Coaxial line planetary transmission gear ring output multi-gear speed change mechanism

A technology of planetary transmission and speed change mechanism, which is applied to transmission devices, gear transmission devices, mechanical equipment, etc., and can solve the problems of large volume, small variable speed range and low power of variable motors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

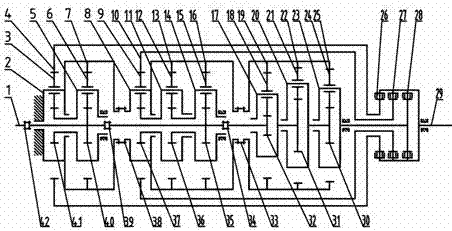

Embodiment 1

[0035] Embodiment 1: A three-gear planetary transmission shifting mechanism, the first gear, the second gear and the third gear are respectively: forward gear-forward gear-reverse gear. The first gear is composed of two-stage 2K-H (A) planetary transmission composed of planetary transmission type planetary mechanism, the second gear is composed of three-stage 2K-H(A) type planetary transmission type planetary mechanism, the third gear is composed of three-stage 2K-H(A) type planetary transmission The planetary mechanism includes an input shaft, a clutch, a sun gear, a planetary gear, a planetary carrier, and a ring gear. The planetary gear is arranged on the planetary carrier, and the sun gear is connected to the ring gear through the planetary gear.

[0036] The input shaft 1 is connected to the first-stage first-stage sun gear 40 through a connection pair 42, the first-stage first-stage sun gear 40 is connected to the first-stage first-stage planet 6, and the first-stage...

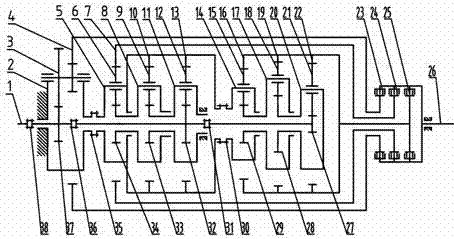

Embodiment 2

[0042] Embodiment 2: A three-gear planetary transmission shifting mechanism, the first gear, the second gear and the third gear are respectively: forward gear-forward gear-forward gear. The first gear is composed of a 2K-H(B) type planetary transmission type planetary mechanism, the second gear is composed of three-stage 2K-H(A) type planetary transmission type planetary mechanism, the third gear is composed of three-stage 2K-H(A) type planetary transmission The planetary mechanism includes an input shaft, a clutch, a sun gear, a planetary gear, a planetary carrier, and a ring gear. The planetary gear is arranged on the planetary carrier, and the sun gear is connected to the ring gear through the planetary gear.

[0043] The input shaft 1 is connected with the first gear first stage sun gear 37 through a connecting pair 38, the first gear first stage sun gear 37 is connected with a gear of the first gear first stage double planetary gear 3, the first gear The other gear o...

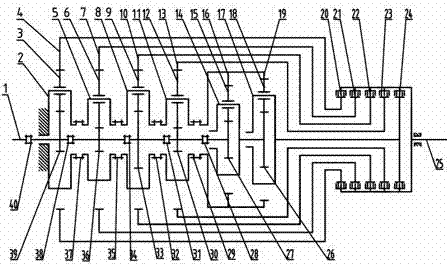

Embodiment 3

[0046] Embodiment 3: A five-gear planetary transmission shifting mechanism, the first gear, second gear, third gear, fourth gear and fifth gear are respectively: forward gear - forward gear - forward gear - - Forward gear - Reverse gear. The first gear, the second gear, the third gear, and the fourth gear are composed of one-stage 2K-H(A) planetary transmission. Type planetary mechanism, the fifth gear is composed of two-stage 2K-H(A) type planetary transmission The planetary mechanism includes an input shaft, a clutch, a sun gear, a planetary gear, a planetary carrier, and a ring gear. The planetary gear is arranged on the planetary carrier, and the sun gear is connected to the ring gear through the planetary gear.

[0047] The input shaft 1 is connected with the first-stage first-stage sun gear 39 through the connection pair 40, the first-stage first-stage sun gear 39 is connected with the first-stage first-stage planetary gear 3, and the first-stage first-stage planetary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com