecting structure of flange and guiding screening bars of papermaking-machine screening drum

A connection structure and paper machine technology, applied in the direction of textiles and papermaking, fiber raw material processing, etc., can solve the problems of small diversion angle of diversion surface, high maintenance cost, and inability to replace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

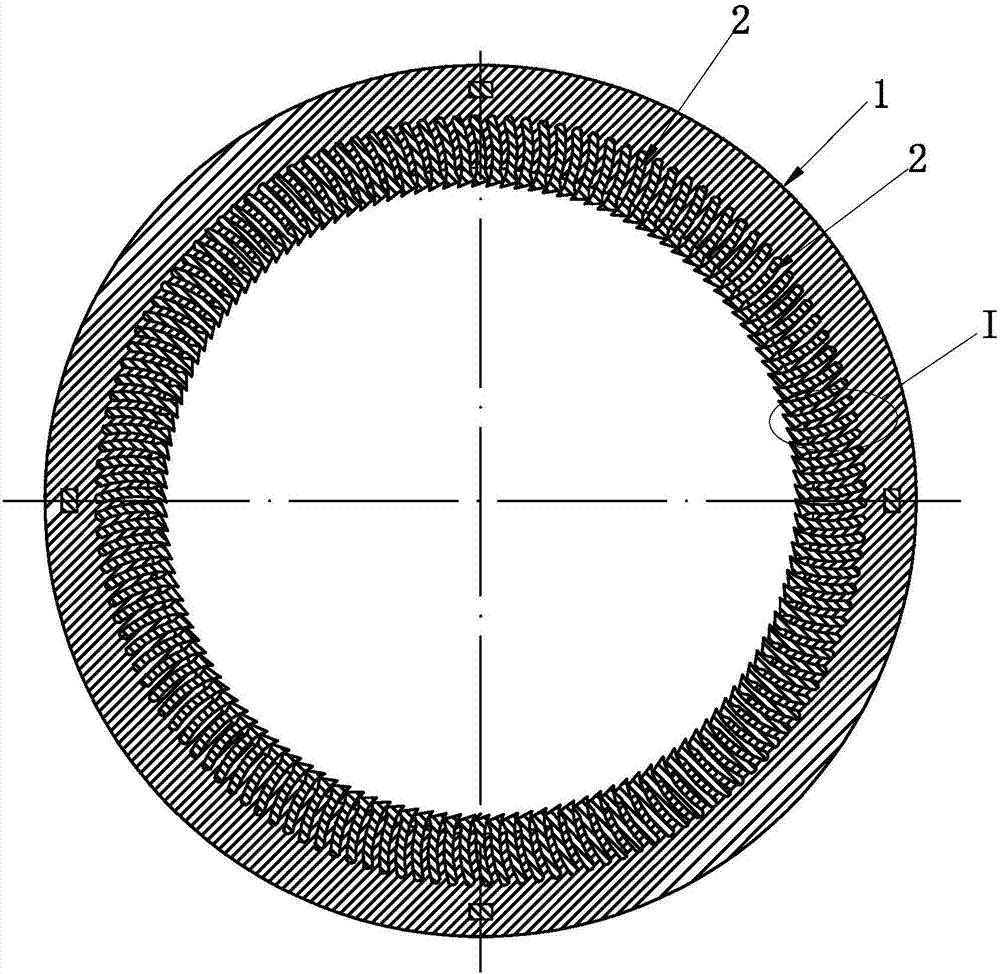

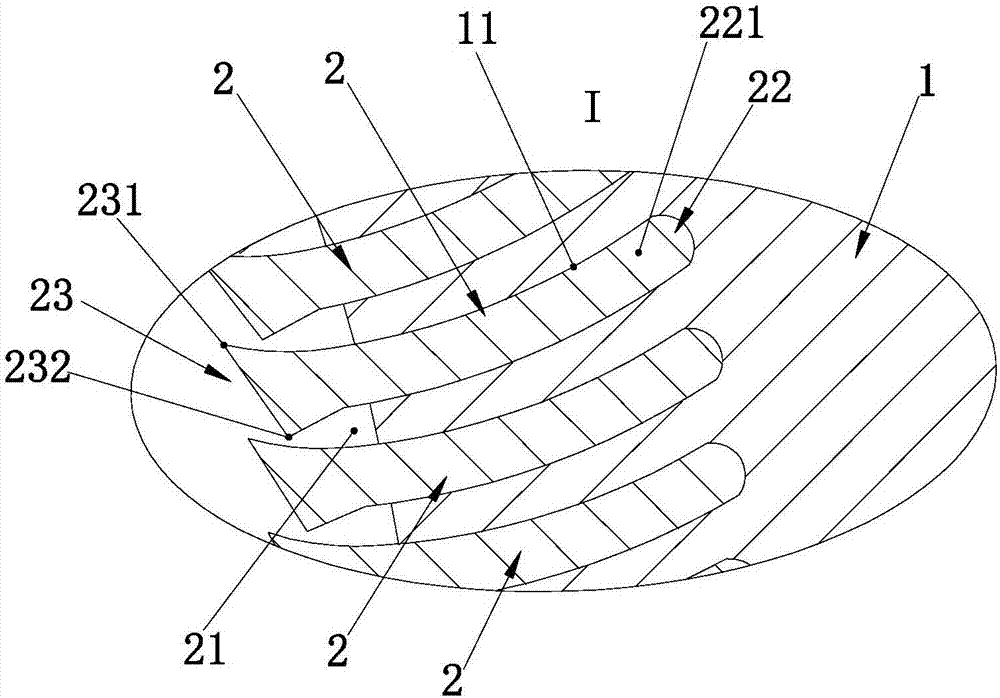

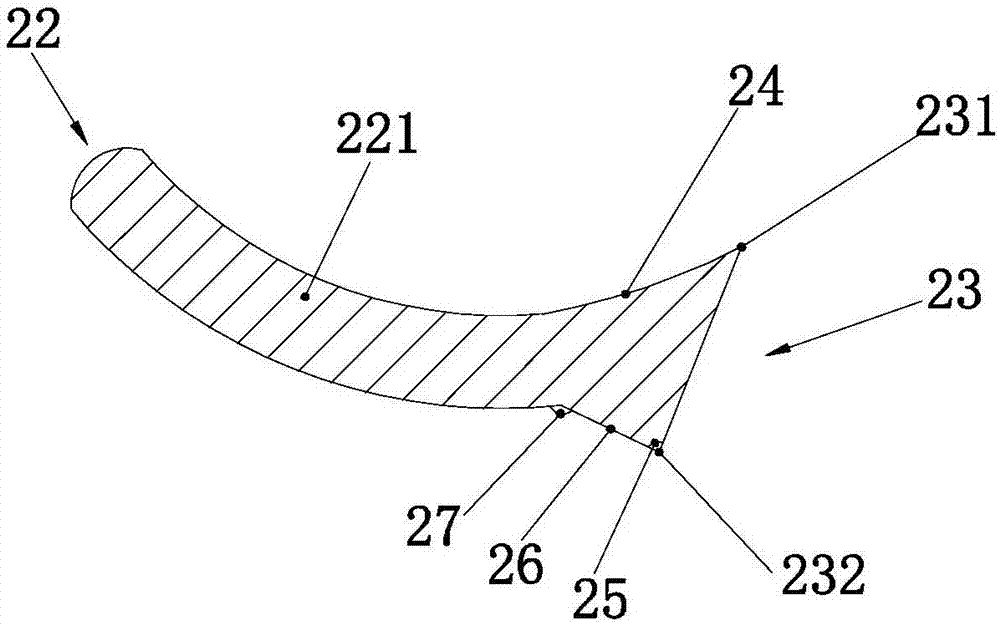

[0014] Such as figure 1 — image 3 The connecting structure of the flange plate of the screen drum of a paper machine and the guide screen rod shown includes a flange plate 1 and a number of guide screen rods 2 uniformly distributed along the contour of the flange plate 1. Each guide screen rod There is a screening gap 21 between them. The flange plate 1 is evenly distributed along its annular contour with insertion grooves 11 for the guide screen rods 2 to be inserted and arranged in the same direction. The guide screen rods 2 include and The insertion end 22 and the diversion end 23 inserted into the slot 11, the insertion end 22 is a body 221 that fits into the insertion slot 11, the diversion end 23 is an inclined surface, and the highest point 231 of the inclined surface is connected to an arc-shaped connecting surface 24 The main body 221 is connected, and its lowest point 232 is connected to the main body 221 through a connecting surface 26 having a first included angle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com