Package structure and OLED (organic light emitting diode) device packaged by adopting same

A packaging structure, packaging cover technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

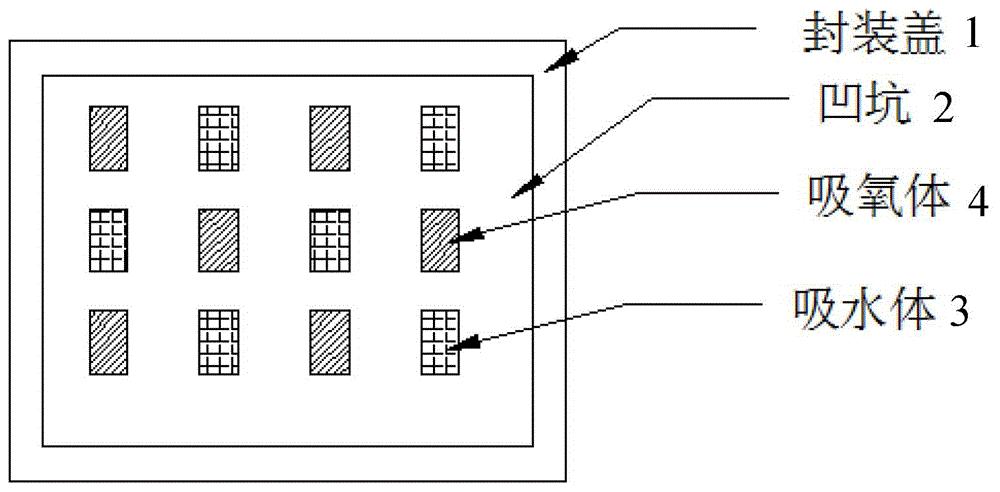

[0024] The present invention provides a packaging structure, including a packaging cover, the inner surface of the packaging cover has pits, the area of the pits completely covers the effective light-emitting area of the screen, and an OLED packaging area is arranged around the pits, such as using UV glue The screen body and the package cover are packaged, and the width of the package area is 0.5-2mm. A water absorbing body and an oxygen absorbing body are respectively arranged in the pits, the main component of the water absorbing body is a water absorbing agent, and the main component of the oxygen absorbing body is an oxygen absorbing agent. The function of the water absorbing agent is to absorb water vapor in the external environment of the OLED, and the function of the oxygen absorbing agent is to absorb oxygen in the external environment of the OLED. The oxygen absorbing agent and the water absorbing agent can be arranged in a matrix in the pit, or pasted or coated in...

Embodiment 2

[0040] The water absorbing body and oxygen absorbing body can also choose gel-like water absorbing agents and oxygen absorbing agents to achieve the encapsulation effect. The main component of the water absorbing body with the water absorbing effect is metal oxides, such as calcium oxide. The main components of the oxygen absorption effect are alkali metals and alkaline earth metals, molecular sieves or active metals. The specific setting method is as follows:

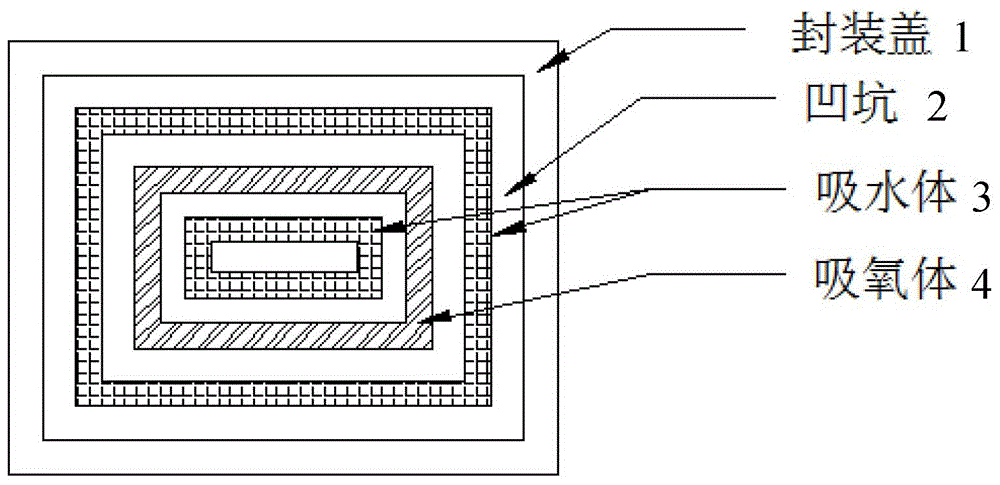

[0041] Way 2, such as figure 2 :

[0042] The water absorbing body 3 or the oxygen absorbing body 4 is dotted in the recess 2 of the packaging cover 1 in the form of glue, and the shape can be a closed shape that is sleeved at intervals (such as figure 2 Shown).

[0043] In order to achieve the encapsulation effect, the following restrictions are now made on the water absorbent and oxygen absorbent

[0044] 1. The thickness of the water absorbing body and the oxygen absorbing body is 0.05-0.5mm, this embodiment is 0.5mm;

[...

Embodiment 3

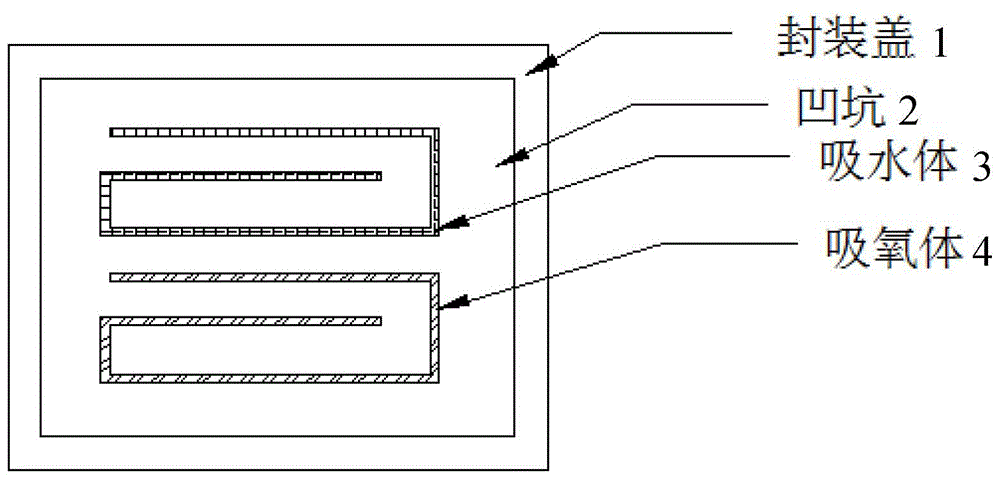

[0050] The water absorbing body 3 or the oxygen absorbing body 4 is dotted in the recess 2 of the package cover 1 in the form of glue, and each forms an independent semi-closed shape (such as image 3 Shown).

[0051] In order to achieve the encapsulation effect, the following restrictions are now made on the water absorbent and oxygen absorbent

[0052] 1. The thickness of the water absorbing body and the oxygen absorbing body is between 0.05-0.5mm, and this embodiment is 0.5mm;

[0053] 2. The total area of the water absorbing body and the oxygen absorbing body accounts for more than 30% of the effective light-emitting area, the total surface area of this embodiment accounts for 40% of the effective light-emitting area, and the area ratio of the water absorbing body and the oxygen absorbing body is 5:1;

[0054] 3. The water absorbing body and the oxygen absorbing body are distributed in the pits in a line manner, and are arranged at intervals, and the distance between adjacent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com