A recycled paper roll machine

A paper rolling machine and turning machine technology, which is applied in the direction of winding strips, thin material handling, transportation and packaging, can solve the problems of high price, affecting the rolling process, and easy sagging of paper, so as to improve stability and improve slippage. The effect of moving stability and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

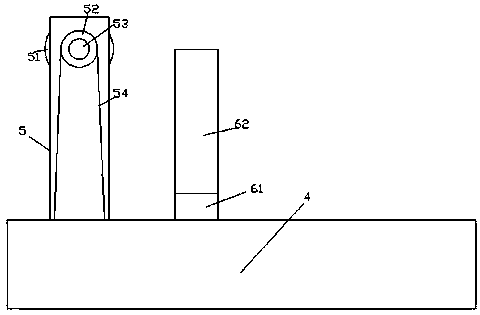

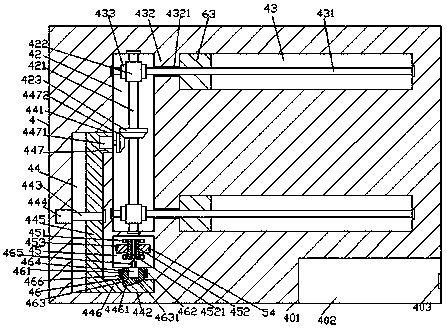

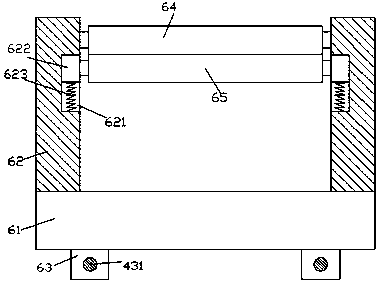

[0022] Such as Figure 1-Figure 5 As shown, a recycled paper roll machine according to the present invention includes a base 4 and a roll holder 5 fixed on the top left side of the base 4, and the inside of the left side of the base 4 is provided with a first Cavity 42, the base 4 on the right side of the first cavity 42 is provided with guide grooves 43 that are symmetrical up and down and stretched left and right, and the left end of each guide groove 43 is connected to the first A partition plate 432 is provided between the right sides of the cavity portion 42, and a through hole 4321 is provided in each partition plate 432, and a through hole 4321 is provided in each of the through hole 4321 to extend to the left and right sides. The first helical rod 431, the left end of the first helical rod 431 stretches into the first cavity 42 and is connected with the left inner wall of the first cavity 42 by screwing. The right end of the helical rod 431 extends into the guide groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com