An oxygen-absorbing film based on tea polyphenol-β-cyclodextrin inclusion compound and its preparation method

A technology of cyclodextrin inclusion compound and tea polyphenols, which is applied in the field of food packaging materials, can solve the problems of low oxygen absorption capacity, decreased mechanical strength of packaging materials, insufficient oxygen absorption performance, etc., and achieve the effect of ensuring oxygen absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

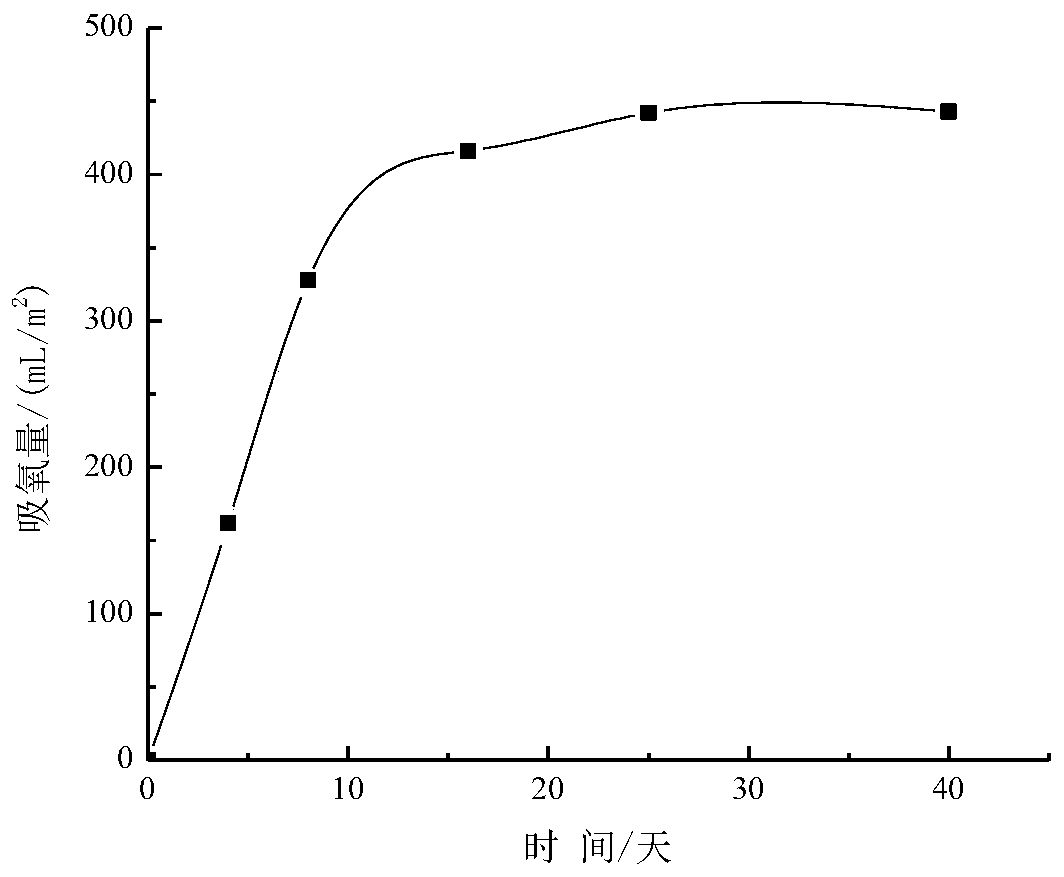

Embodiment 1

[0034] (1) Dissolve 10.6g of β-cyclodextrin in water, then dissolve 8.5g of tea polyphenols and 3.2g of citric acid in absolute ethanol, and add dropwise to the aqueous solution of β-cyclodextrin under constant stirring.

[0035] (2) The mixed solution was stirred at 50° C. for 4 hours, cooled to room temperature after the end, and placed in a refrigerator until the white powder precipitated at the bottom of the Erlenmeyer flask no longer increased. Vacuum filtration was carried out with a circulating vacuum pump. During the suction filtration, it was quickly washed with water and absolute ethanol successively to obtain a white powder, which was placed in a vacuum drying dish to dry and stored for future use.

[0036] (3) Weigh 40g of oxygen absorbing agent and 460g of LDPE masterbatch, mix them uniformly in a mixer, add them into the hopper of an extruder, melt, extrude and cut to obtain pellets of suitable size and uniform thickness.

[0037] (4) Add the obtained pellets to ...

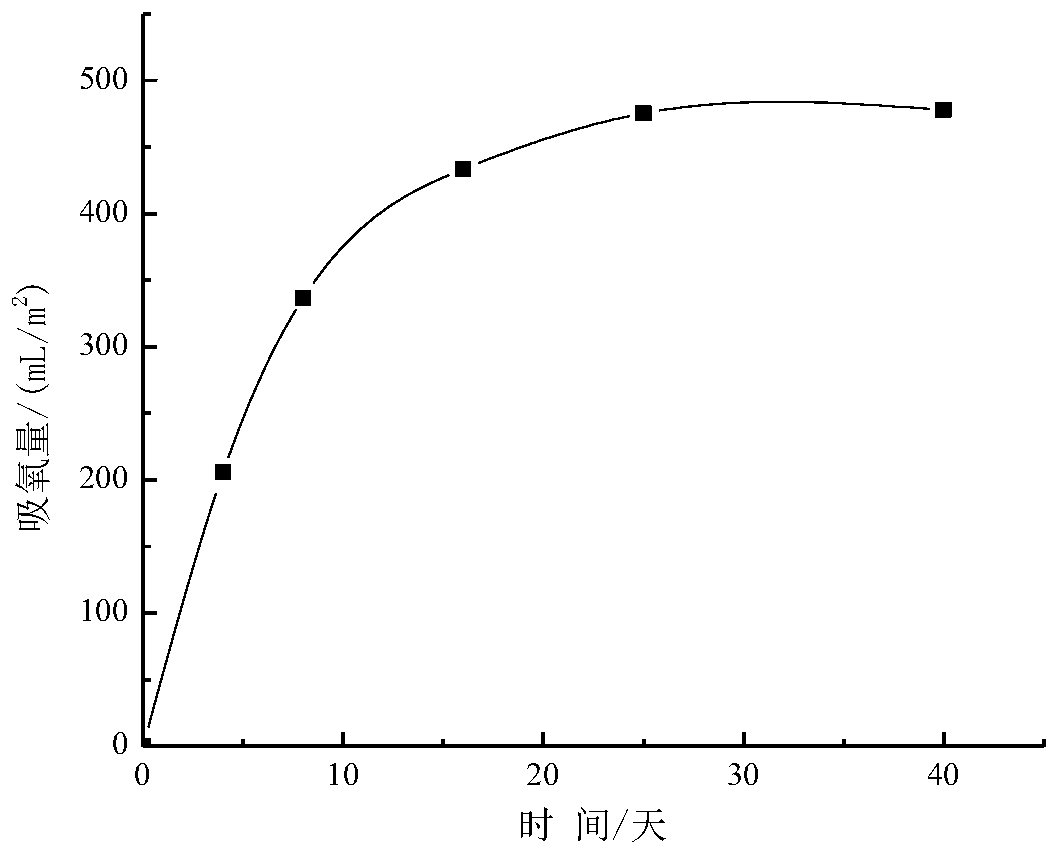

Embodiment 2

[0039] (1) Dissolve 6.8g of β-cyclodextrin in water and heat to dissolve. Then 9.4g of tea polyphenols and 1.3g of citric acid were dissolved in absolute ethanol, and were added dropwise into the aqueous solution of β-cyclodextrin under continuous stirring.

[0040](2) The mixed solution was stirred at 50° C. for 4 hours, cooled to room temperature after the end, and placed in a refrigerator until the white powder precipitated at the bottom of the Erlenmeyer flask no longer increased. Vacuum filtration was carried out with a circulating vacuum pump. During the suction filtration, it was quickly washed with water and absolute ethanol successively to obtain a white powder, which was placed in a vacuum drying dish to dry and stored for future use.

[0041] (3) Weigh 10g of oxygen absorbing agent and 490g of LDPE masterbatch, mix them uniformly in a mixer, add them into the hopper of an extruder, melt, extrude and cut to obtain pellets of suitable size and uniform thickness.

[0...

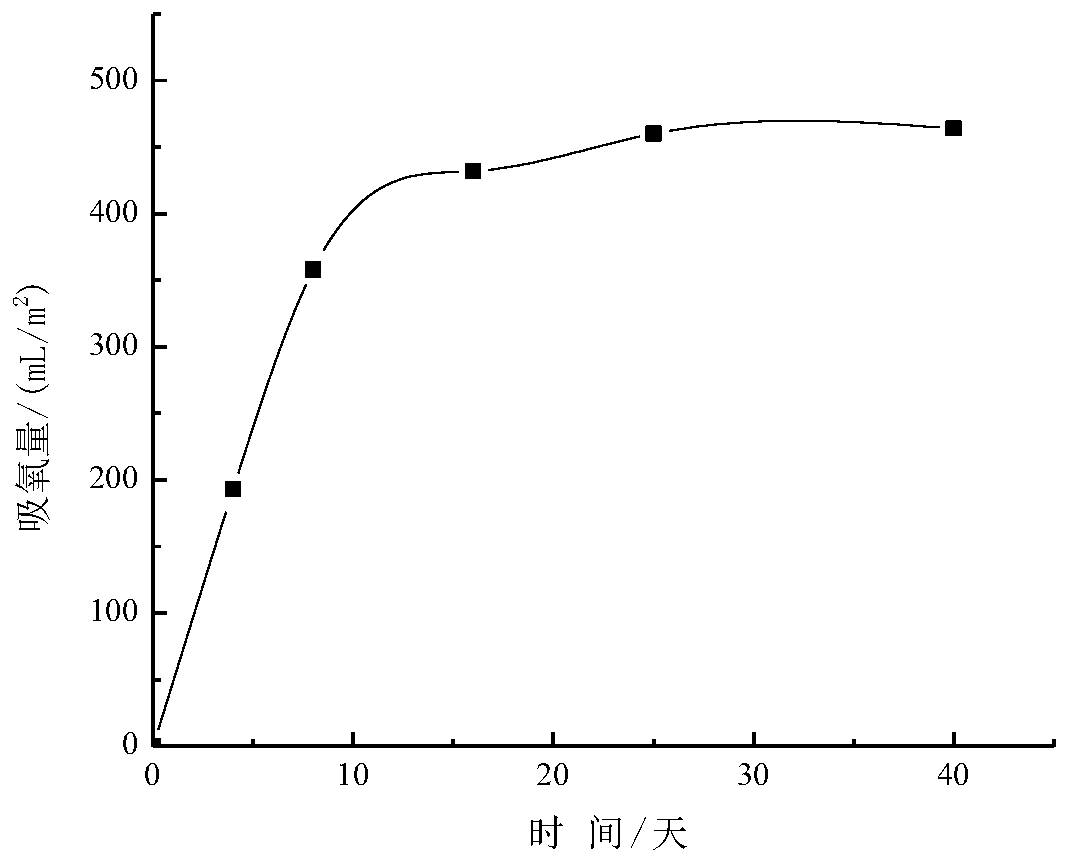

Embodiment 3

[0044] (1) Dissolve 8.2g of β-cyclodextrin in water and heat to dissolve. Then 12.6g of tea polyphenols and 0.36g of citric acid were dissolved in absolute ethanol, and were added dropwise into the aqueous solution of β-cyclodextrin under continuous stirring.

[0045] (2) The mixed solution was stirred at 50° C. for 4 hours, cooled to room temperature after the end, and placed in a refrigerator until the white powder precipitated at the bottom of the Erlenmeyer flask no longer increased. Vacuum filtration was carried out with a circulating vacuum pump. During the suction filtration, it was quickly washed with water and absolute ethanol successively to obtain a white powder, which was placed in a vacuum drying dish to dry and stored for future use.

[0046] (3) Weigh 25g of oxygen absorbing agent and 475g of LDPE masterbatch, mix them uniformly in a mixer, add them into the hopper of an extruder, melt, extrude and cut to obtain pellets of suitable size and uniform thickness.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com