Screws and screw connections for components made of foam plastic

A screw connection and screw technology, which is applied in the direction of connecting components, screws, thin plate connections, etc., can solve the problems of screw entrance rupture, screw loss of retention, high screw screw-in torque, etc., and achieve the effect of avoiding cracking or cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

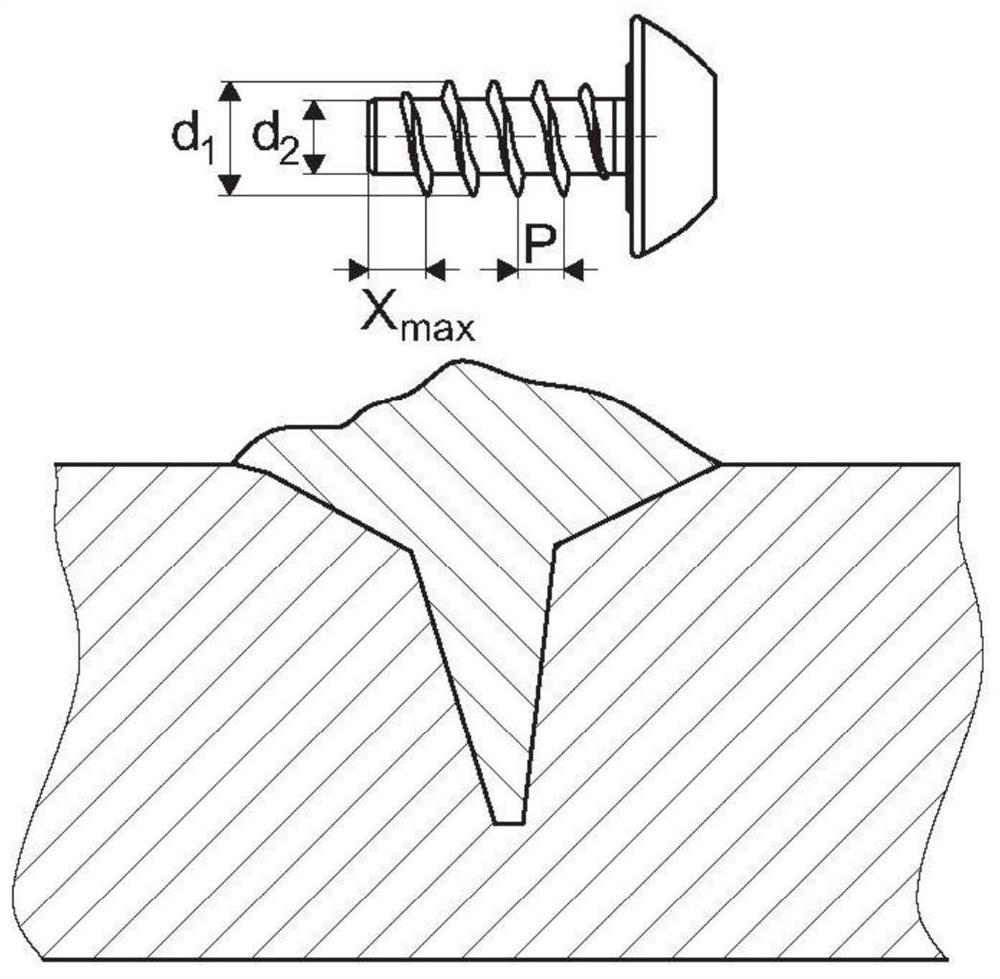

[0072] figure 1 A side view showing a section through a prior art plastic tube 4 of dense injection molded material with conventional thread rolled screws. When used in plastics, the known sharp-edged screws have the disadvantage of damaging the screwed-in plastic by breaking the screw opening or by stress cracking. At the same time, a relatively high torque is required to drive the screw.

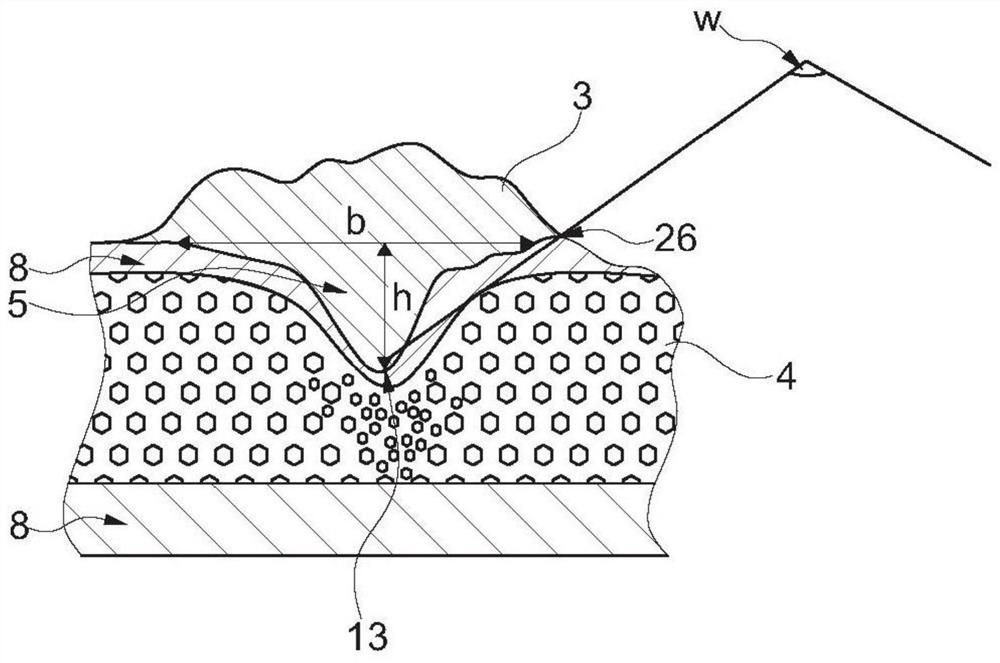

[0073] In screw connections using MuCell injection molded parts, the compression layer is damaged by such screws, as a result, conventional screws completely lose their holding effect in the residue of the foam layer and can hardly be tightened in the second pass.

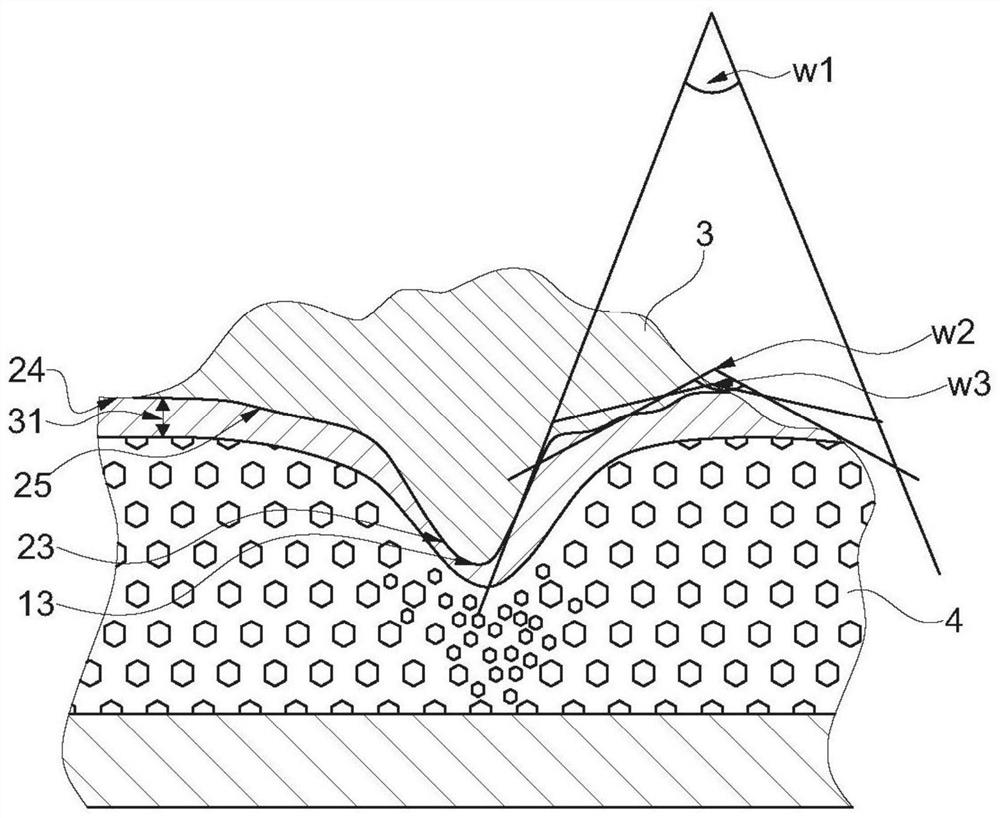

[0074] figure 2 A side view showing a section through a plastic tube 4 manufactured using a MuCell or other similar process with a screw 3 according to the invention. The outer shape of the screw 3 may be conical. Typically, the screw diameter measures 4, 4.5, 5, 5.5 or 6 mm and the screw length is 12 to 20 mm.

[0075] T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com