A compressor wall surface treatment device with functions of expanding stability and eliminating noise

A processing device and compressor technology, which is applied to the components of the pumping device for elastic fluids, mechanical equipment, machines/engines, etc., can solve the problem of not involving the internal noise of the compressor, and achieve macroscopic orderly flow. , reducing losses, and the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

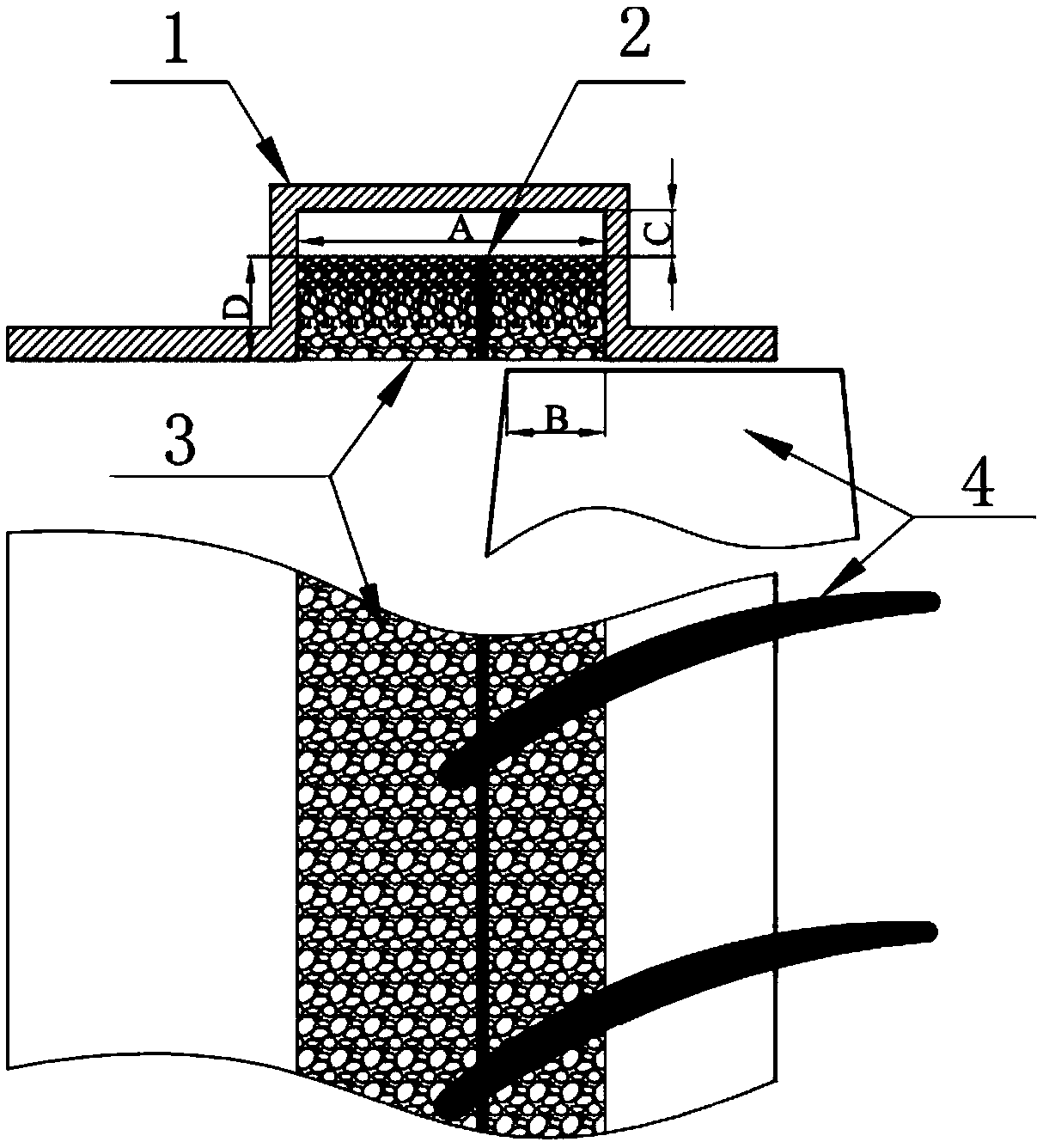

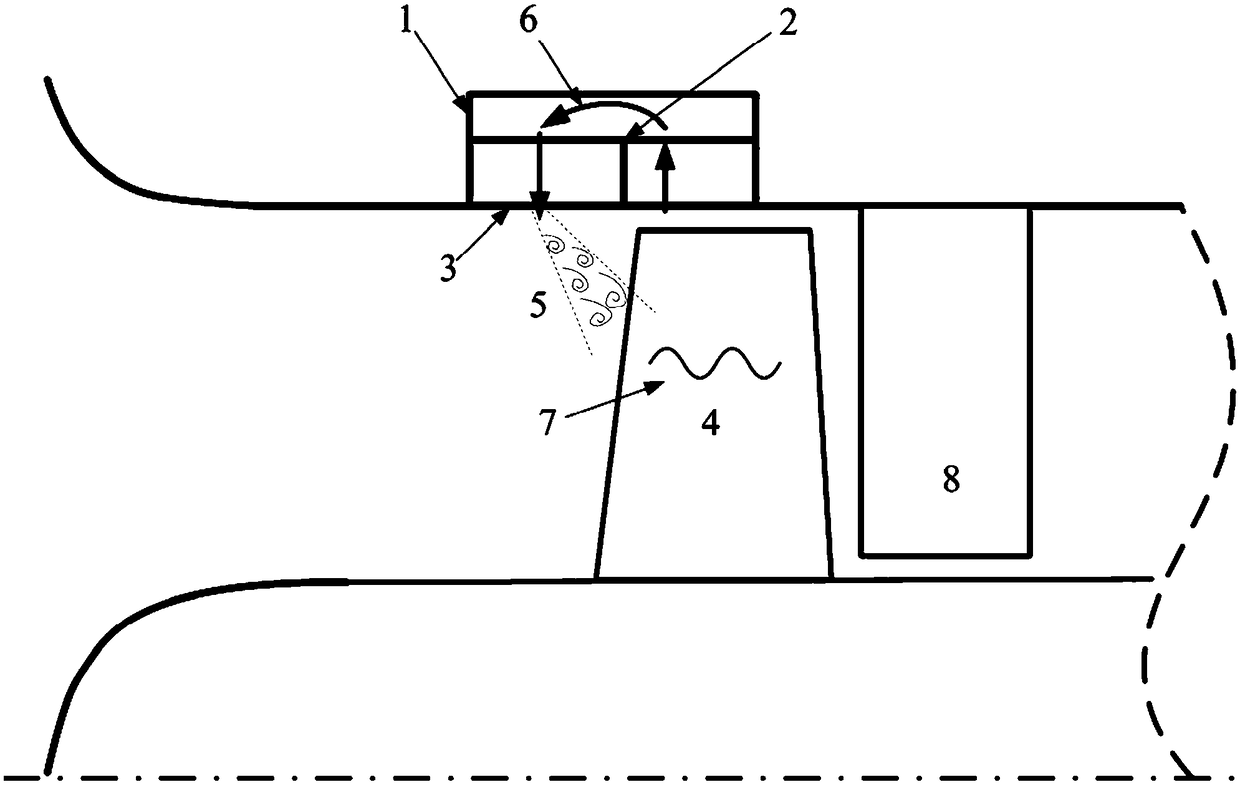

[0023] Attached below Figure 1-2 The compressor wall surface treatment device with the functions of expanding stability and silencing noise of the present invention will be described in detail.

[0024] Such as figure 1 As shown, the compressor wall treatment device with the functions of stabilizing and noise reduction includes an annular casing 1, an annular porous composite metal plate 3 and an annular rectifying plate 2; the annular porous composite metal plate 3 is composed of a multi-layer porous composite metal plate The annular casing 1 has an annular back cavity, and the annular porous composite metal plate 3 is placed in the annular back cavity; the annular rectifying plate 2 is embedded in the annular porous composite metal plate 3 . In this embodiment, the annular porous composite metal plate 3 is selected as an annular foam metal plate. The annular rectifying plate 2 extends along the thickness direction of the annular metal foam plate 3 , and the size of the an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com