Adjustable material shifting device

A bearing seat and roller technology, applied in the direction of transportation and packaging, conveyors, conveyor objects, etc., can solve the problems of reduced safety, equipment failure, material blockage, etc., to facilitate manual adjustment, smooth material transportation, and prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

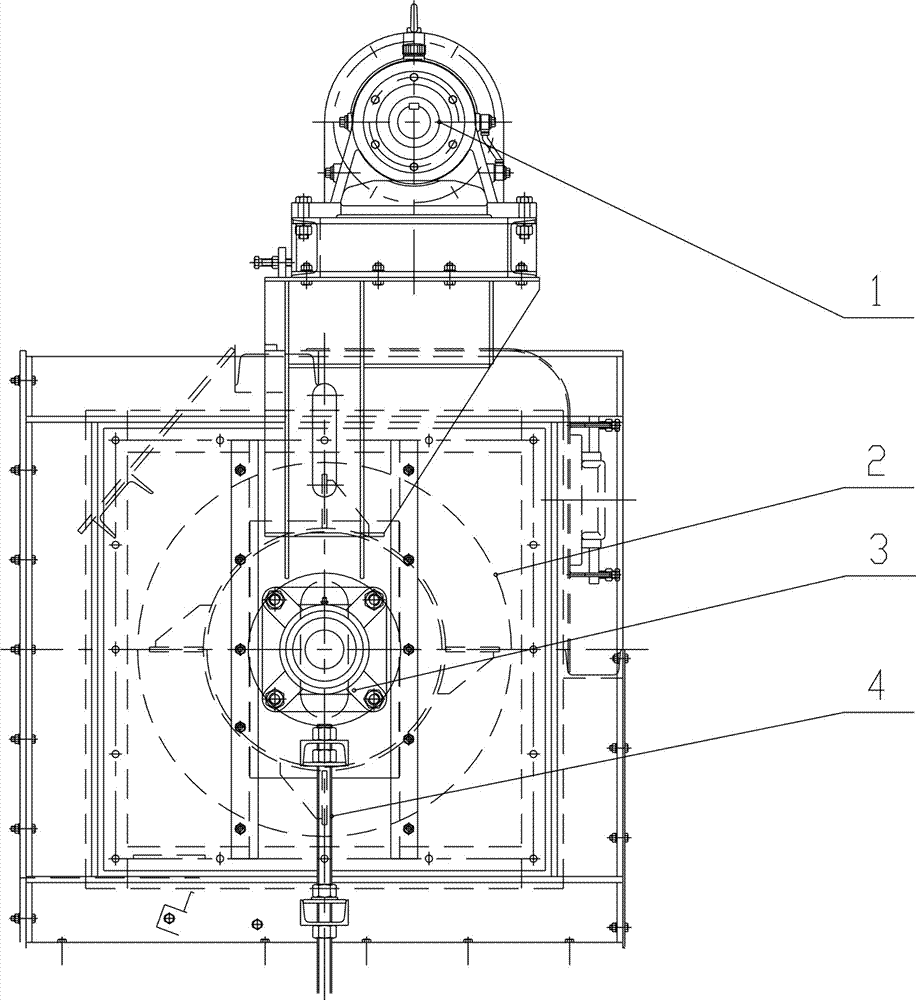

[0019] like figure 1 As shown, an adjustable material shifting device includes a drive unit 1, a roller 2, a bearing seat 3, and a screw rod 4. The drive unit 1 is connected to the roller 2, and the roller 2 is installed on the bearing seat 3, and the bearing seat 3 is provided with a nut. The screw mandrel 4 is threadedly connected with the nut of the bearing seat 3, and the up and down movement of the screw mandrel 4 drives the bearing seat 3 and the cylinder 2 to move up and down.

[0020] There is a certain distance between the bottom of the drum 2 and the working surface of the conveying mechanism.

[0021] The conveying mechanism is connected with a conveying motor, and both the drive unit 1 and the conveying motor are connected with an emergency stop switch.

[0022] The drum 2 is provided with a cutting blade.

[0023] Two nuts are arranged symmetrically on both sides of the bearing seat 3, and the two screw mandrels 4 are threadedly connected with the two nuts of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com