Collar of retractable arches and retractable arches

A shrinkable arch technology, which is applied in the field of card and retractable arch, can solve the problems of weak strength at the lap joint, slip resistance of the retractable arch, and large bending of the card, so as to improve the strength and rigidity , Sliding stability is improved, and the effect of optimizing the force condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

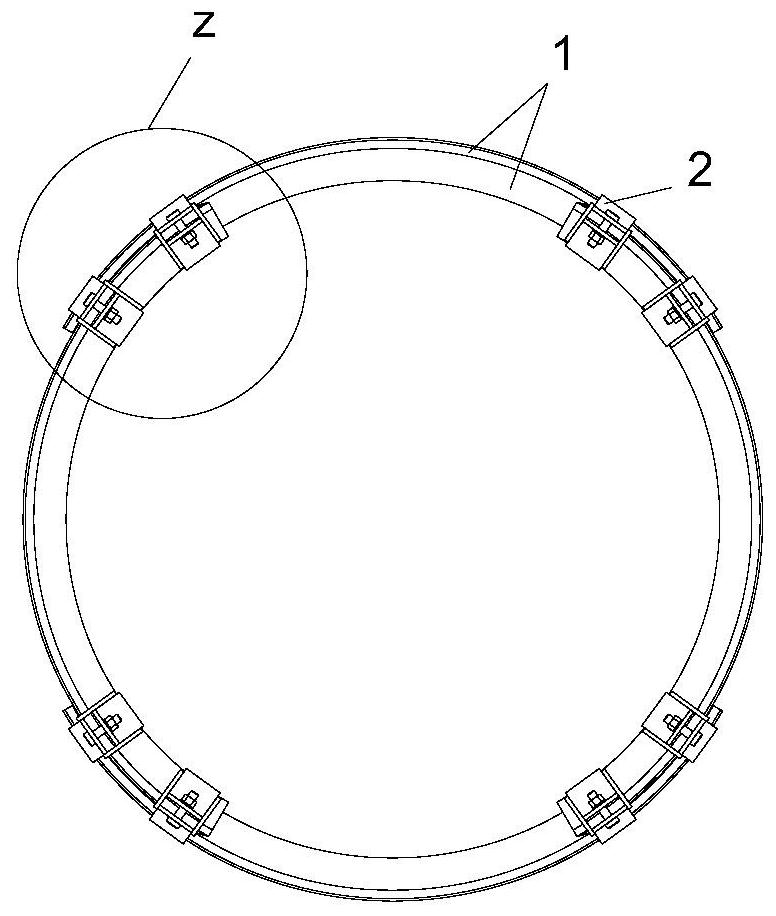

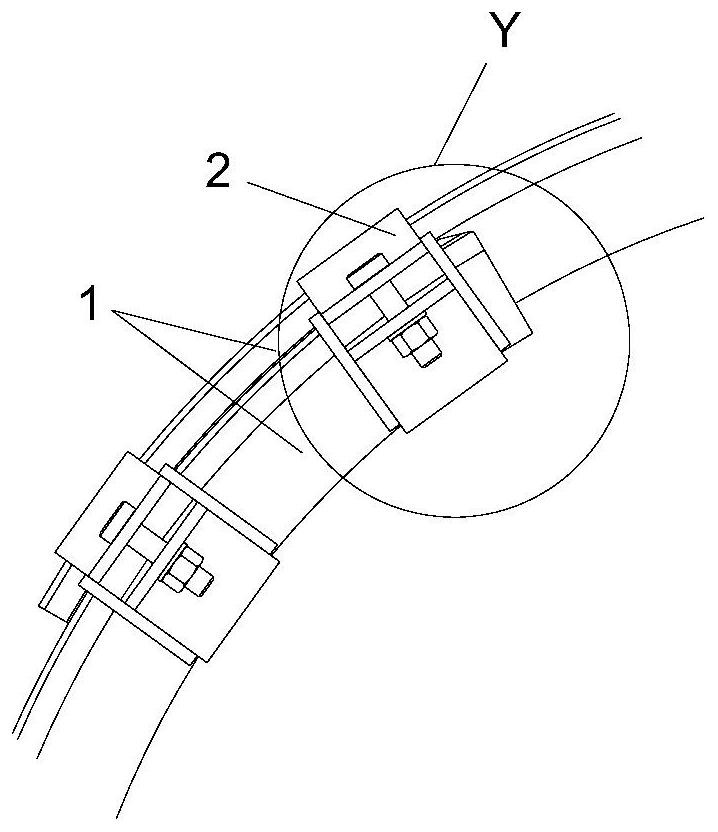

[0022] Such as Figure 1 to Figure 4 The shrinkable arch frame of the present invention as shown includes several sections of U-shaped steel 1 overlapping up and down, and the two sections of U-shaped steel 1 are clamped and fitted by clamps 2 at the overlapping section of the two sections of U-shaped steel 1 .

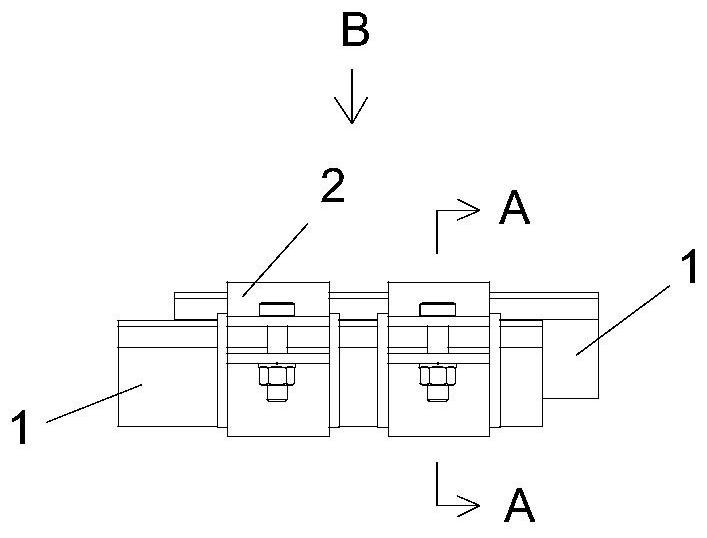

[0023] Such as Figure 3 to Figure 6 As shown, the clamp 2 has an upper clamping plate 21 and a lower clamping plate 25 which are detachably connected. The clamping width of the upper clamping plate 21 is adapted to the upper opening width of the U-shaped steel 1 in the retractable arch, and the clamping width of the lower clamping plate 25 is adapted to the section width of the U-shaped steel 1 in the retractable arch. The lower end of the side of the upper clamping plate 21 is provided with upper clamping plate ears extending to both sides, and the upper end of the side of the lower clamping plate 25 is also provided with lower clamping plate ears extending to both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com