Large-air-volume high-pressure-head centrifugal fan

A technology of centrifugal fan and high-pressure head, which is applied to components of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc. It can solve the problems that centrifugal fans are difficult to meet the space adaptability of fans, and achieve a solution The effect of air movement problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0013] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

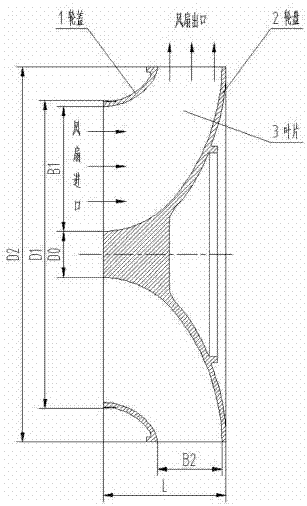

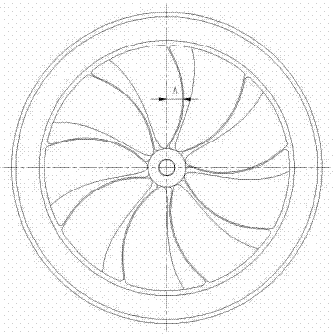

[0014] In order to solve the problems of the prior art, the present invention provides a centrifugal fan with a large air volume and a high pressure head, which includes: a wheel cover 1, a wheel disc 2 and blades 3;

[0015] The wheel cover 1, disc 2 and blades 3 form a closed fan impeller, the axial length is short, the maximum outer diameter of the fan D2 / the axial length L of the fan is between 2.7 and 3.2; the hub ratio is small, the hub diameter D0 / fan Inlet diameter D10.8; can continue to work stably at high speed, rated working speed>4000r / min; and has a large air volume and hig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com