Preparation and use method of alkali remover for porous planting concrete

The technology of concrete and alkali agent is applied in the field of preparation of alkali remover for porous ecological planting concrete, which can solve the problems affecting the promotion and application of porous ecological planting concrete, affecting the growth of porous ecological planting concrete, plant root rot, etc. Dense, fast hydration, avoids the effect of continuous generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] First, weigh 5% slow-release salt sodium bicarbonate, 5% sodium stearate, 5% ferrous sulfate, 25% lignosulfonate and 60% microsilica according to the mass percentage, and place it in a planetary In the pulverizer, grind for 30 minutes at a speed of 300 rpm, use a cement negative pressure sieve and a nitrogen adsorption specific surface area measuring instrument to measure its fineness and specific surface area, and obtain 3% of the 45 μm sieve, with a specific surface area of 11000 cm 2 / g alkali removal agent.

Embodiment 2

[0032] First, weigh 3% slow-release calcium bicarbonate, 8% calcium stearate, 5% copper sulfate, 22% polycarboxylate dispersant and 62% microsilica fume according to the mass percentage, and place them in a planetary In the pulverizer, grind for 32 minutes at a speed of 250 rpm, use a cement negative pressure sieve and a nitrogen adsorption specific surface area measuring instrument to measure its fineness and specific surface area, and obtain 2% of the 45 μm sieve, with a specific surface area of 11400 cm 2 / g alkali removal agent.

Embodiment 3

[0034] First, weigh 4% slow-release calcium bicarbonate, 8% calcium stearate, 4% copper sulfate, 24% polycarboxylate dispersant and 59% microsilica fume according to the mass percentage, and place them in the planetary In the pulverizer, grind for 35 minutes at a speed of 200 rpm, use a cement negative pressure sieve and a nitrogen adsorption specific surface area measuring instrument to measure its fineness and specific surface area, and obtain 3% of the 45 μm sieve, with a specific surface area of 12000 cm 2 / g alkali removal agent.

[0035] Alkali remover use method 1:

[0036] The mix ratio of porous concrete is as follows: Unit: kg / m 3

[0037] cement Aggregate (26~31.5mm) conventional additives Alkali remover 180 1450 5 3

[0038] After using the alkali remover, the effect is as follows:

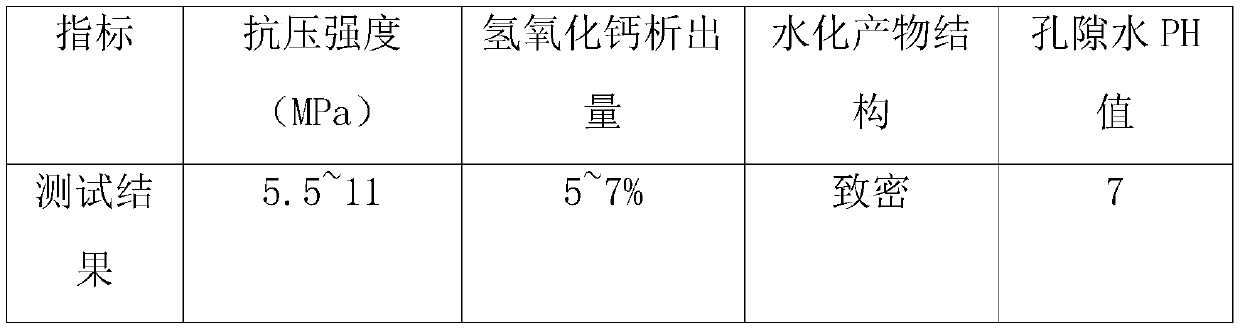

[0039]

[0040] Alkali remover use method 2:

[0041] The mix ratio of porous concrete is as follows: Unit: kg / m 3

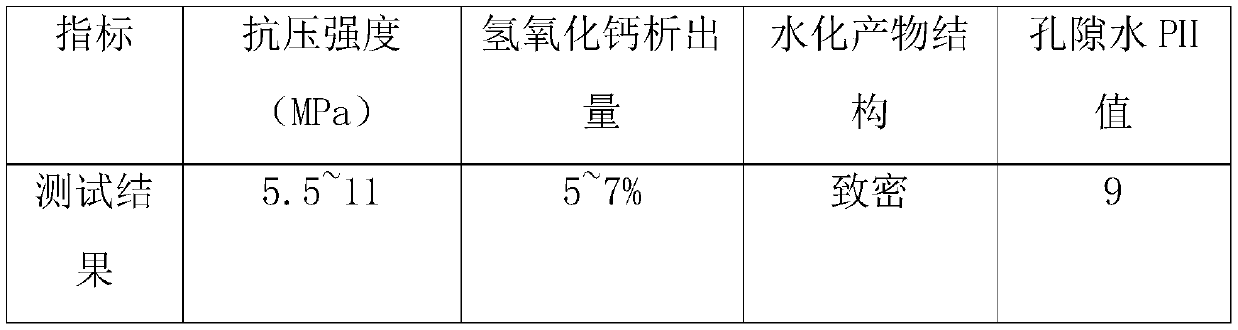

[0042] cement Aggreg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com