Bio-based high-barrier multilayer co-extruded blown film

A high-barrier, multi-layer co-extrusion technology, applied in the direction of layered products, synthetic resin layered products, chemical instruments and methods, etc., can solve the problems of simple structure and insufficient degradation, and achieve low cost, short degradation time and Speed controllable, cost-effective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

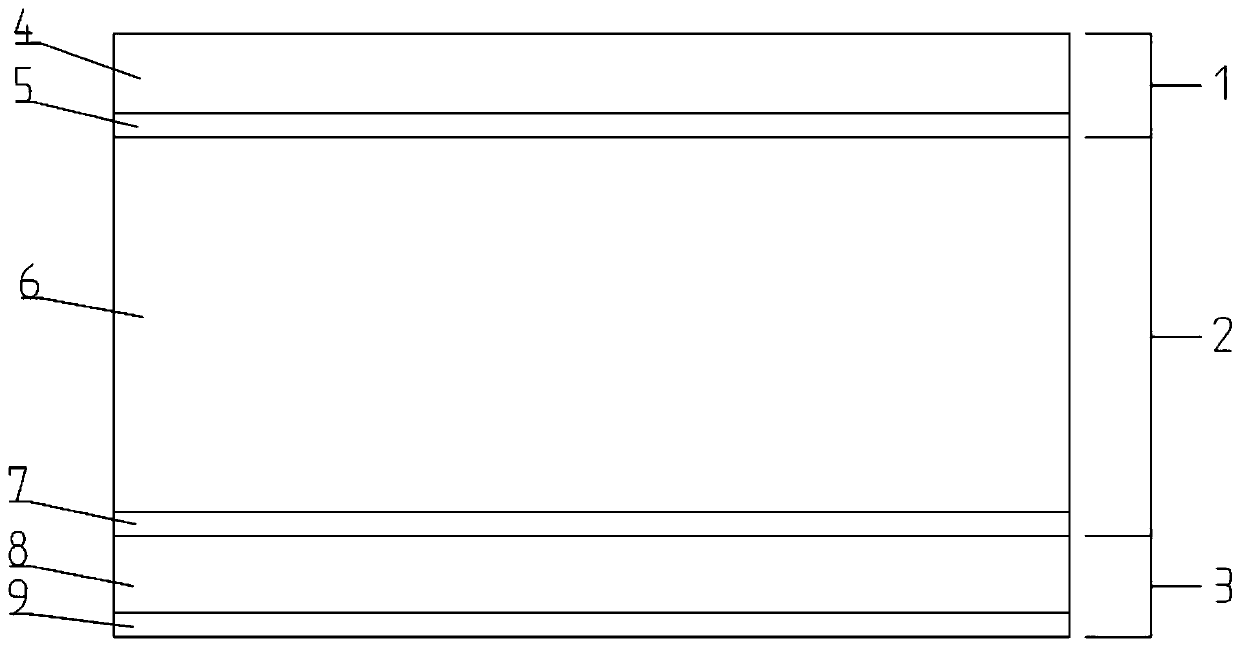

[0025] A bio-based high-barrier multi-layer co-extruded bio-based blown film, comprising a surface layer 1, a middle layer 2, and an inner layer 3;

[0026] The surface layer 1 includes a surface resin layer 4, a surface additive layer 5, the surface additive layer 5 is located below the surface resin layer 4, the surface resin layer 4 is a six-fold controllable degradation (LCSZ) resin, and the surface additive layer 5 is an environmentally controllable degradation ( HJZJ) additives;

[0027] The middle layer 2 includes a middle resin layer 6 and a middle additive layer 7. The middle additive layer 7 is located below the middle resin layer 6, the middle resin layer 6 is modified polypropylene carbonate (SHQ-MPC) resin, and the middle additive layer 7 is oxidized. Bio-based controllable degradation (YSZJ) additives;

[0028] The inner layer 3 includes an inner resin layer 8 and an inner additive layer 9. The inner additive layer 9 is located below the inner resin layer 8. The inner ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com