Two-degree-of-freedom piezoelectric driver for bending piezoelectric vibrator and excitation method for two-degree-of-freedom motion realized by using the driver

A piezoelectric driver and piezoelectric vibrator technology, which can be applied to piezoelectric effect/electrostrictive or magnetostrictive motors, generators/motors, electrical components, etc., and can solve the problems of high cost, small stroke, and complex structure. , to achieve the effect of low cost, large driving stroke and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

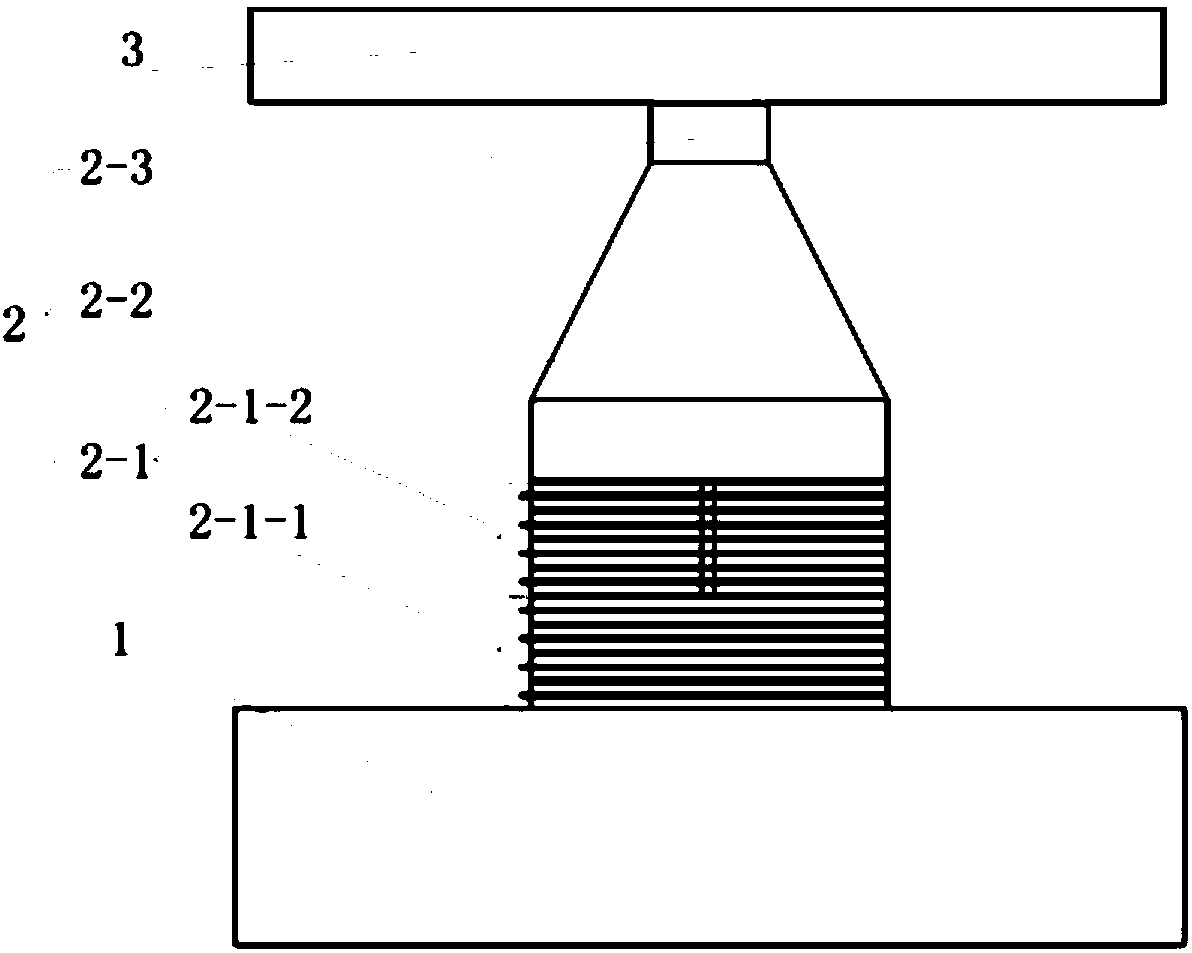

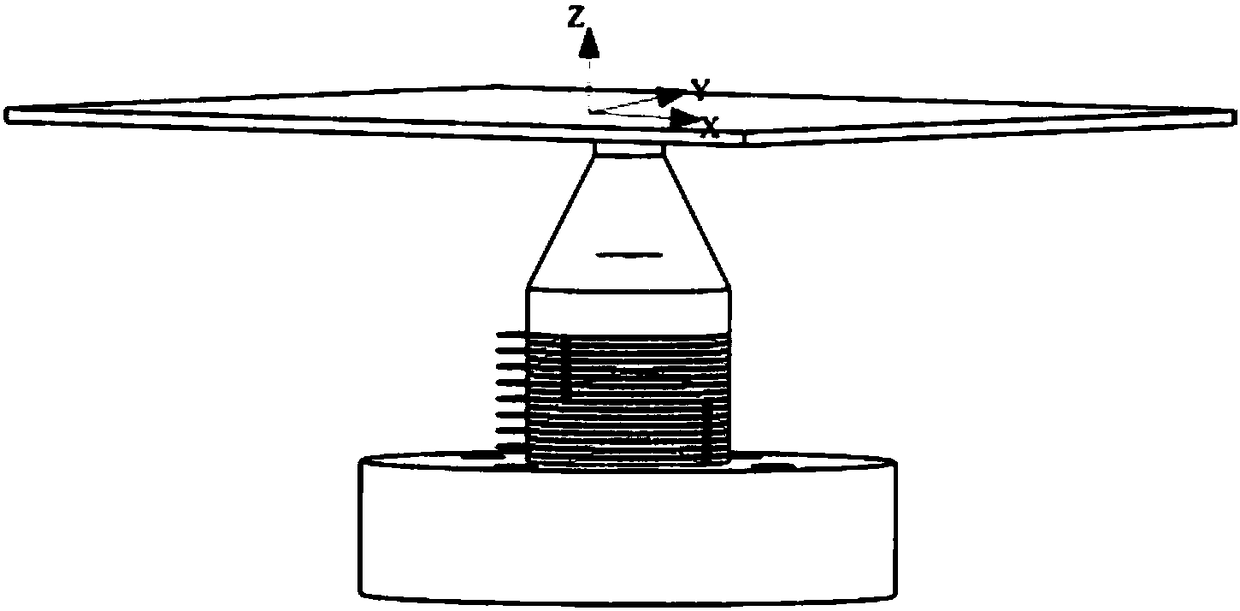

[0046] Specific embodiment one: see Figure 1 to Figure 5 To explain this embodiment, the two-degree-of-freedom piezoelectric actuator of the bending piezoelectric vibrator described in this embodiment includes a base 1, a piezoelectric vibrator 2 and a mover 3;

[0047] The piezoelectric vibrator 2 includes a bent piezoelectric ceramic group 2-1, an horn 2-2, and a driving foot 2-3. The bent piezoelectric ceramic group 2-1 is disposed between the base 1 and the horn 2-2. Meanwhile, the thin end of the horn 2-2 is provided with a driving foot 2-3, and the driving foot 2-3 is in contact with the mover 3;

[0048] The bending piezoelectric ceramic group 2-1 is divided into two parts, namely the first bending piezoelectric ceramic group 2-1-1 and the second bending piezoelectric ceramic group 2-1-2.

[0049] In this embodiment, the two-degree-of-freedom piezoelectric actuator adopting the bending piezoelectric vibrator of the present invention has low cost and large driving stroke. In ...

specific Embodiment approach 2

[0050] Specific implementation manner two: see Figure 1 to Figure 5 To explain this embodiment, the difference between this embodiment and the two-degree-of-freedom piezoelectric actuator of the bending piezoelectric vibrator described in the first embodiment is that the mover 3 is a cylindrical mover, a spherical mover or a flat type. Mover.

specific Embodiment approach 3

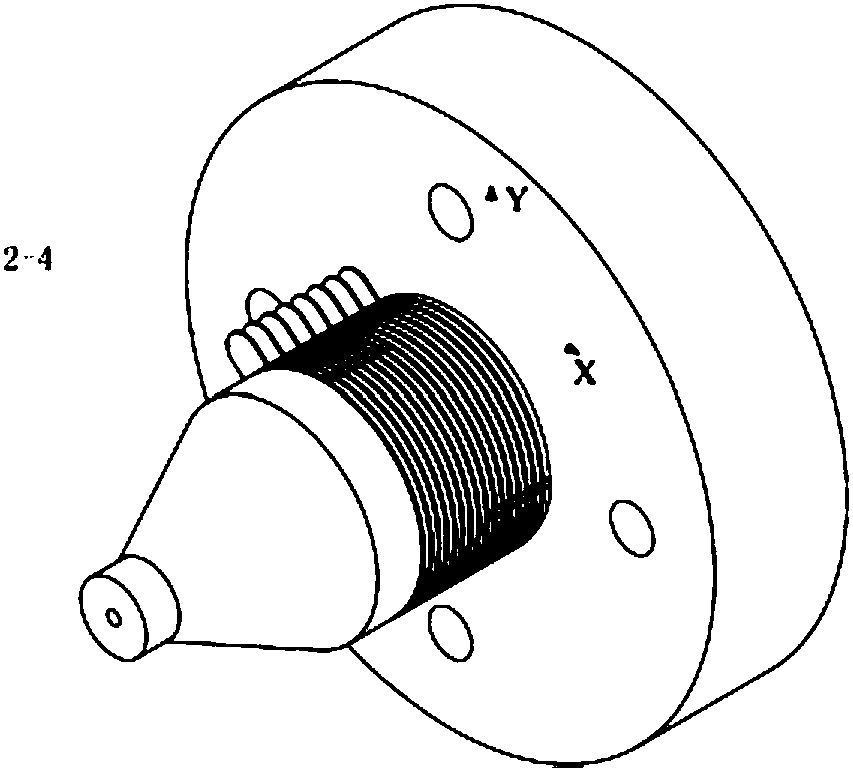

[0051] Specific implementation manner three: see Figure 1 to Figure 5 To illustrate this embodiment, the difference between this embodiment and the two-degree-of-freedom piezoelectric actuator of the bending piezoelectric vibrator described in the first embodiment is that the first group of bending piezoelectric ceramic group 2-1-1 and the second A energized electrode sheet 2-4 is provided between two adjacent piezoelectric ceramic sheets in the group bending piezoelectric ceramic group 2-1-2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com