Torque control method of industrial robot

An industrial robot and control method technology, applied in program control, general control system, control/regulation system, etc., can solve the problems of low safety, inability to avoid obstacles effectively, and low control accuracy, and achieve the effect of high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described below in conjunction with the accompanying drawings.

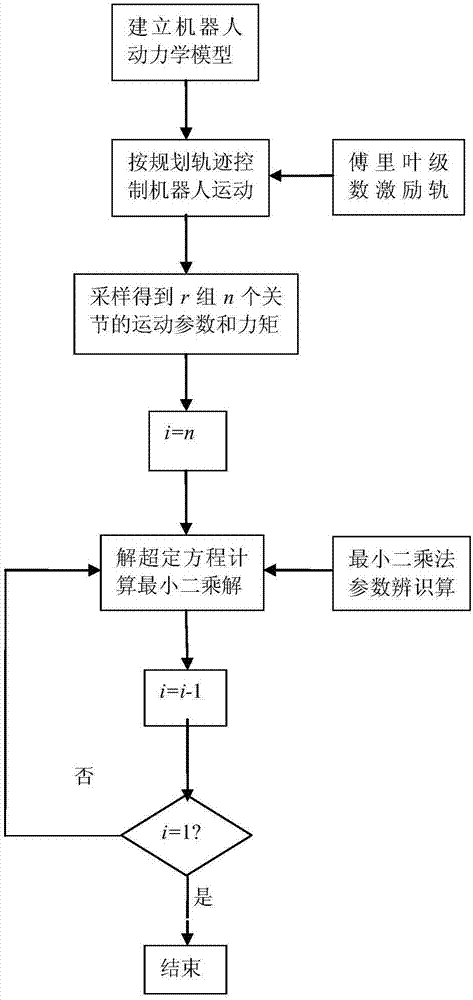

[0050] refer to figure 1 and figure 2, a torque control method for an industrial robot. First, an accurate robot dynamics model is established by identifying the kinematics and inertia parameters of each joint; then, the displacement of each joint angle when moving to the terminal posture is obtained by solving the inverse kinematics; finally, Taking the joint angular displacement as the motion distance, a sinusoidal jerk planning method is used to plan the velocity acceleration of each joint. The control torque in the motion path can be solved by substituting the velocity and acceleration into the dynamic model. The torque control method includes the following steps:

[0051] Step 1: Identification of dynamic parameters of industrial robots

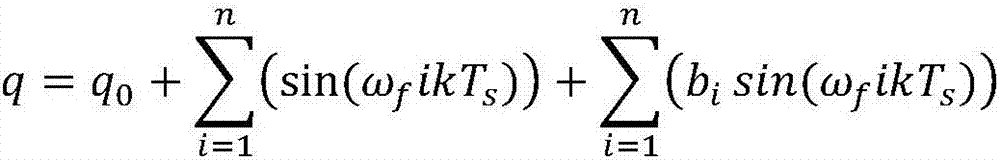

[0052] The present invention adopts the overall identification method of testing the whole robot to identify the dynamic p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com