A method for alleviating the pressure pulsation hazard in the vaneless area of a Francis pump turbine

A water pump turbine, pressure pulsation technology, applied in hydropower, machines/engines, reaction engines, etc., can solve the problems of lack of understanding, less attention to pressure pulsation, unclear source and transmission mode, etc., to achieve operability Strong performance, simple and clear design method and steps, and the effect of reducing pressure fluctuations in the bladeless area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

[0011] The present invention proposes a method for alleviating the pressure pulsation hazard in the bladeless zone of the pump turbine, which includes the optimization of the following two aspects of the pump turbine:

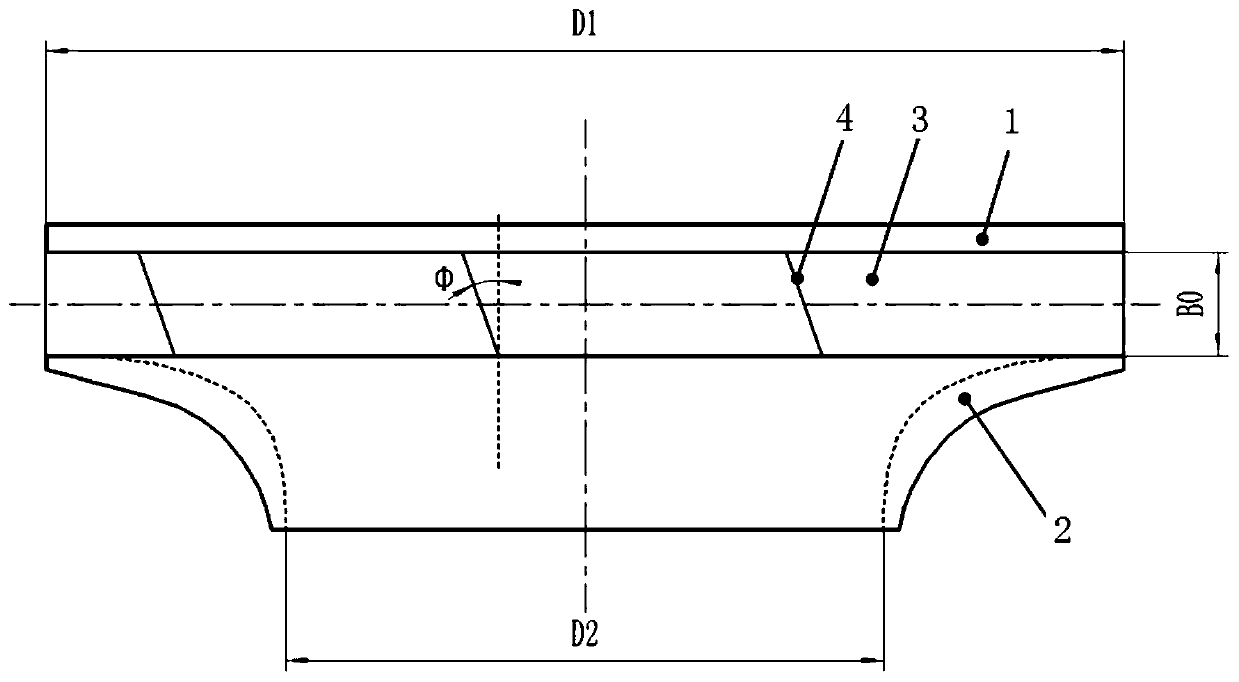

[0012] 1) if figure 1 As shown, the blade 3 on the high-pressure side of the runner of the Francis pump turbine (the water inlet side under the turbine working condition, and the water outlet side under the water pump working condition) is arranged obliquely, so that the included angle Φ between the water inlet side bone line 4 of the blade 3 and the axial direction is not less than 15° , its technical effect is to disperse the shedding vortex at the water inlet edge of turbine blades at different heights at different radial angles, so as to disperse the dynamic force of the shedding vortex on the top cover, so that each height layer i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com