Self-healing microcapsule and preparation method thereof, paint, coating and epoxy resin composite material

A self-healing microcapsule, epoxy resin technology, applied in epoxy resin coatings, microcapsule preparations, microsphere preparation and other directions, can solve the problems of slow pH adjustment and complex process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

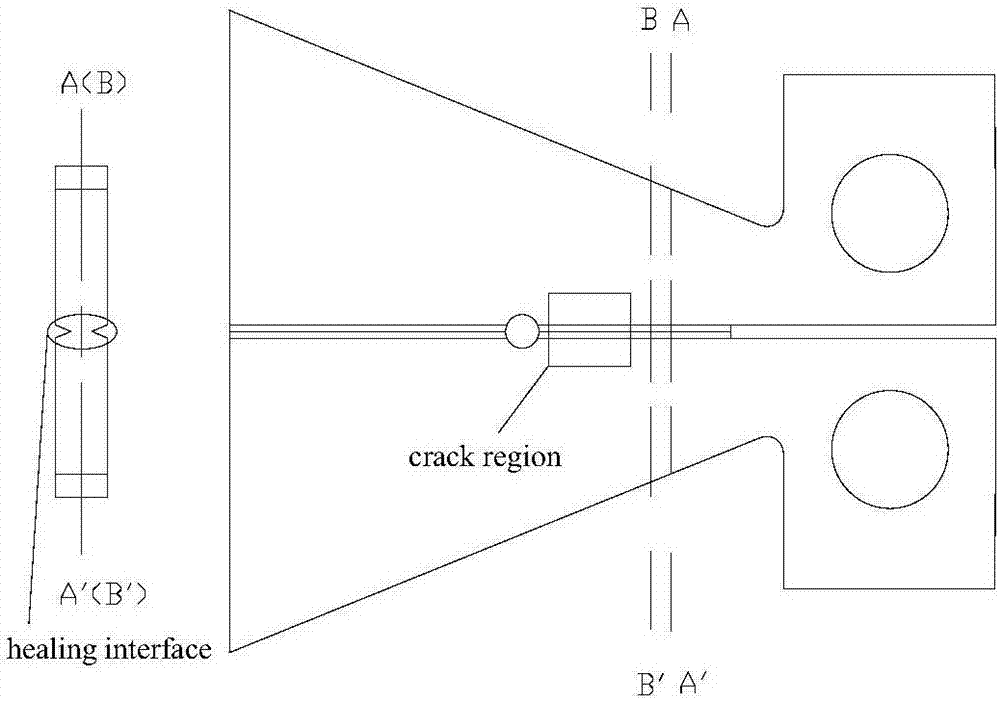

[0040] In view of the current situation that polymer composite materials in the prior art are prone to cracks under the influence of external force and environment, the embodiment of the present invention discloses a preparation method of self-healing microcapsules, which includes the following steps:

[0041] A), emulsifier, urea, formaldehyde, reaction accelerator, ethyl phenylacetate are mixed with water, emulsified, and emulsion is obtained;

[0042] B), heating and reacting the emulsion to obtain self-healing microcapsules.

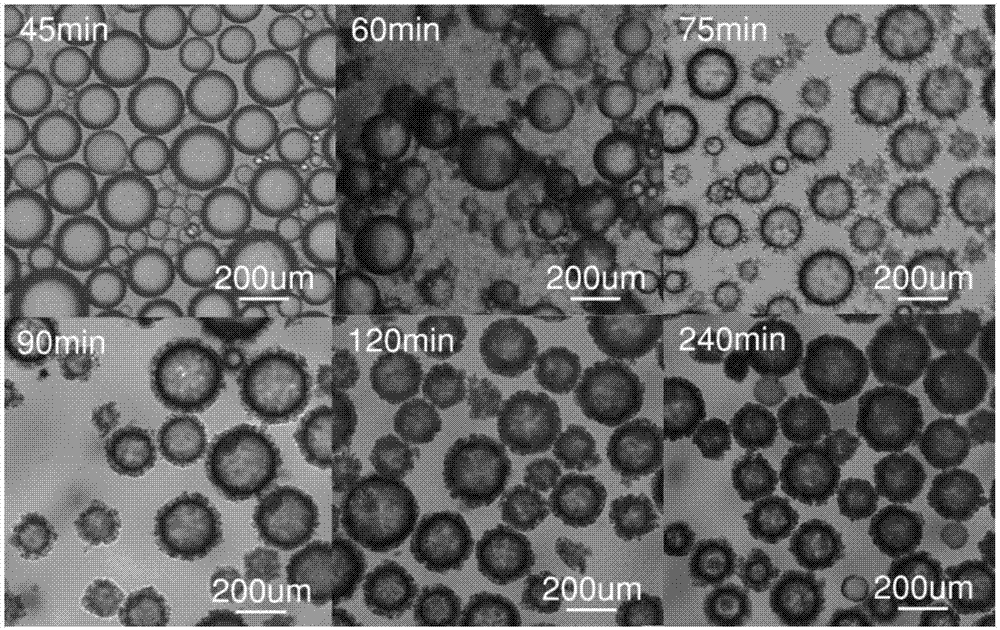

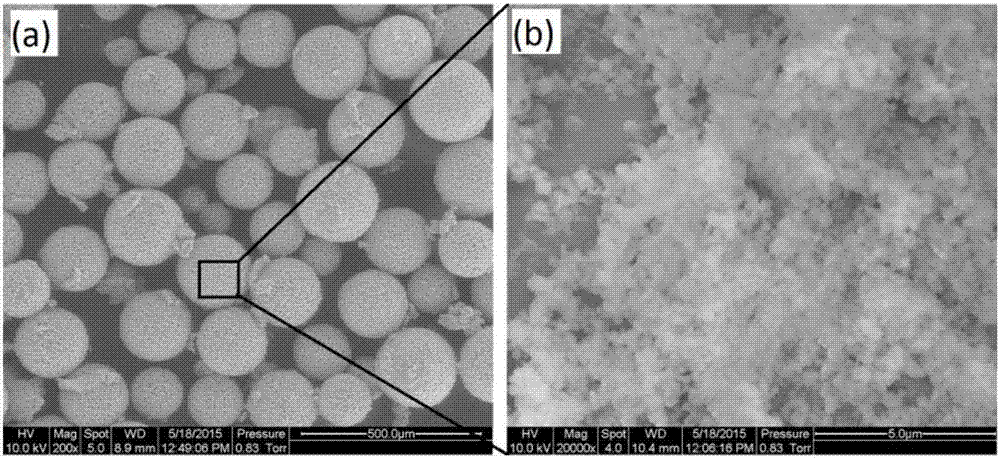

[0043] This application adopts a one-step method to in-situ synthesize urea-formaldehyde resin self-healing microcapsules. This method does not need to prepare urea-formaldehyde prepolymer in advance, but directly forms the capsule wall of the microcapsules by polycondensation and solidification of urea and formaldehyde under acidic conditions. Ethyl acetate is used as the core material of the repair agent to form microcapsules.

[0044] Specificall...

Embodiment 1

[0059] Embodiment 1 self-healing microcapsule / epoxy resin TDCB sample

[0060] (1) Preparation of emulsifier solution: Add 1.25g of deionized water and 50g of ethylene maleic anhydride copolymer (EMA) into a beaker, stir the solution and heat it to 80°C for 1h to fully dissolve the EMA to obtain 2.5%EMA aqueous solution;

[0061] (2) Preparation of wall material solution: at room temperature, add 5.00g of urea, 0.50g of resorcinol and 0.50g of ammonium chloride into the reaction kettle, add 200g of deionized water to fully stir and dissolve the feed, and then add 50mL of the above steps (1) The prepared 2.5% EMA solution is fully stirred and mixed evenly, the pH of the obtained solution is 3.00 to 3.10, and the pH of the above solution is adjusted to 3.5 by using 5% NaOH solution;

[0062] (3) Microcapsule emulsification: Slowly add 45g of ethyl phenylacetate (restorative agent) to the solution prepared in step (2), stir with a high-speed shear emulsifier, the emulsification ...

Embodiment 2

[0066] Embodiment 2 microcapsule intelligent self-healing coating

[0067] (1) Preparation of emulsifier solution: Add 1.25g of deionized water and 50g of ethylene maleic anhydride copolymer (EMA) into a beaker, stir the solution and heat it to 80°C for 1h to fully dissolve the EMA to obtain 2.5%EMA aqueous solution;

[0068] (2) Preparation of wall material solution: at room temperature, add 5.00g of urea, 0.50g of resorcinol, and 0.50g of ammonium chloride into the reaction kettle, add 200g of deionized water to fully stir and dissolve the feed, and then add 50mL of the above steps (1) The prepared 2.5% EMA solution is fully stirred and mixed evenly, the pH of the obtained solution is 3.00 to 3.10, and the pH of the above solution is adjusted to 3.5 by using 5% NaOH solution;

[0069] (3) Microcapsule emulsification: Slowly add 45g of ethyl phenylacetate (restorative agent) to the solution prepared in step (2), stir with high-speed shear emulsifier, emulsification speed is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com