an injection mold

An injection mold and movable mold technology, which is applied in the field of injection molding tools for plastic products, can solve the problems of weak sliding stability of the side core slider, affecting the service life of the side core pulling mechanism, etc., so as to improve the sliding stability, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

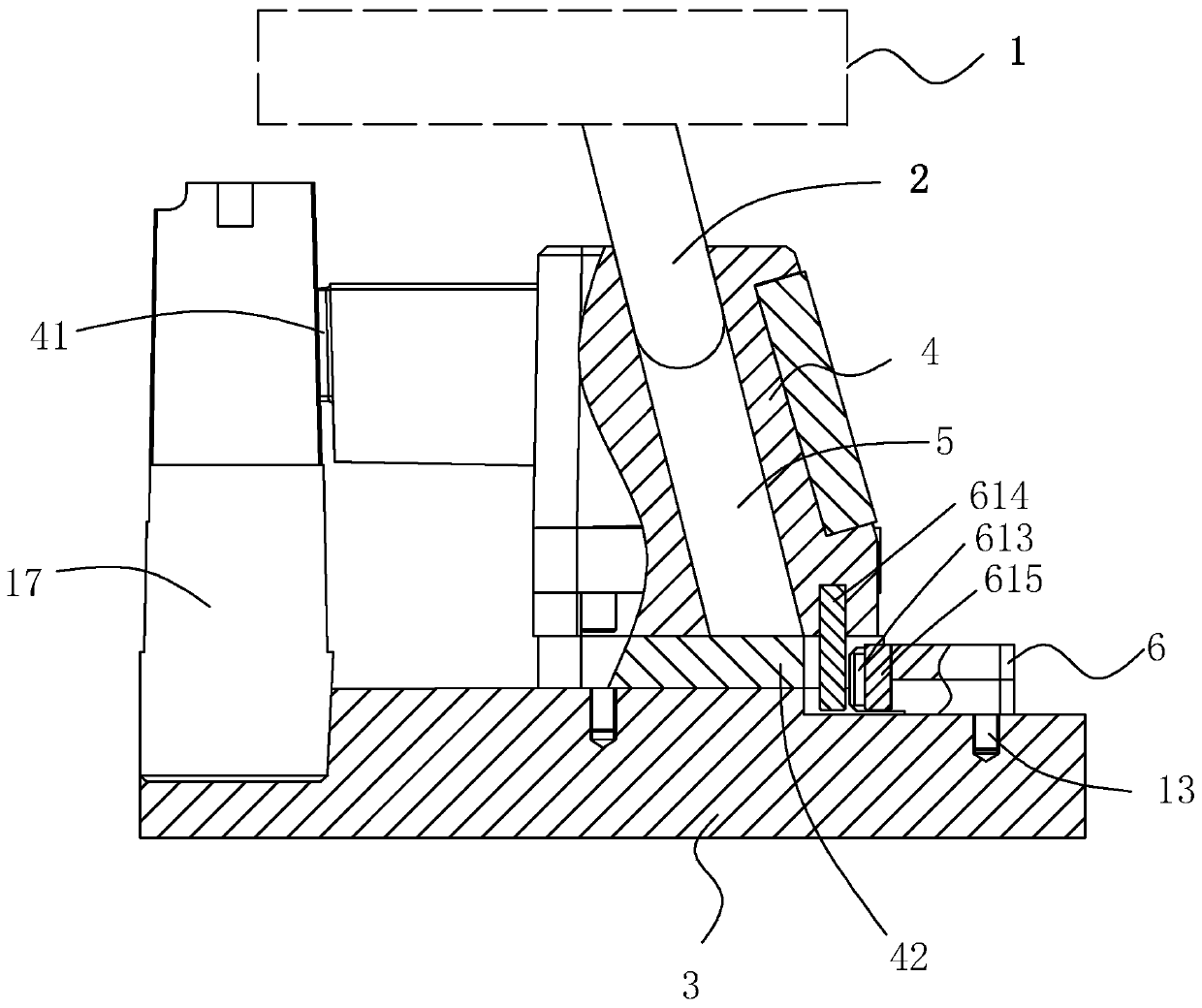

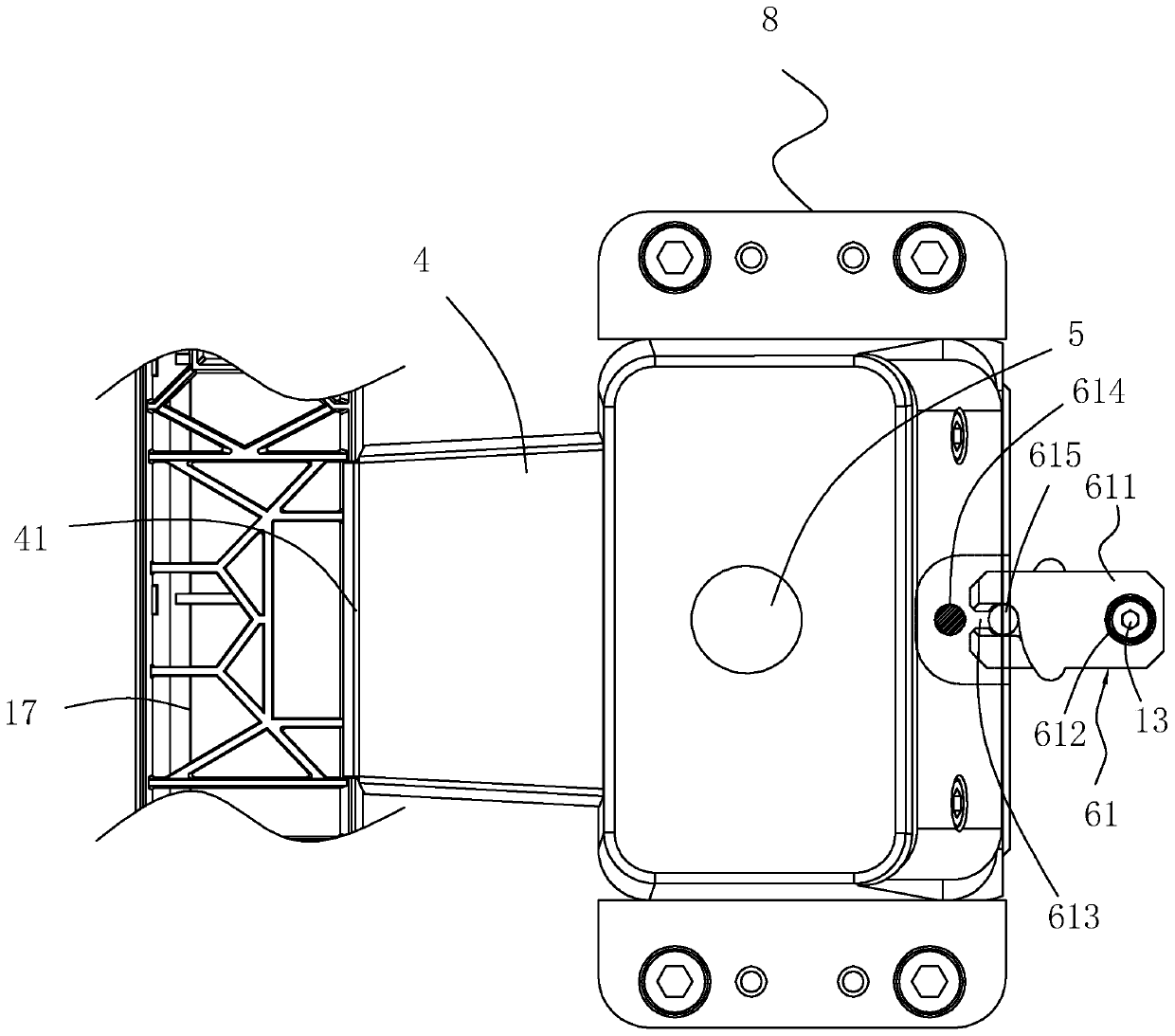

[0034] A side-drawing limit mechanism, see figure 1 , including the first installation platform 1 and the second installation platform 3, the first installation platform 1 and the second installation platform 3 can be separated or approached each other, the first installation platform 1 is connected with a slanted guide column 2, and the second installation platform The side core slide block 4 is connected with sliding on the side of mounting platform 3, and side core sliding block 4 is provided with oblique guide hole 5, is used for forming the molding end 41 of plastic product 17 mounting holes; When the first mounting platform 1 When approaching or moving away from the second installation table 3 , the inclined guide post 2 is inserted into the inclined guide hole 5 to drive the entire side core slider 4 to slide back and forth along the second installation table 3 .

[0035] see figure 1 as well as figure 2 , on the side of the side core slide block 4 away from the formin...

Embodiment 2

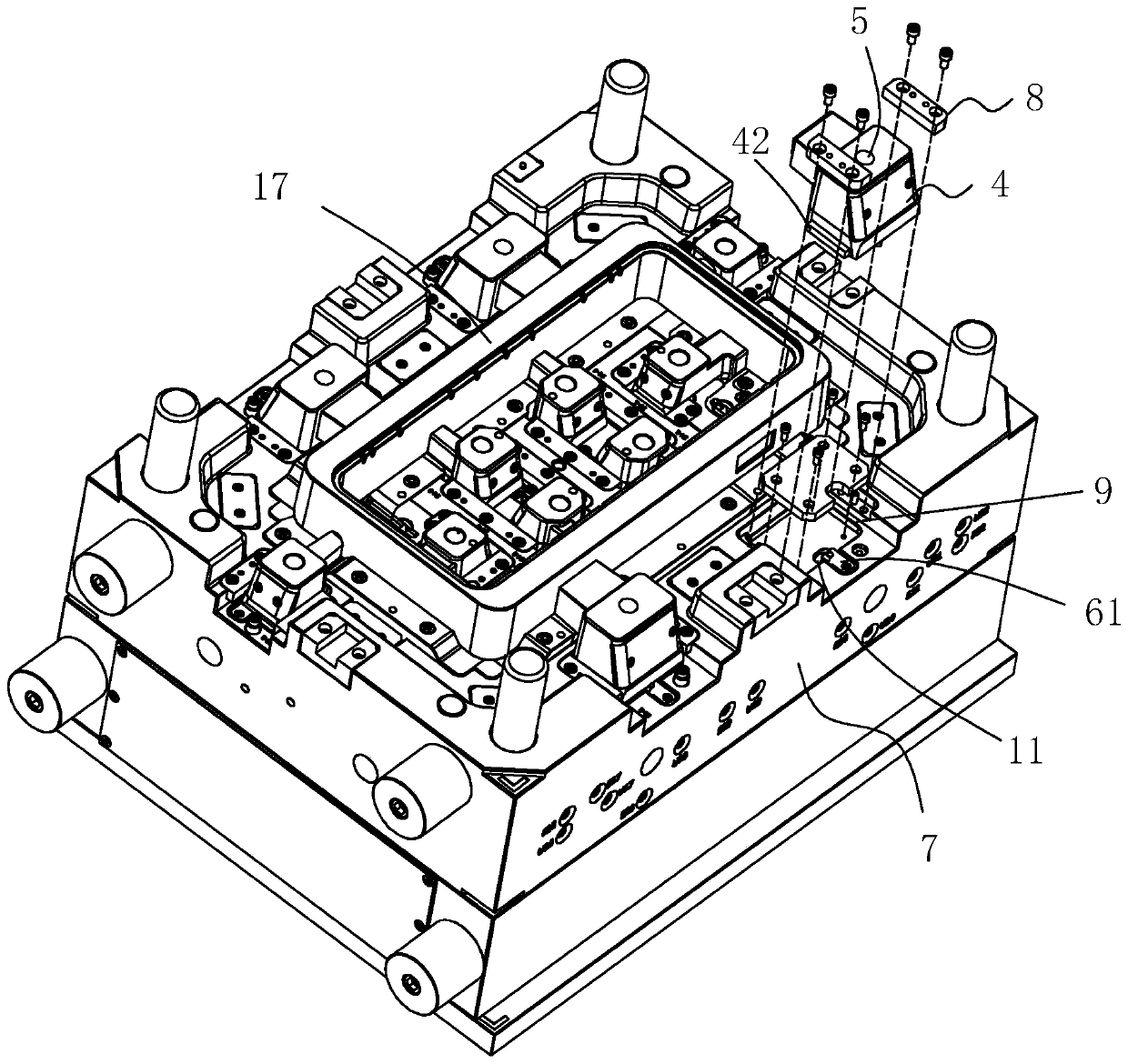

[0041] An injection mold, see figure 1 as well as image 3 , including a movable mold 7, a fixed mold, and a side-drawing limit mechanism as in Embodiment 1. The second mounting table 3 in Embodiment 1 is a movable mold 7, and the first mounting table 1 is a fixed mold, and the side-drawing limit mechanism Mechanism is installed on the moving mold 7.

[0042] Specifically, see image 3 as well as Figure 5 , the parting surface of the movable mold 7 is provided with a first installation groove 9, a pressure plate 8 is installed on the groove wall of the second installation groove 11, and a chute 10 is formed between the pressure plate 8 and the groove bottom of the first installation groove 9, and the side profile The core slider 4 is provided with a sliding block 42. When the side core slider 4 is located in the first installation groove 9, the sliding block 42 cooperates with the chute 10, and the entire side core slider 4 can move along the first installation groove 9. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com