Cutterhead frequency conversion control cabinet armature torque get-out-of-trap system and method for shield tunneling machine

A frequency conversion control cabinet and cutter head torque technology, which is applied in earthwork drilling, mining equipment, tunnels, etc., can solve the problem that the cutter head cannot rotate, and achieve the effect of improving the success rate of getting out of trouble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with accompanying drawing, and these accompanying drawings are all simplified schematic diagrams, only illustrate the basic structure of the present invention in a schematic way, and the direction of this specific implementation is based on figure 1 Orientation is standard.

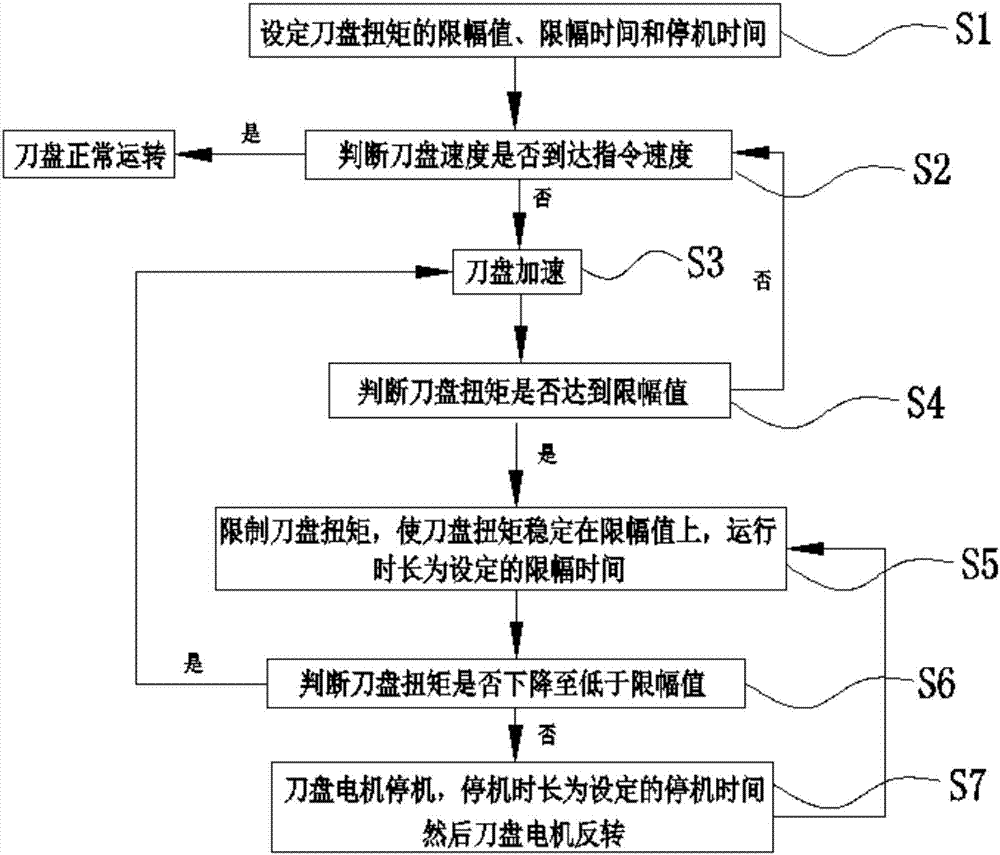

[0026] Such as figure 1 As shown, a kind of cutterhead escape method for shield machine of the present invention comprises the following steps:

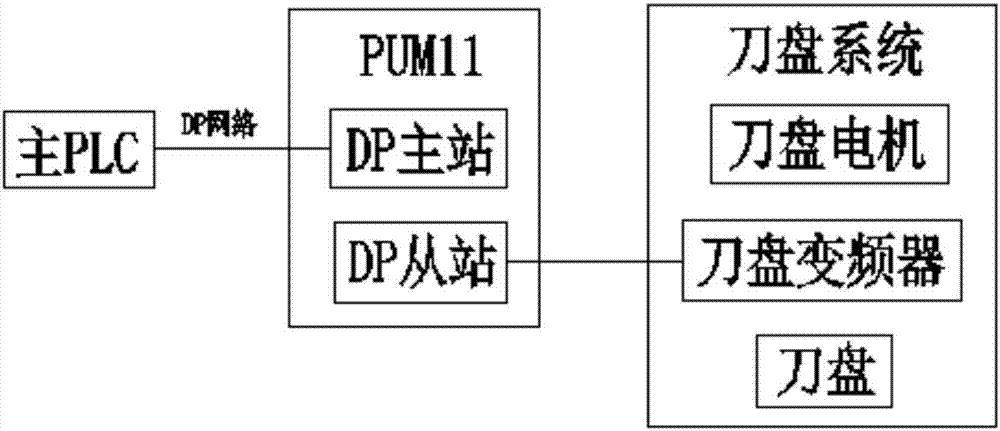

[0027] S1. Set the limit value of the cutterhead torque (usually set to 120% of the rated torque of the motor), the limit time and the downtime, and the main PLC will pass the limit value, limit time and downtime of the cutterhead torque through the DP The network is transmitted to the DP slave station (PF612) of PUM11, and after being processed by PUM11, the limit value, limit time and stop time of the inverter can be modified in real time through the DP master station (PF612...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com